Features of DMG MORI Automation Systems

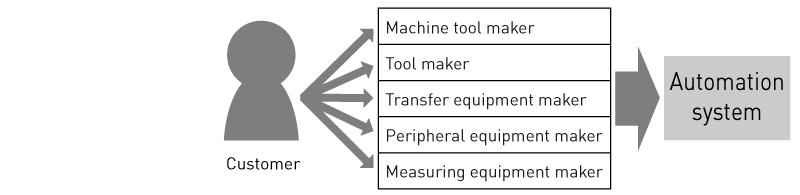

1. Single-source turnkey provider

DMG MORI arranges peripherals on your behalf to help reduce your burden of dealing with individual peripheral suppliers.

■ Other machine tool makers・・・Peripherals need to be arranged by customers themselves

■ DMG MORI・・・Peripherals are arranged by DMG MORI

2. System Solution Plant

The System Solution Plant, located in the Nara Campus, is dedicated to turnkey projects.

Thorough verification and customer acceptance test are carried out at the plant before shipment to ensure smooth startup at customers' shops.

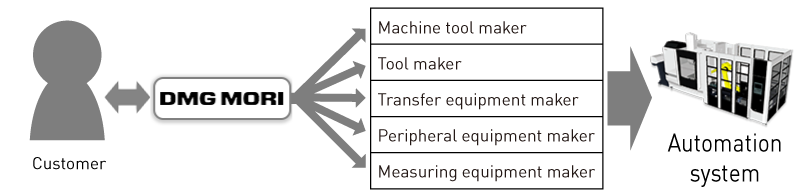

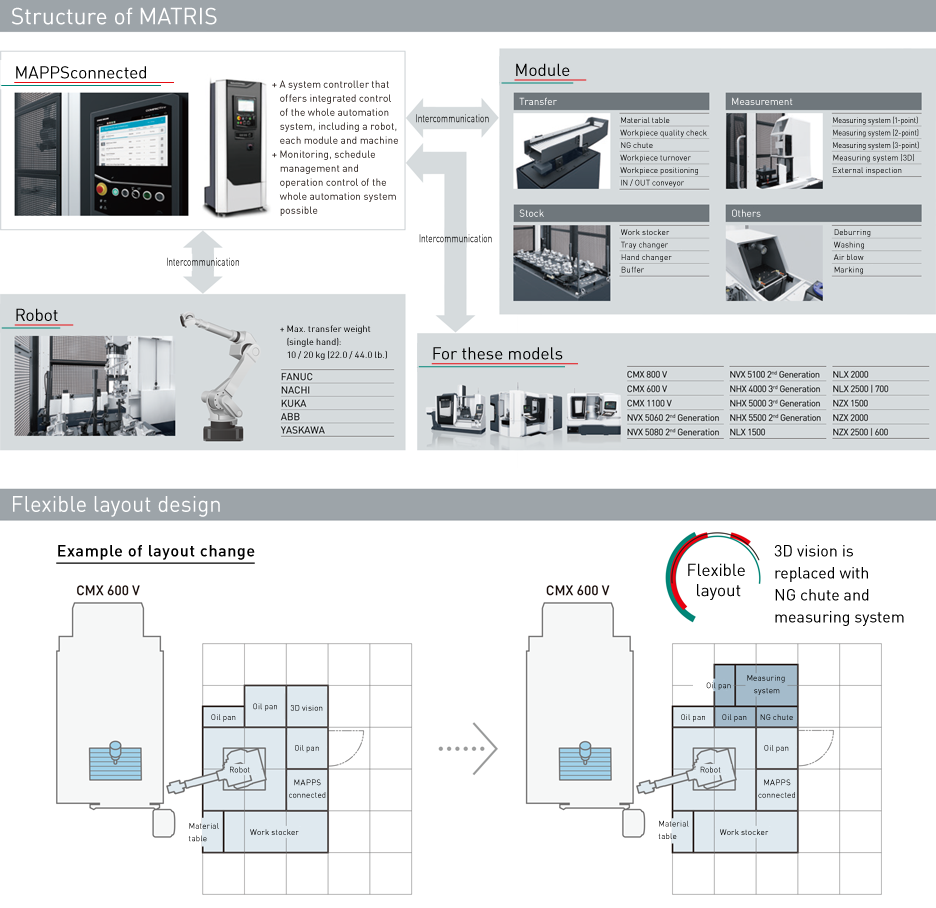

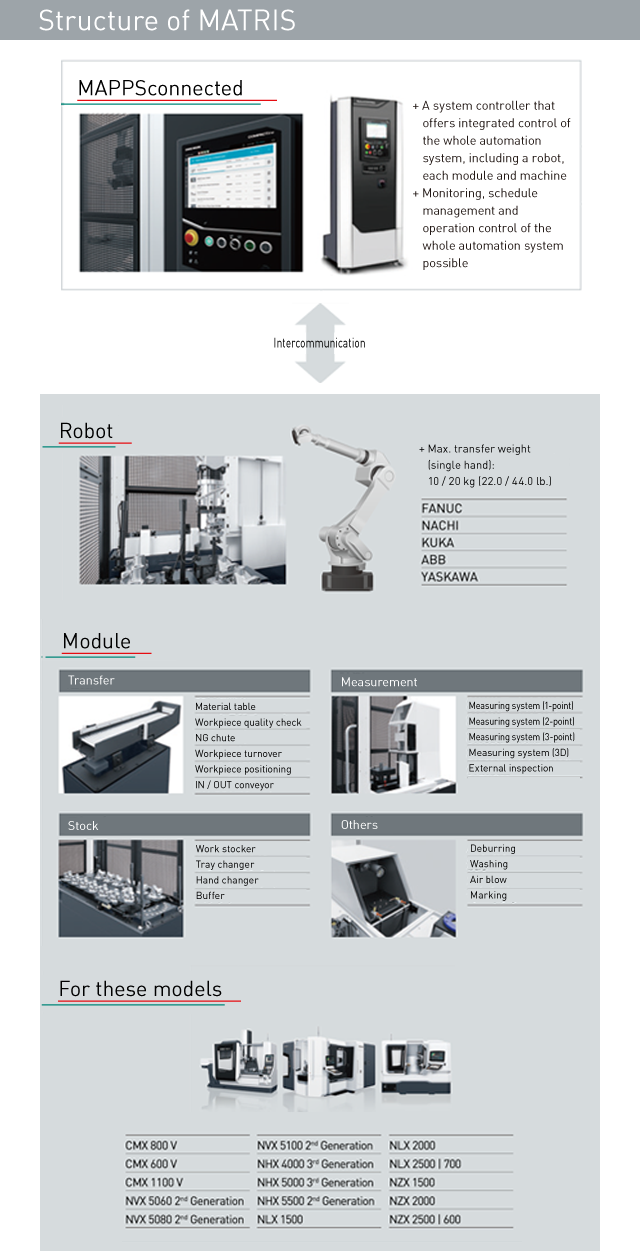

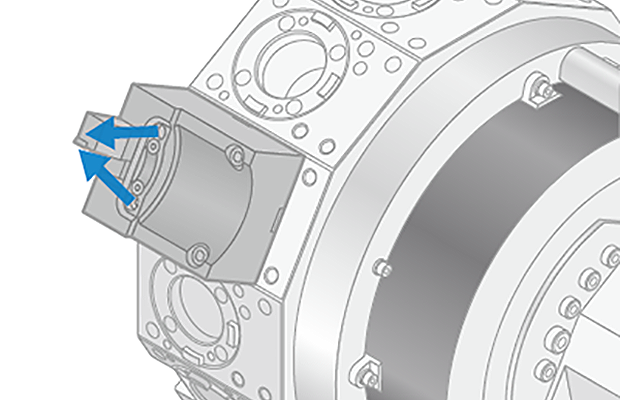

3. New robot system MATRIS

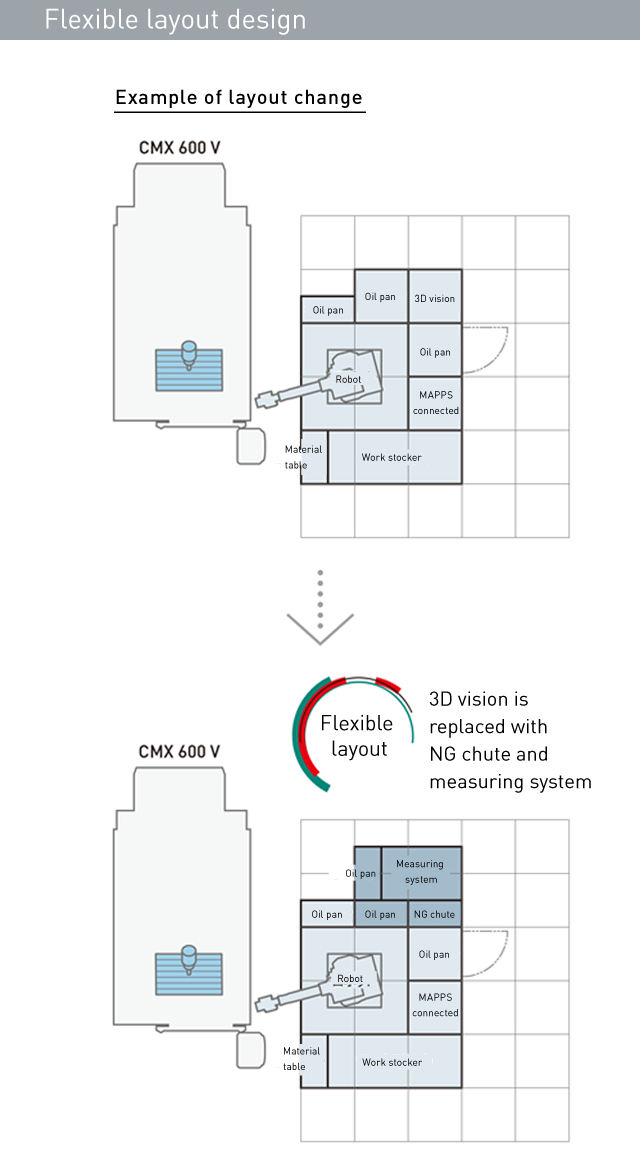

The MATRIS robot system comes with modularized peripherals to achieve faster system setup and flexible layout changes after installation.

4. Solutions to prevent system stop

Effective solutions for two major factors of abnormal system stop: "chips" and "coolant"

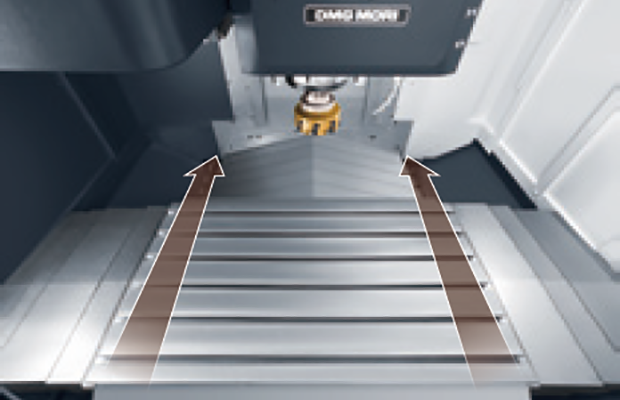

Chip disposal solution

-

Zero Sludge Coolant Tank

-

Inside the chip conveyor (spiral)

-

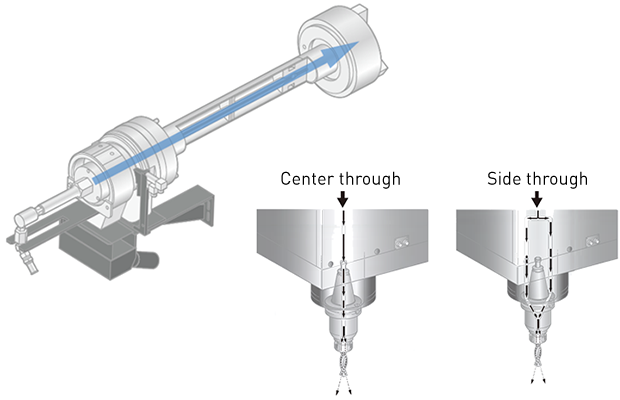

Through-spindle coolant system

-

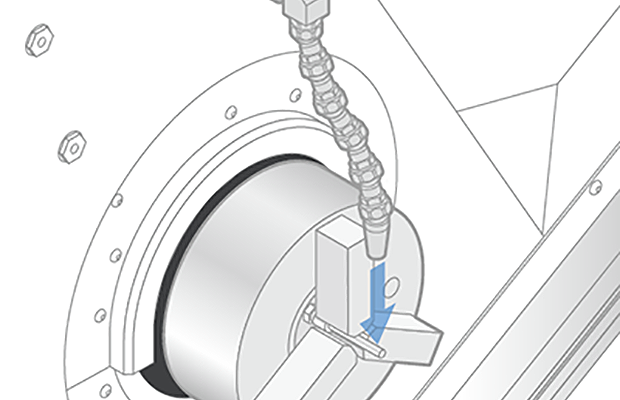

Coolant in upper part of chuck

-

Air blow (Tool tip)

-

Shower coolant

Coolant solution

-

・Elementless filter "FILSTAR"

An elementless filter for high-accuracy coolant filtration,

environment protection and cost reduction

Product information

-

・Oil skimmer "SLS Series"

A screw-type oil skimmer requiring no separation tank and

achieving significantly improved oil removal capability

Product information