- Products 2022/05/23 UP

-

Minimize Chattering by Controlling Spindle Speed

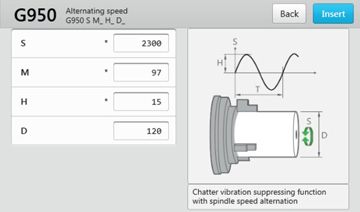

Alternating speed minimizes vibration during turning by periodically changing spindle speeds. It is the optimal solution for machining of long, easy-to-chatter workpieces such as shafts.

Main Applicable models

- CTX Series

- CTX TC/CTX TC 4A series

- DMU/DMC FD duoBLOCK series

- DMU eVo series

- ALX、NLX、NZX、NTX series

Background of Development

Even under the recommended cutting conditions for tools, chattering can occur and affect machining accuracy and efficiency. In such a case, spindle speeds are adjusted as a general solution, but the programs are very complex and take a certain time to create. So DMG MORI has developed Alternating speed that supports easy creation of the programs for minimizing chattering in a short time.

Unique Selling Points

1.Versatility

Alternating speed is available on many models, such as turning centers or 5-axis FD machines equipped with a direct drive table.

2.Conversational programming

Operators can create the programs that increase/decrease the spindle speed simply by inputting parameters, while checking the graphics displayed on CELOS, an HMI. Inputting parameters does not require any special skills. As the programming is done by the conversational method, the programs can be created in a short time.

3.Reduction in investment costs

Boring bars or steady rests can also control chattering, but as Alternating speed minimizes chattering by programs, it can cut down investment costs for additional peripheral equipment and facilities.

<SIEMENS>

<MAPPS>

Inputting of rotation periods