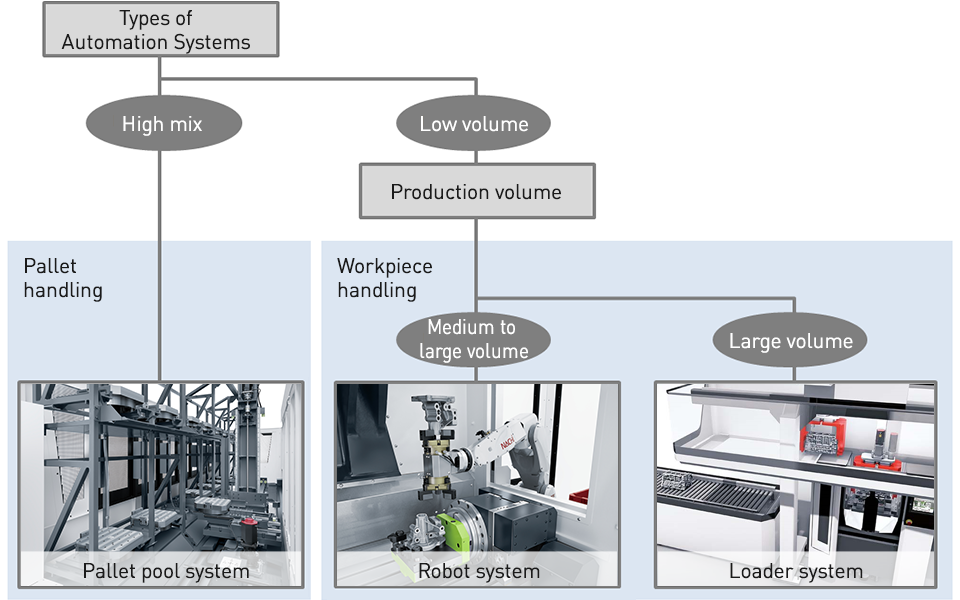

Types of Automation Systems

Building Automation Systems

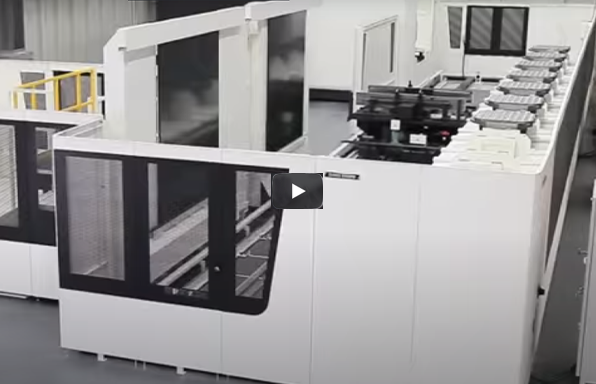

DMG MORI produces automation systems by combining a machine tool body such as a turning center (CNC lathe) and a machining center with peripheral equipment such a robot and a loader. You can adopt automation at a scale necessary for your shop, for example, from automation of only one machining process to an entire shop floor. What is important is that you choose the automation system appropriately suited to your workpieces, production capacity and requirements.

In general, automation systems can be divided into three types according to workpieces and production capacity.

As various other automation solutions are also available to tackle your production problems, please feel free to contact us.

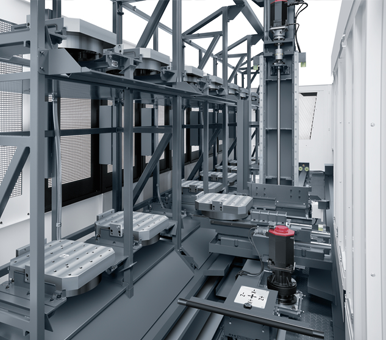

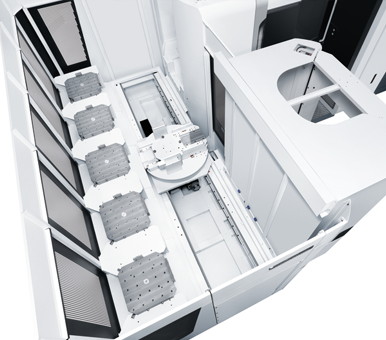

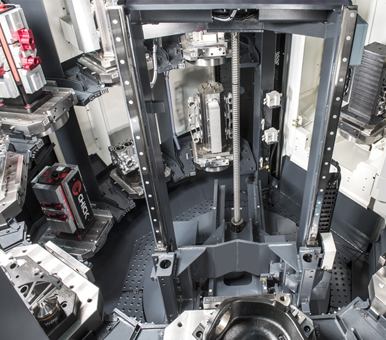

Pallet pool system

-

Transfer method: Workpiece transfer on the pallet

Advantage: Each pallet transfers different shapes of

workpieces and fixtures

Suited to: Automation of high-mix workpiece handlinhg

■ DMG MORI pallet pool system lineup

Three types of pallet pools are available according to workpiece types and lot numbers

-

- LPP (Linear Pallet Pool)

-

Product information

-

- CPP (Compact Pallet Pool)

-

Product information

-

- RPS (Rotary Pallet Storage)

-

Product information

Customer success story (Akitani Iron Works)

Akitani Iron Works is a manufacturer of components for machines and structures such as semiconductor equipment and robots.

The company, with some 40 employees, machines 300 to 400 kinds of components per month.

They introduced automation systems to streamline their high-mix low volume production 10 years ago, and recently combined the system with IoT solutions to further increase productivity.

Their success is drawing attention from the industry.

-

Front runner company of high-mix low volume production <Part 1>

Read the article

-

Front runner company of high-mix low volume production <Part 2>

Read the article

-

Front runner company of high-mix low volume production <Part 3>

Read the article

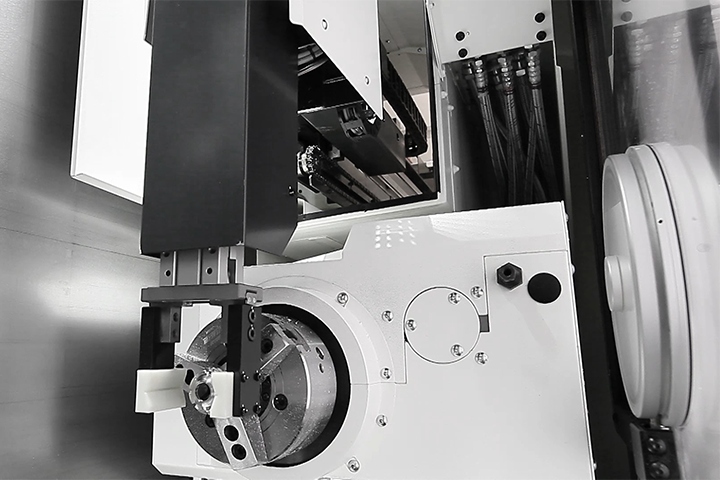

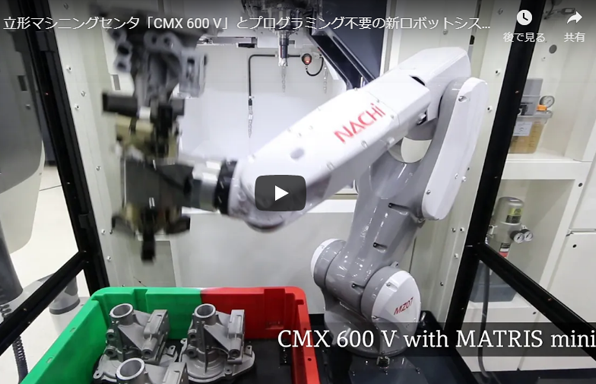

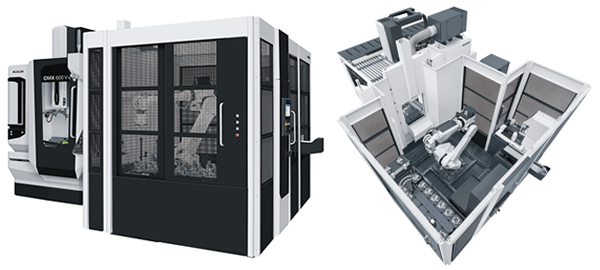

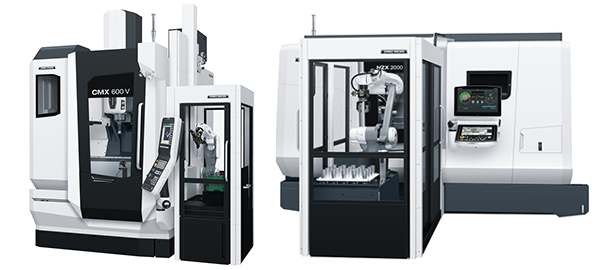

Robot system

-

Transfer method: Workpiece transfer by a multi-joint robot

Advantage: Easy collaboration with measuring systems and

peripheral equipment

Suited to: Automation that includes cell production and

pre / post processes

■ Example of using DMG MORI robot system

-

- MATRIS

-

-

- MATRISmini

-

Customer success story (Fuji Metal Co., Ltd.)

Fuji Metal Co., Ltd., with its headquarters located in Kawasaki City, Kanagawa, is a front runner manufacturer of semiconductor target materials.

They dominate an overwhelming share in the sector. Inside the factory, cutting-edge automation equipment is lined up, running 20 hours a day during night and weekend without human intervention.

They implement an effective way of working by letting the employees go home at the regular time, while maintaining the same high level of pay.

-

【Multi-axis Machine x Ask the Master of Robots】

(Read the article)

Vol. 1: How Fuji Metal achieved overwhelmingly high productivity

Vo. 2: Three points to overcome difficulties for process integration

Vol. 3: What is the ideal beyond process integration? -

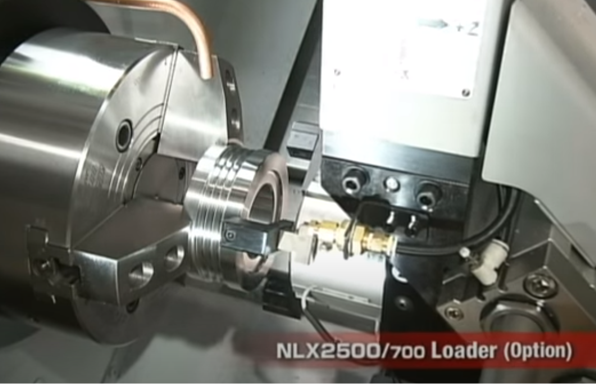

Loader system

-

Transfer method: Workpiece transfer by a transfer robot

Advantage: Entire process from material supply to discharge of

finished products can be completed on one machine,

and high-speed transfer of the same workpieces is

also possible.

Suited to: Automation of mass production machining

■ Example of using DMG MORI loader system

-

- Gantry loader

-

-

- Workpiece unloader

-