- Products 2024/05/13 UP

-

Our health monitoring service detects signs of failure early on, and can significantly reduce downtime

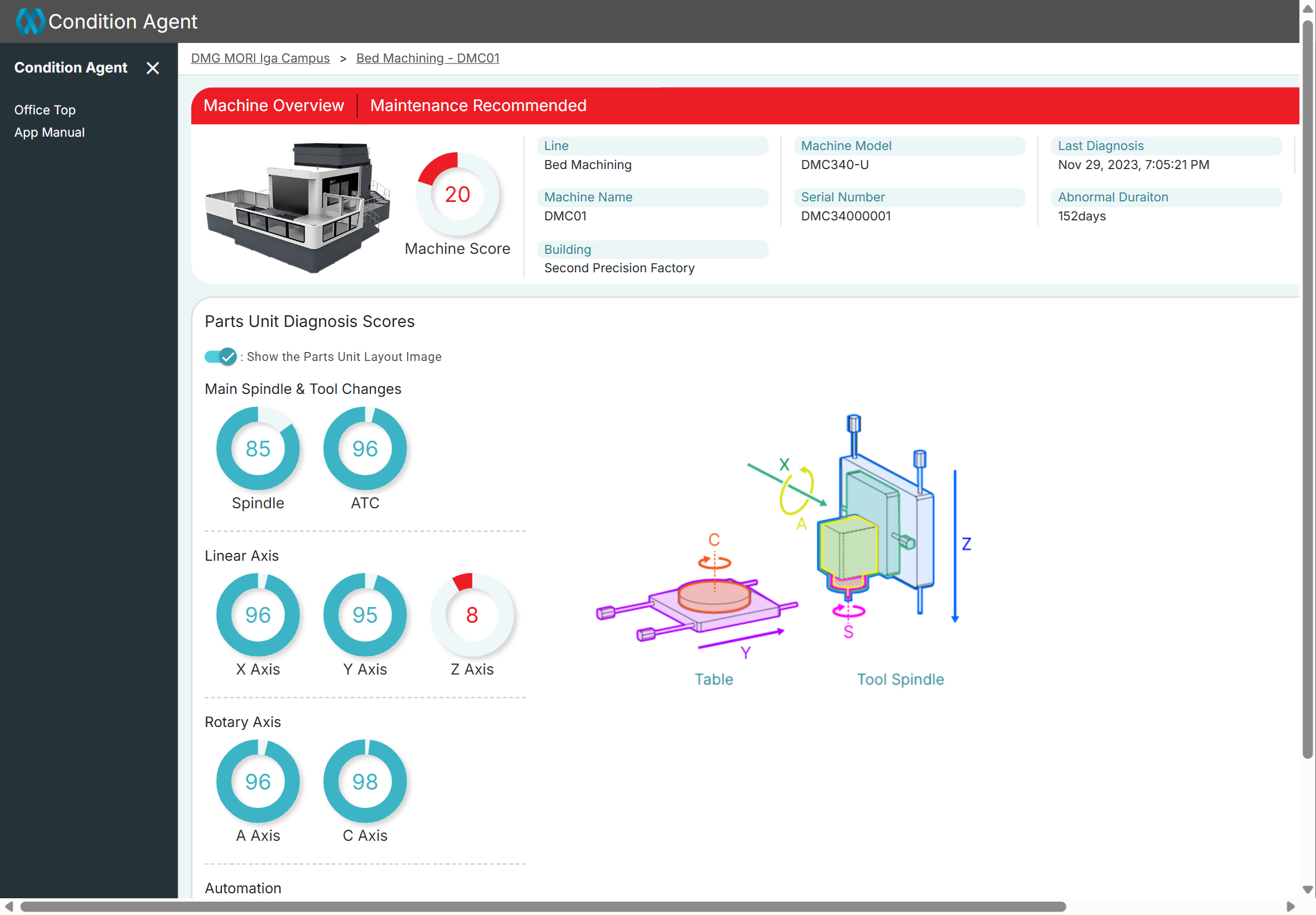

Condition Agent is a health monitoring service that periodically and predictively diagnoses abnormalities in machine tool spindles and feed shafts, and provides reporting functionality to discover signs of failure early on, allowing you to perform preventative maintenance and reduce machine downtime.

Condition Agent can be used to bring DX to maintenance activities, so that machine tools can continue to be used in normal working order longer, improving productivity and helping to realize a sustainable society.

Main applicable models

- 5-axis Machining Centers DMU/DMC series, DMU/DMC monoBLOCK series, DMU/DMC(FD)duoBLOCK series, INH series, NMV series

- Multi-axis Machines NTX series

- Machining Centers NVX series, NHX series, CMX series, i series

- Turning Centers NLX series, NZX series

Main benefits

(1) Predictively diagnoses spindle and feed shaft abnormalities to detect abnormalities early on and reduce failure downtime

Condition Agent makes diagnosis easy. Machine status data is stored in the cloud in order to conduct accurate analysis, allowing signs of failure to be detected early on.

Diagnosis results can also be checked using a dedicated web application.

Web application screen (shaft analysis results)

(2) Quick installation

Condition Agent can be easily installed to existing machine tools using the special Condition Agent Kit. Setup takes less than an hour. Once setup is complete, simply run the provided NC program to diagnose the machine immediately.

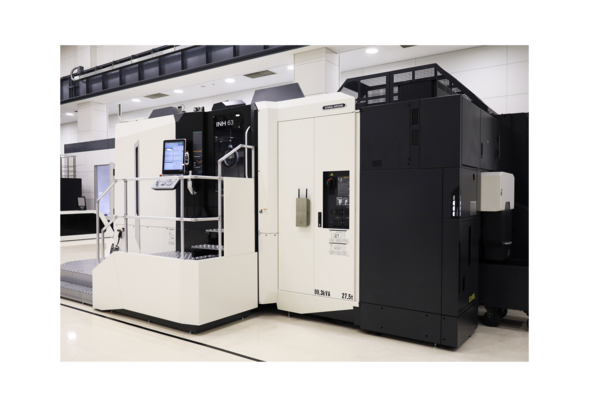

Installed on machine (INH 63)