- Masterpiece in the world 2018/01/23 UP

-

Masterpiece in the World #16

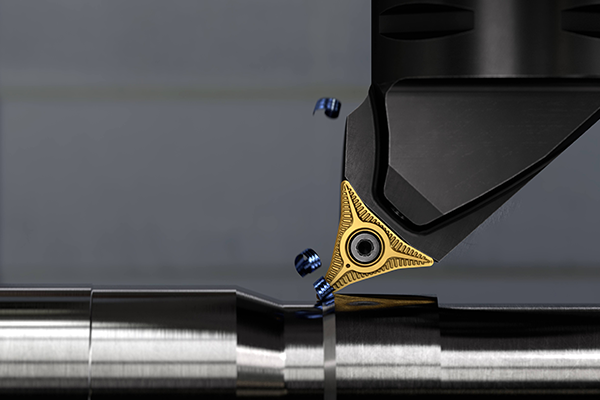

All-directional turning tools that extend tool life and boost productivity

- Tag

-

- Tool

- Turning

Shaft-shaped workpieces are mainly mass-produced by turning on turning centers or integrated mill turn centers. In such turning, reduction in machining time and extension of tool life are issues to tackle. This time we introduce an all-directional turning tool “CoroTurn®Prime” from Sandvik that shortens machining time and extends tool tip life.

Solution for machining issues of shaft-shaped workpieces

In the conventional turning of shaft-shaped workpieces, the cutting angle of a tip is a nearly right angle from 93 to 95 degrees. So increasing feedrate is difficult, and a load imposed on tips is enormous. In general, a cutting angle is reduced to enlarge a contact surface between a tip and a workpiece, aiming to increase feedrates. As this cannot be applied to standing wall machining, the cutting angle has to be returned again, and the feedrate needs to be reduced when standing wall machining is done. The all-directional turning tool “CoroTurn®Prime” from Sandvik solves such an issue.

The “CoroTurn®Prime” for all-directional turning to drastically improve productivity

This content is for members only