- Top page

- DMG MORI MX

- Process Integration

PROCESS

INTEGRATION

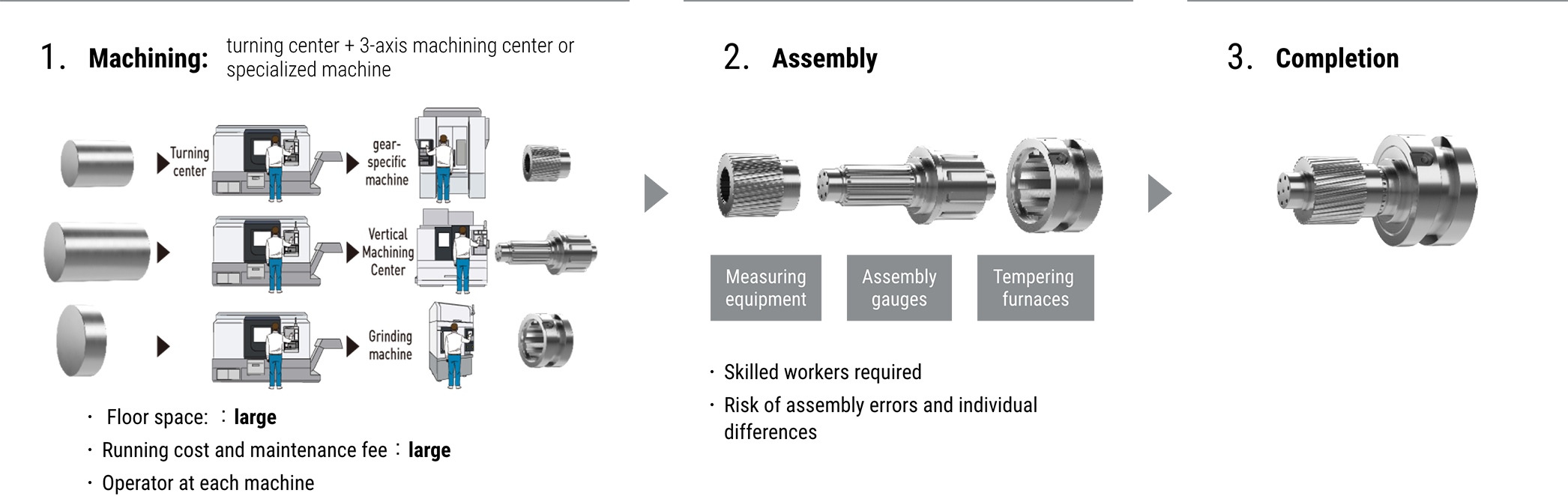

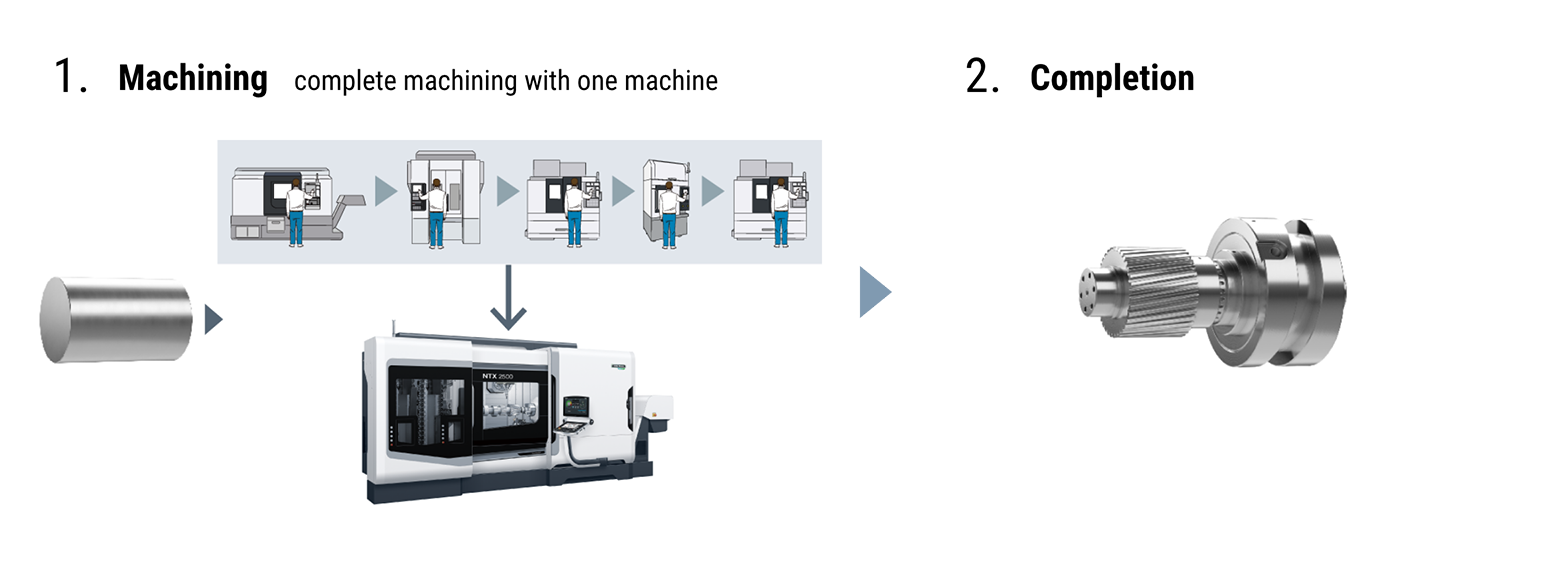

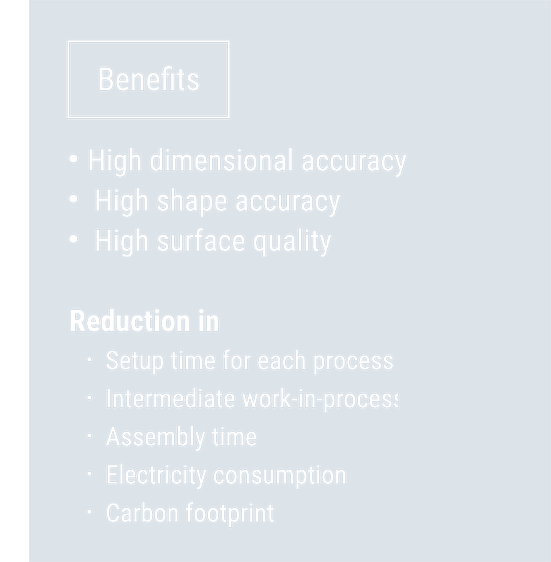

Against the backdrop of societal changes such as the shortage of engineers and operators and the rise of high-mix low-volume production, DMG MORI has effectively met customer demands for process-integration machines. This demand has notably surged since the 2010s. Consequently, process-integration machines, represented by 5-axis machines and mill-turn centers, have become the primary drivers of our order intake. DMG MORI will continue contributing to the automation and digital transformation of the manufacturing industry by delivering process-integration machines.

Majority of Orders Stems From Process Integration and Advanced Machines

Against the backdrop of societal changes such as the shortage of engineers and operators and the rise of high-mix low-volume production, DMG MORI has effectively met customer demands for process-integration machines. This demand has notably surged since the 2010s. Consequently, process-integration machines, represented by 5-axis machines and mill-turn centers, have become the primary drivers of our order intake. DMG MORI will continue contributing to the automation and digital transformation of the manufacturing industry by delivering process-integration machines.