- Customer Case Example 2018/04/05 UP

-

Machine operators at the cutting-edge factory work on an annual salary

Introducing a work style that allows workers to leave work on time every day

Fuji Metal Co., Ltd. Headquarters Building (Kawasaki City, Kanagawa)

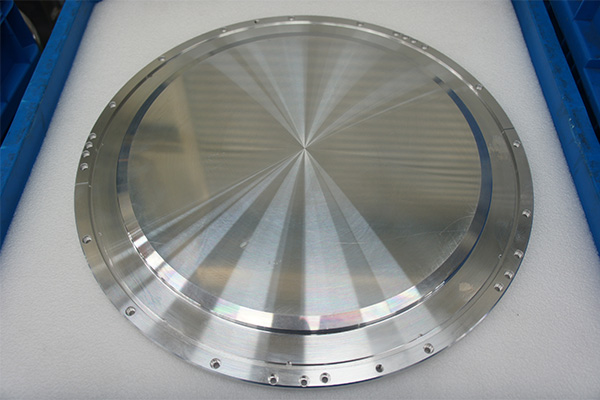

Fuji Metal specializes in the machining of nonferrous metals. The majority of the company’s sales comes from the manufacture of target materials used in sputtering equipment, which are vital for the manufacture of semiconductors. Sputtering refers to a process whereby film is deposited onto a semiconductor, which requires the use of a broad range of target materials, including titanium, copper, tantalum and cobalt, depending on what is to be coated. This requires specialist machining know-how in handling materials that can be particularly hard, adhesive, or fragile when compared to iron and other common machining materials. This is a field in which Fuji Metal has carved out an unrivaled position.

The company established new factories near its headquarters every two years in recent years, with its seventh factory equipped with state-of-the-art facilities just completed. Even so, the number of orders the company receives continues to outpace this growth. “Recently we are seeing demand double our expectations,” reveals Fuji Metal President and Representative Director, Mr. Masatoshi Fujii.

Sample workpiece with target material

The company raised the salaries of operators working at the cutting-edge factory by employing the annual salary system. An overtime pay of two hours is included in their salaries regardless of whether the equivalent work is performed or not. By implementing unmanned operation during night hours and on the weekend, the company has been able to send its workers home at the regular shift end time of 4:45 PM without issue.

How was Fuji Metal able to achieve such staggering levels of productivity?

President and Representative Director, Mr. Masatoshi Fujii

Shifting From Iron to Nonferrous Metals - Initial Attempts at Continuing Conventional Means of Production

This content is for members only