- Products 2024/09/16 UP

-

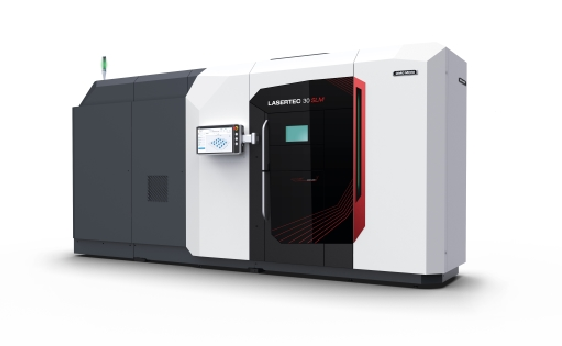

Up to 4 laser oscillators for 1.5x more build volume! Additive Manufacturing by using powder bed

LASERTEC 30 SLM 3rd Generation is a process in which powder material is built up layer by layer and then selectively melted by laser. This is also called “powder bed process. This is the first AM machine that utilizes a cast iron frame with thermo symmetrical structure for high rigidity as well as Magnescale’s scale on the Z-axis to improve positioning accuracy. Furthermore, the 80 µm laser spot diameter and the high-precision optical module for the entire build area allow for deposition in a space of 325 x 325 x 400 mm3 – 1.5 times larger before. A maximum of four powerful laser oscillators with up to 1,000 W accelerates the process.