- Products 2022/05/23 UP

-

Support Gear Machining with Hob Cutter

Gear Hobbing supports gear machining that uses a hob cutter on the NLX series models Y-axis specification (turning centers) and the CTX TC series models (integrated mill turn centers with a turn-mill spindle). As the gear machining programs can be easily made by the conversational programming method, the programming time is significantly reduced.

Main Applicable models

- NLX、ALX series(Y type)

- CTX TC/CTX TC 4A series

- NZX、NTX series

Background of Development

Gear machining with a hob cutter, in general, can be done in two ways: use a specialized hobbing machine, or mount a hobbing unit on a turning center or an integrated mill turn center. The former requires an investment in a hobbing machine and longer setup time because gears and shafts have to be cut in separate processes. The latter is effective in reducing setup time and increasing accuracy, although the program takes time to create because of its high complexity. Therefore, DMG MORI has developed Gear Hobbing that makes programming simple and quick for gear machining with a hob cutter on the DMG MORI turning centers and integrated mill turn centers.

Unique Selling Points

1.Conversational programming

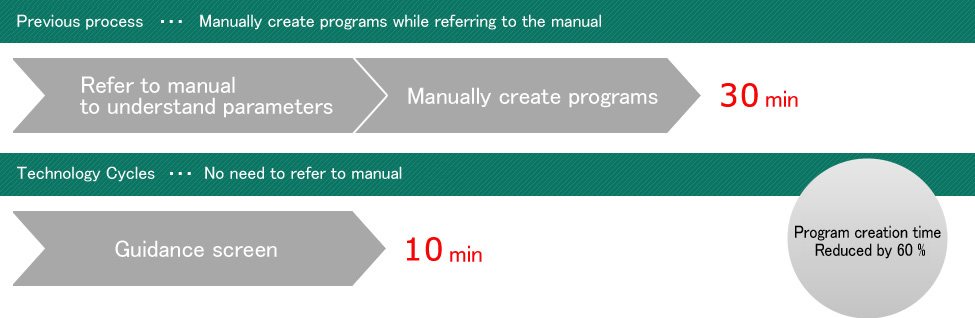

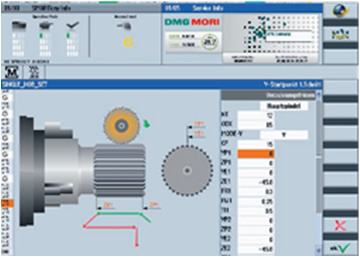

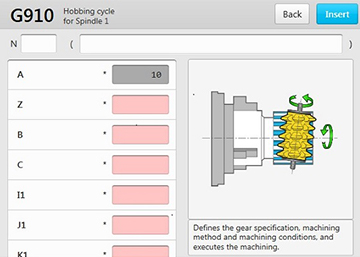

Operators can set parameters for information such as the number of teeth by the conversational programming method while checking the graphics displayed on the CELOS, a human-machine interface (HMI). Inputting parameters does not require special skills. As the programming is done interactively, the programs can be created in a shorter time. For instance, programming for Gear Hobbing, which used to take 30 minutes, can be done in some 10 minutes with Gear Hobbing according to the DMG MORI study.

2.Reduction in tool costs

Gear Hobbing enables operators to create programs that extend the life of hob cutters which are expensive tools. In gear machining with a hob cutter, only a certain portion of a tool is worn, making the tool life short. Therefore, positions of teeth need to be shifted manually during machining. With Gear Hobbing, it is possible to create programs that shift the position of a hob cutter inch by inch, so the effective tooth length can be uniformly used. This can extend tool life, contributing to cost reduction of tools.

3.High productivity

Gear Hobbing used on turning centers (Y-axis specification) or integrated mill turn centers can reduce the number of machines required because gears and shafts can be cut on one machine. The process integration eliminates setups and shortens an idle time to drastically improve productivity per unit area. What’s more, our Open Innovation partnership with peripheral equipment manufacturers makes it possible for us to offer holders optimal for gear machining, enabling customers to make the most of their machine abilities.

<SIEMENS>

<MAPPS>

Data input by the conversational programming method

Reduced programming time