- Products

-

New Technology Cycle against Chip Troubles

Chips are broken into small pieces to eliminate chip problems.“Chip Breaking” is the perfect solution for cutting chip-caused troubles and frees customers from redundant chip removal work, thus drastically reducing time and cost.

Main Applicable models

- NLX series

- NTX series

- NZX series

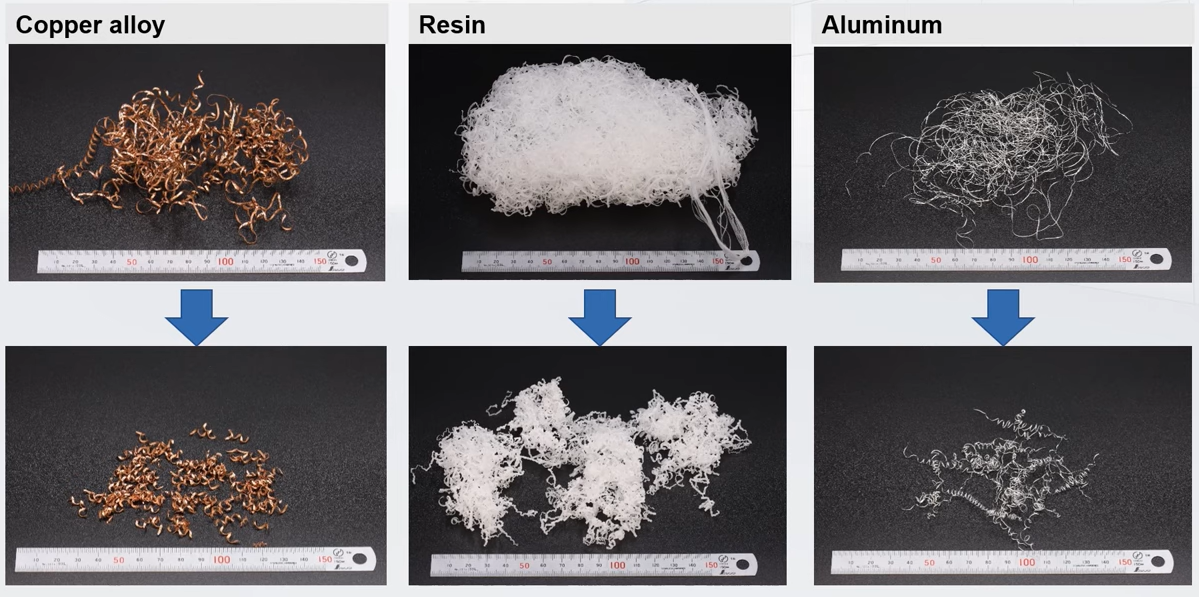

Chip Comparison

Unique selling points

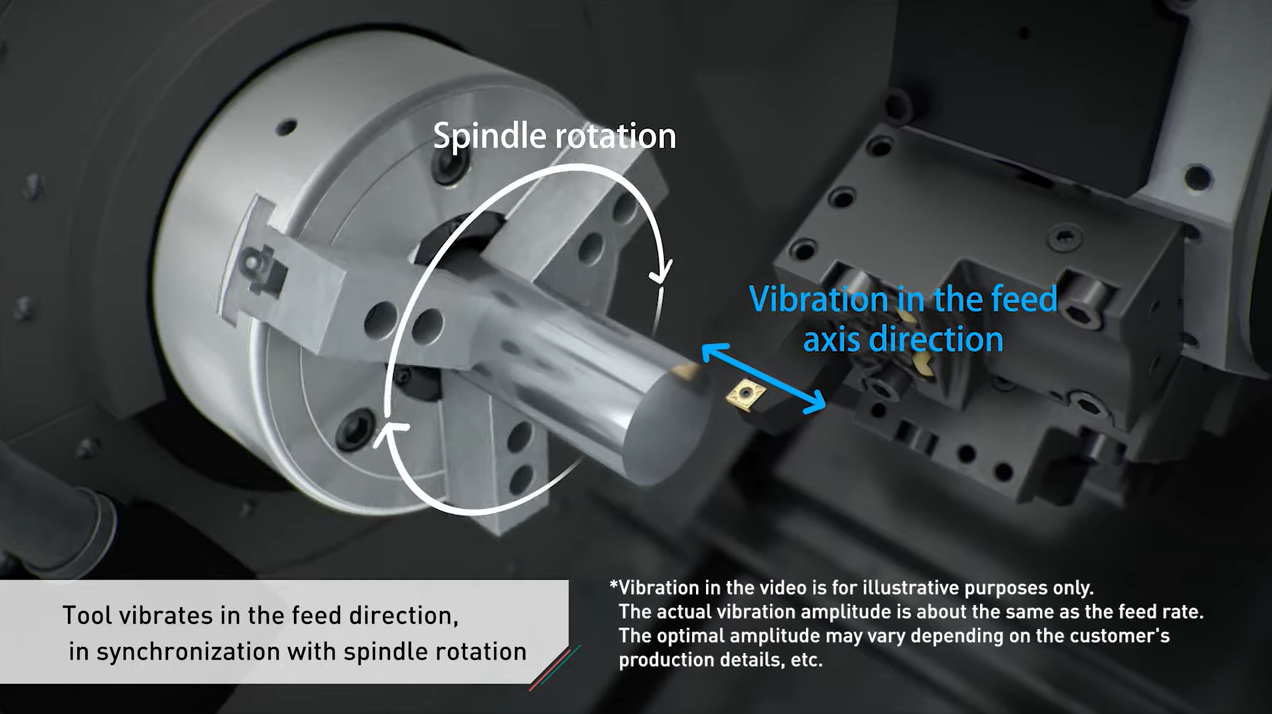

1. Effective break up of cutting chips during machining

- Feed axis vibration in synch with spindle rotation to break up chips

- Chip length adjustable by setting different vibration frequencies per spindle rotation

- No coolant needed for chip break up

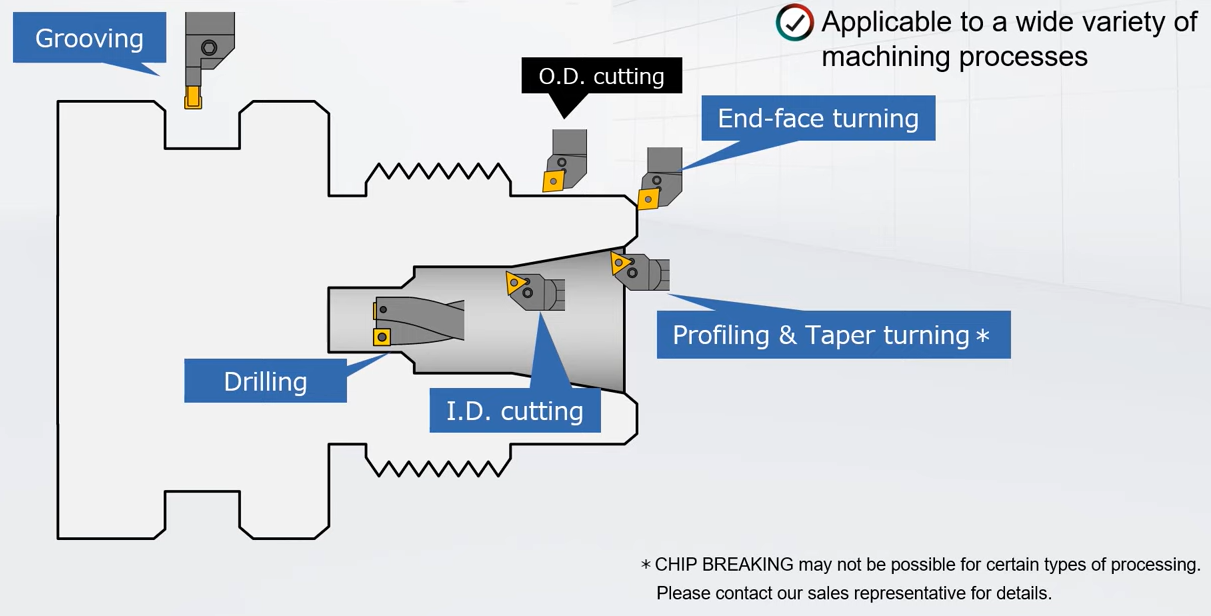

2. Applicable to various processes and materials

- Available for grooving, drilling, outer/inner diameter machining and others*

- Effectively breaks up long chips from resin, pure copper and pure aluminum as well

- * Only vibration in 1 axial direction can be machined.

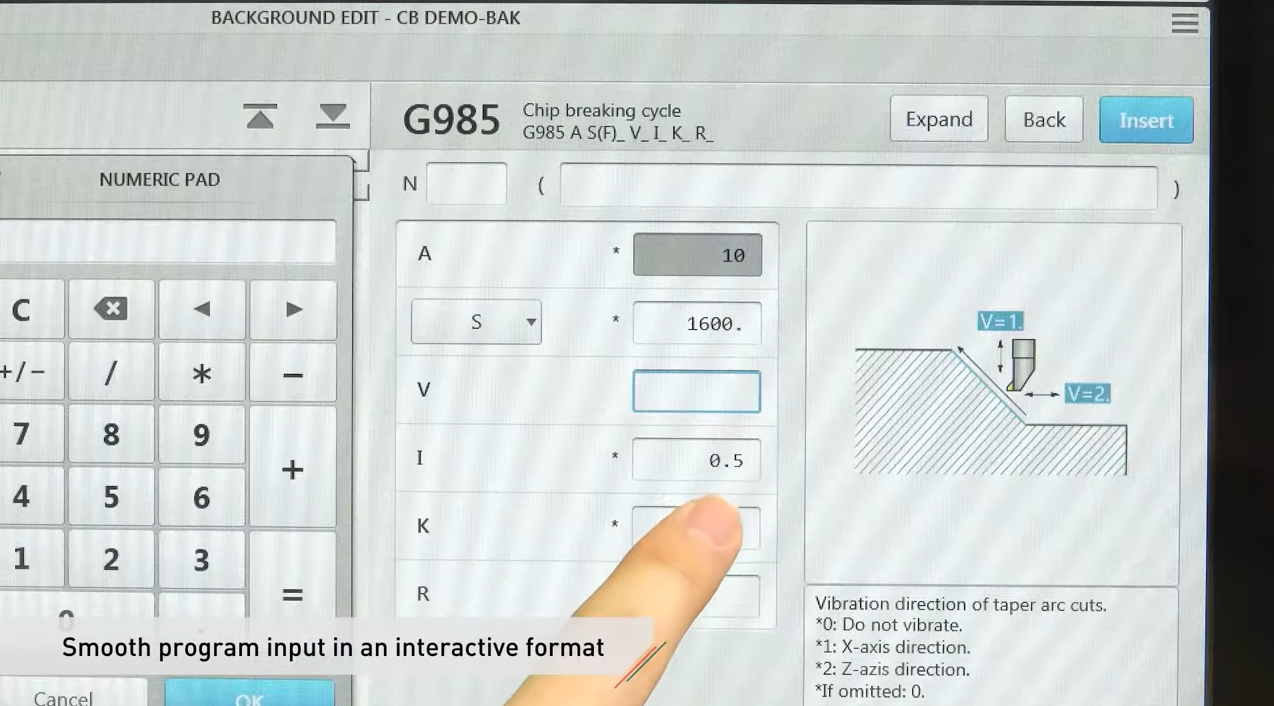

3. Easy programming with interactive guidance

- 80% shorter programming time

- Possible to predict in-process vibration and confirm safe cutting conditions

- Automatic control of cutting conditions to suppress excessive vibrations