- Products 2024/01/08 UP

-

Wide range of measurement functions to help write programs quicker

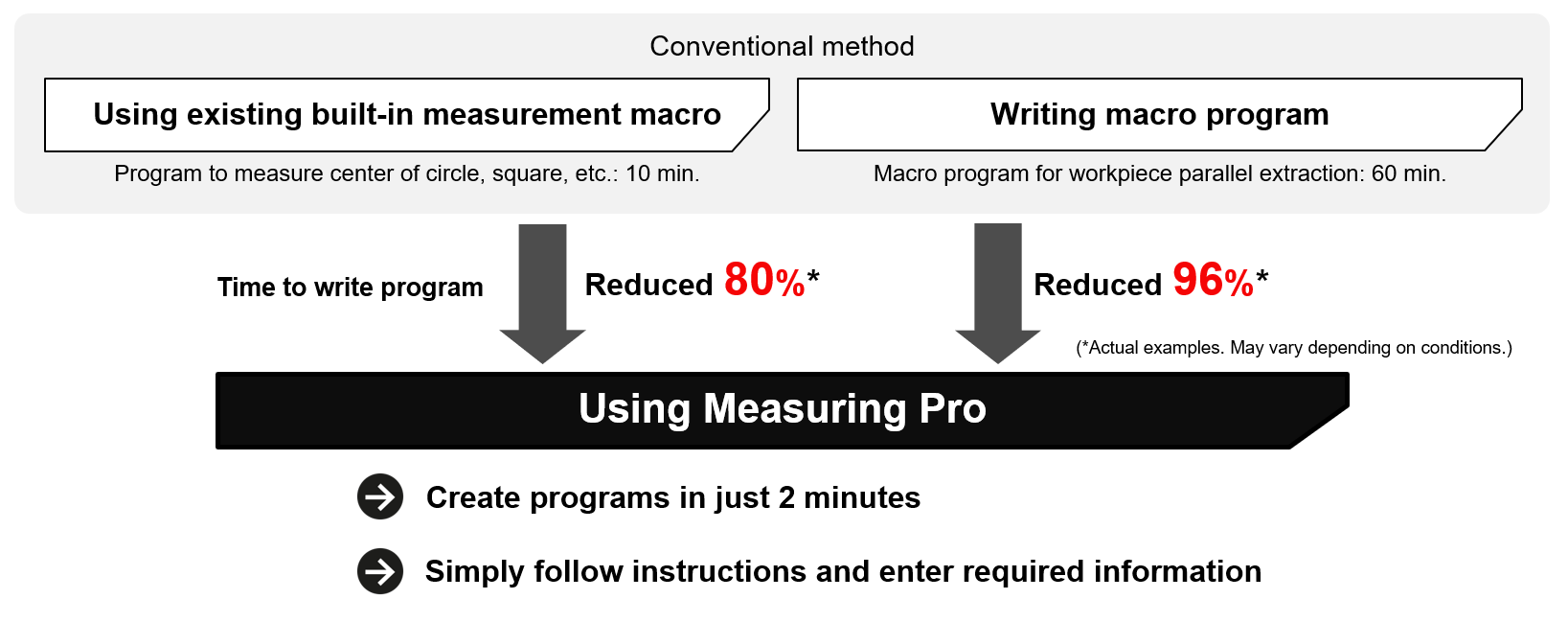

Measuring Pro is a technology cycle that helps to program measurement work and reduce time spent on setup. Measurement programs can be written easily through interactive dialogue, reducing the burden on operators.

Compatible machine models

- INH Series

- NTX Series

- NVX Series

- NHX Series

- NLX Series

Development background

As workpieces become more complex and precise, measurement processes are becoming more complicated and advanced. Most customers input G code and write macro programs to support measurement work. This often involves checking manuals for machine system variables required for workpiece coordinate measurement and correction, and confirming that measurement operations and results are correct after writing the program. This increases the burden on operators and the time required for setup.

DMG MORI developed "Measuring Pro" so that anyone can easily and quickly write measurement programs, for a higher level of machining and measurement quality.

Unique selling points

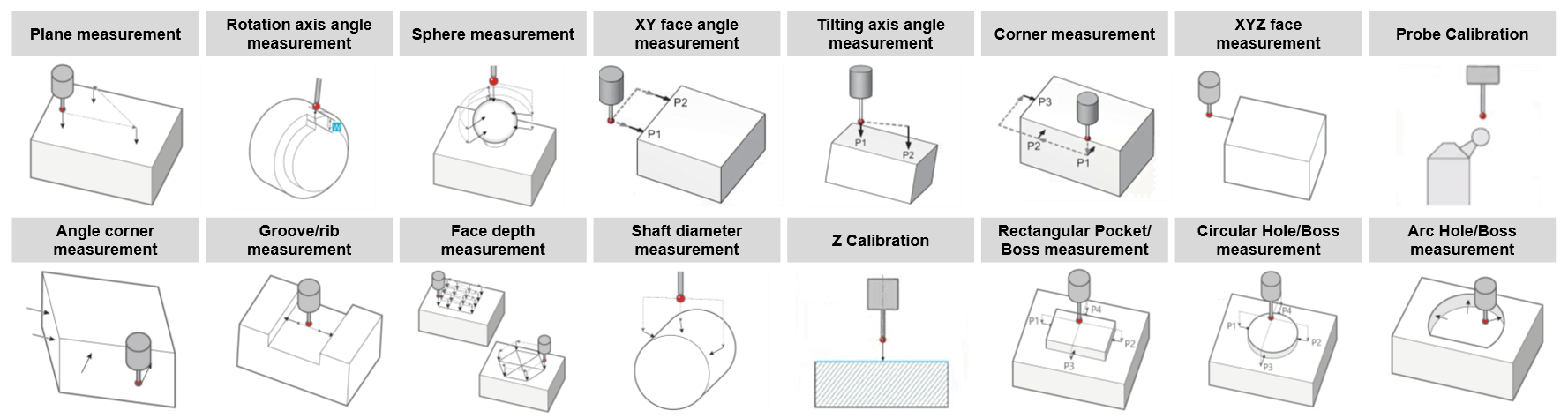

1. Wide range of measurement cycles included

Measuring Pro supports a wide range of measurement cycles with 16 types*1 of measurements including not only standard measurements such as XYZ plane measurement, but also complex measurements such as shaft measurement and rotary axis phase measurement.

*1 For INH Series. The number of cycles varies depending on the machine model and specifications.

Wide range of measurement functions

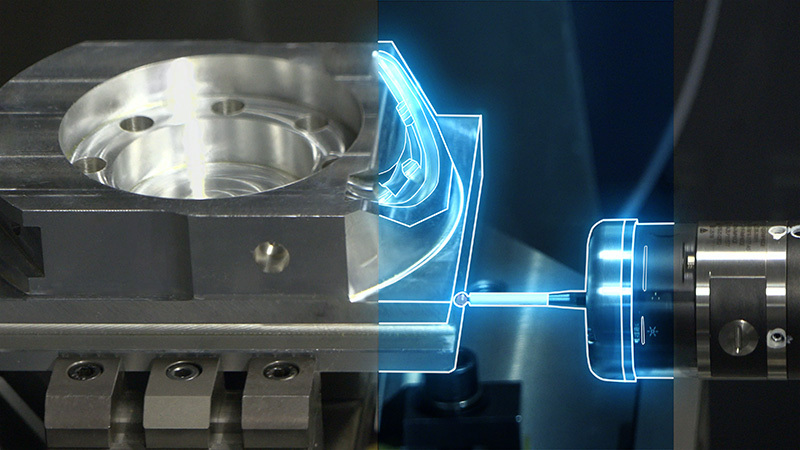

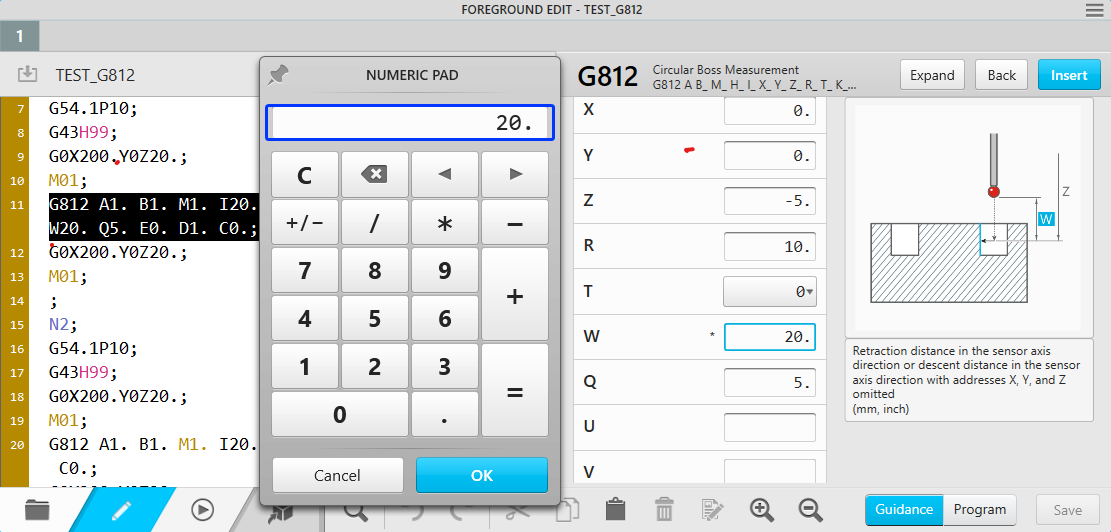

2. Interactive programming

The CELOS screen provides guidance throughout the programming process, allowing the user to write measurement programs simply by entering required information. Programming is performed interactively and requires no specialized skills or calculations, allowing users to write programs quickly.

Significantly less time spent programming

Interactive input

3. Perform correction work safely and easily

The correction feedback function automatically inputs correction values after measurement, making it easier to perform correction work and prevent entry mistakes. The alarm stop functions stops the machine if a value falls outside of the set range, to prevent interference accidents from happening.