- Products 2024/10/02 UP

-

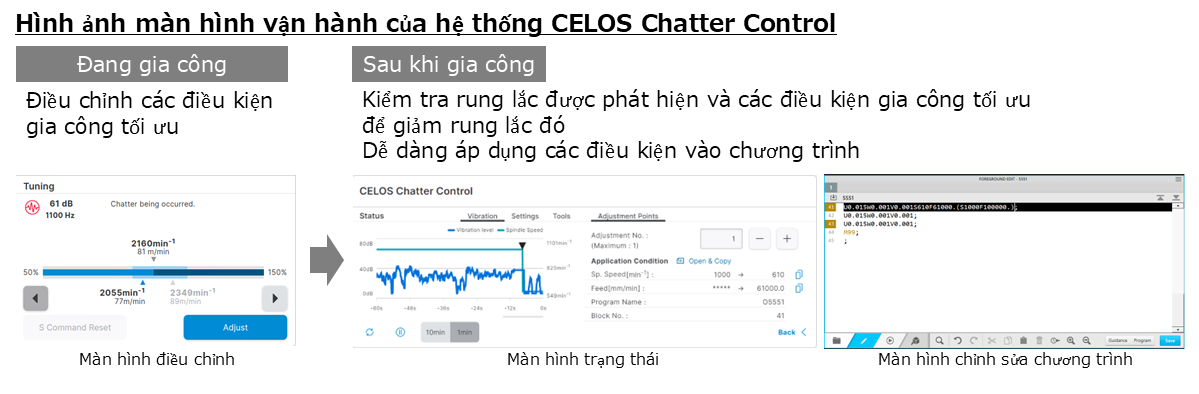

Kiểm soát rung lắc để có điều kiện gia công tối ưu

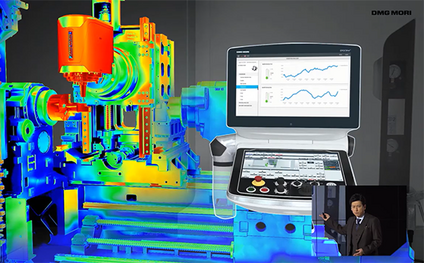

CELOS Chatter Control/MVC, một trong những chức năng “Giám sát” của Chu trình công nghệ, hỗ trợ gia công tối ưu bằng cách kiểm soát rung lắc. Cảm biến gia tốc gắn trên trục chính sẽ phát hiện rung lắc và phần mềm tích hợp do DMG MORI phát triển sẽ tính toán tốc độ trục chính để giảm độ rung lắc dựa trên tần số rung lắc và hiển thị một số điều kiện gia công trên màn hình.

Các kiểu máy áp dụng chính

CELOS Chatter Control

- Các dòng INH, NTX 500

MVC

- Các dòng NVX, NHX, NTX

Bối cảnh phát triển

Việc tìm ra điều kiện gia công tối ưu để kiểm soát rung lắc phụ thuộc rất nhiều vào kinh nghiệm của các kỹ sư lành nghề. Các kỹ sư ít kinh nghiệm hơn thường cần nhiều thời gian hơn do phải điều chỉnh theo phương pháp thử và sai. Việc sử dụng dao phay có hướng răng thay đổi và bước răng thay đổi có thể là một trong những giải pháp vì rung lắc ít có khả năng xảy ra với chúng, nhưng nhược điểm là chúng đắt tiền và có ít loại. Vì vậy, DMG MORI đã phát triển hệ thống “CELOS Chatter Control/MVC” có thể tự động tính toán điều kiện gia công có khả năng kiểm soát rung lắc.

Điểm bán hàng độc đáo

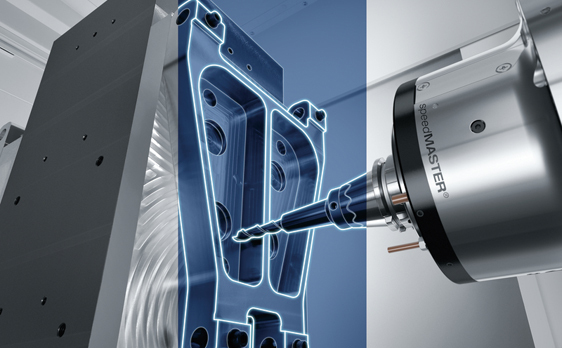

1. Trang bị cảm biến có độ chính xác cao

Các điều kiện xảy ra rung lắc rất đa dạng tùy thuộc vào vật liệu và hình dạng của phôi và loại công cụ sử dụng. Trong nhiều điều kiện khác nhau, CELOS Chatter Control/MVC phát hiện rung lắc bằng cách sử dụng cảm biến gia tốc có độ chính xác cao được gắn trên trục chính và tính toán các điều kiện gia công tối ưu. CELOS Chatter Control/MVC đặc biệt phù hợp với gia công sử dụng dao phay ngón và cũng rất hữu ích cho việc cải thiện điều kiện gia công trong các chương trình hiện có.

2. Khả năng vận hành

CELOS Chatter Control/MVC sử dụng giao diện đơn giản, thân thiện với người dùng và có thể vận hành thông qua bảng điều khiển màn hình cảm ứng. Chúng tự động phát hiện rung lắc và hiển thị tốc độ trục chính tối ưu để giảm rung lắc. Bằng các thao tác cảm ứng, người dùng có thể dễ dàng lựa chọn và điều chỉnh các điều kiện gia công tối ưu do CELOS Chatter Control/MVC chỉ định. Bất kỳ ai cũng có thể dễ dàng kiểm soát rung lắc ngay cả khi không có chuyên môn về giảm rung.

Các điều kiện gia công được điều chỉnh có thể dễ dàng được phản ánh trong các chương trình NC.

3. Năng suất cao

CELOS Chatter Control/MVC góp phần giảm thời gian gia công thử nghiệm và cải thiện thời gian vận hành máy vì nó nhanh chóng xác định các điều kiện gia công để giảm rung lắc bằng cảm biến gia tốc và phần mềm tích hợp do DMG MORI phát triển.