- Products 2022/05/23 UP

-

Support Programming for Steady Rest Operation

Steady rest for turret supports programming for operations of the steady rest attached to the turret. The programs can be easily created by the conversational programming method.

Main Applicable models

- NTX series

- CTX 4A series

- CTX TC 4A series

- SPRINT 50/65 series

Background of Development

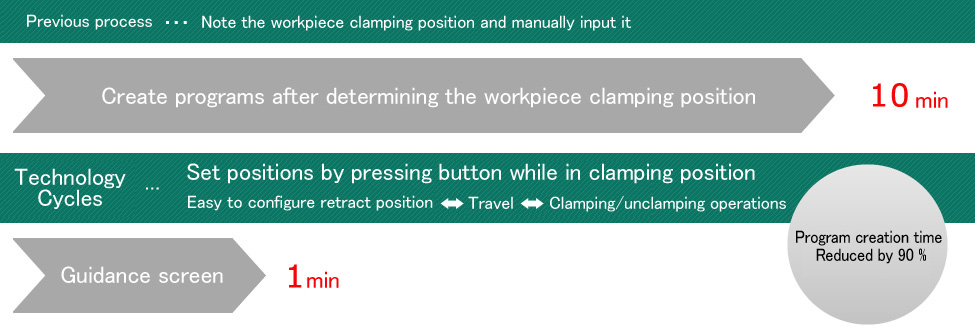

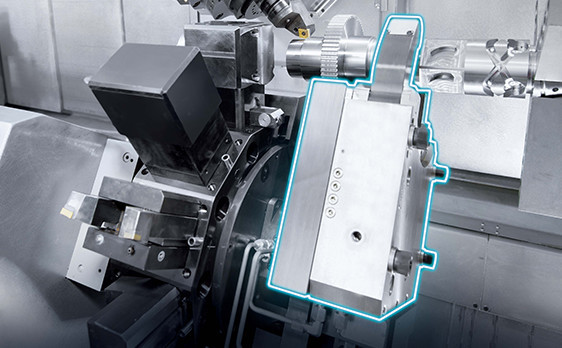

When machining long workpieces such as shafts, a steady rest is used to improve the machining accuracy. However, retracting and approaching operations need to be performed for the steady rest in order to prevent interference with the tools. To configure these operations, the operator must make a note of the workpiece clamping position in advance, and then create or manually input the program. To resolve this type of issue, DMG MORI developed Steady rest for turret that enables simple and quick programming for steady rest operations.

Unique Selling Points

1.Reduction in Programming Time

Steady rest for turret calculates the coordinates and the travel of the steady rest to set the retracting and approaching positions automatically, which can be done simply by pressing the setting button when the steady rest is at the clamping position.

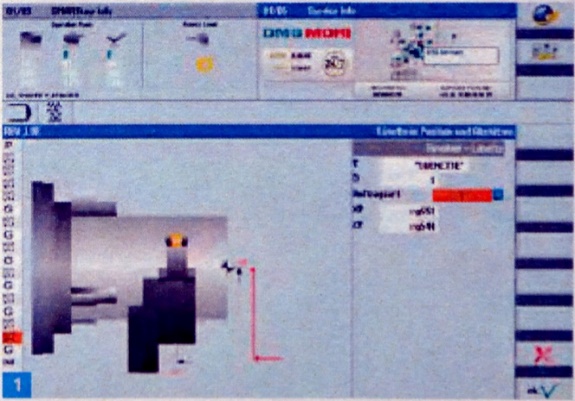

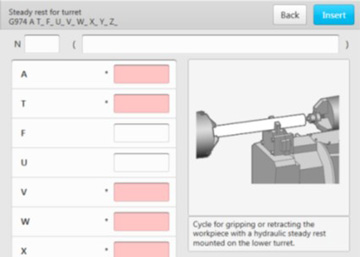

Operators can set parameters for approaching and retracting distances according to the guidance by the conversational programing method while checking the graphics displayed on CELOS, an HMI. Inputting parameters does not require any special skills. Conversational programming enables operators to create programs in a short time.

In the conventional way, the process from positioning of clamping to completion of programming used to take around 10 minutes, but with Steady rest for turret, it takes only some one minute. (According to DMG MORI study)

2.Solution with Steady Rest

DMG MORI offers solutions including the steady rest unit and software suitable for each customer’s workpiece through Open Innovation with peripheral equipment partners.

<SIEMENS>

<MAPPS>

Inputting of parameter by the conversational programming

Reduced programming time