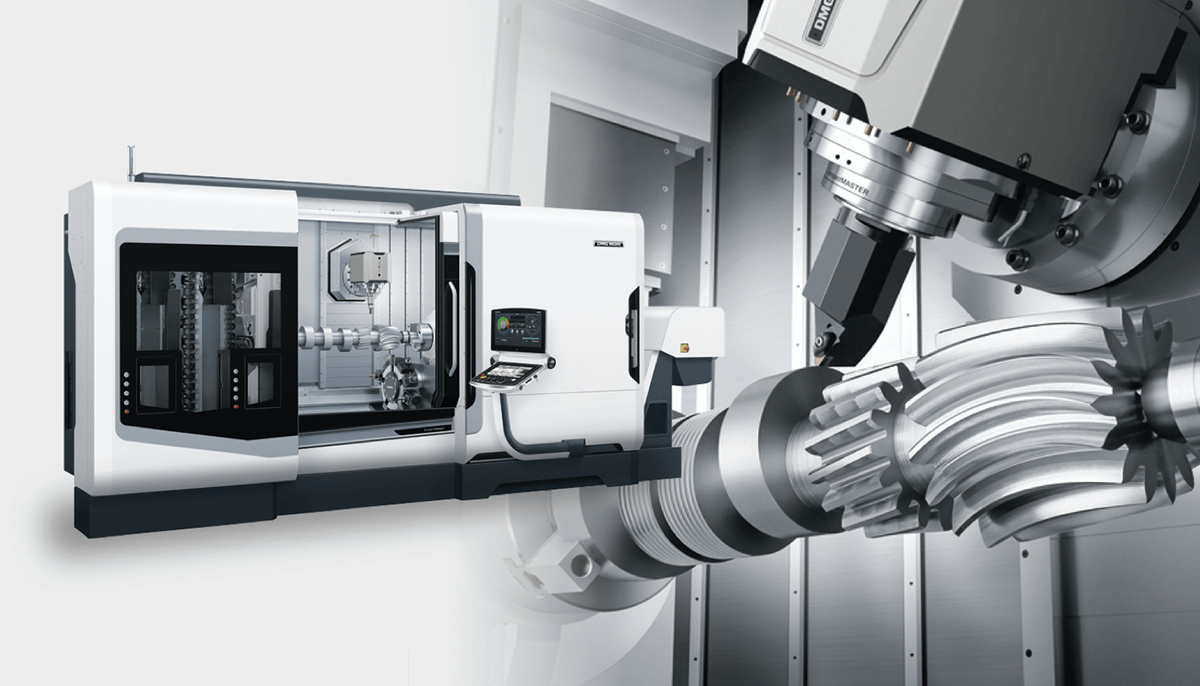

5-axis control machining/process integration

As a result of advancement of machine tools, technological innovations of 5-axis control and mill-turn machines are occurring to realize highly accurate and highly efficient machining.

DMG MORI offers various peripherals and solutions as well as machine tools capable of 5-axis control and mill-turn machining.

What's 5-axis control machining / Process integration?

Advantages of 5-axis control machines

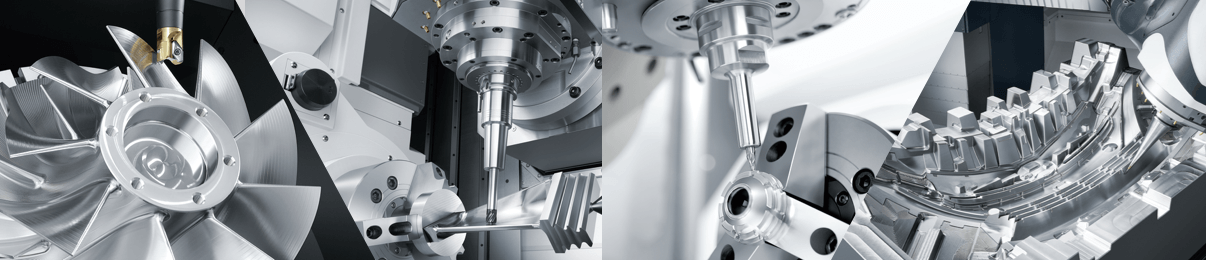

A 5-axis control machine has three linear axes (X-, Y-, and Z-axis) and two additional axes (swivel-rotary axis) to ensure a higher level of flexibility in machining.

Additional rotary axes can help reduce frequency of setup work and machining times, and increase machining accuracy and quality as multiple areas can be machined in one setup.

The machine is often considered only for special-shaped parts for aircrafts, but it actually brings more advantages than a 3-axis machine in machining of dies and molds which requires high-quality surfaces, and workpieces of general shapes.

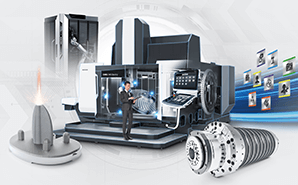

Advantages of mill-turn machines

A mill-turn machine is equipped with the turning function of turning centers and milling function of machining centers to perform both types of machining operations on one machine tool.

With a combination of turning and milling capabilities, the machine is able to cut complex-shaped workpieces in the aircraft, medical equipment, automotive, die & mold and precision equipment sectors with high accuracy and efficiency. The mill-turn machine also allows process integration, space saving and even automation, achieving higher productivity.

-

Video

2025/02/13

NTX 2000 / 2500 / 3000 3rd Generation Coming soon! Process Integration machine

- 0 View

- 0

-

Ví dụ về trường hợp khách hàng

2025/02/07

GIA CÔNG BÁNH RĂNG TRÊN MÁY TIỆN PHAY

- 250 View

- 0

-

Ví dụ về trường hợp khách hàng

2025/01/16

VƯƠN TỚI KHÔNG GIAN với Gia công 5 Trục và Tiện-Phay

- 471 View

- 1

-

Ví dụ về trường hợp khách hàng

2024/12/13

Phay, Tiện và Mài trên Một Máy

- 551 View

- 0

-

Video

2024/11/14

Process integration of gear machining「Gear Production⁺ by NMV 5000 DCG」

- 0 View

- 0

-

Video

2024/05/31

Heavy duty machining with INH 63

- 174 View

- 0

-

Video

2024/05/30

Machining of spiral bevel gears with INH 63

- 147 View

- 0

-

Tin tức/chủ đề

2024/05/13

DMG MORI Online Seminar

「5-Axis Machines with Siemens Control: Enhanced Productivity with Simple 3-Axis Programming」- 501 View

- 1

-

Ví dụ về trường hợp khách hàng

2024/03/20

ECOCOOL 3000-DMJ, a high-performance coolant that can increase factory productivity and even improve work environments

- 677 View

- 0

-

Video

2024/02/08

Learn Mill-turn Machining with 30 Workpiece Examples! 【 Process Planning Adviser 】

- 0 View

- 0

-

Video

2024/01/19

"NTX 500" Space-Saving Integrated Mill Turn Center for small complex-shaped workpieces

- 436 View

- 0

-

Tài liệu hội thảo

2023/11/23

MX Guidebook Vol.2

Mastering 5-Axis Machining with CAM - for advanced workpieces -- 1469 View

- 1