- 고객 사례 예 2023/07/11 UP

-

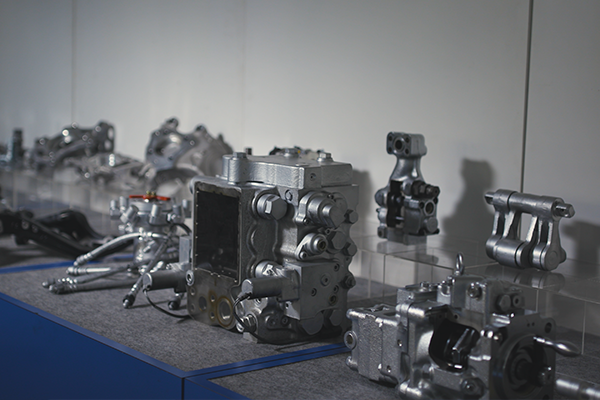

Founded in 1944 and headquartered in Sakaki, Nagano Prefecture, TSUZUKI MANUFACTURING is mainly engaged in parts manufacturing for the automotive and construction machinery industry. Through the application of unique production and precision machining technologies, the company has successfully combined high-volume and high-mix production under one roof. Today, TSUZUKI MANUFACTURING can handle large-scale orders from the automotive industry for several 10,000 pieces a month, while also providing hundreds of different workpiece types to the construction machinery industry. The complex production is supported by an efficient quality management system that covers the complete process chain from prototyping up to mass production. In anticipation of the growing EV industry, TSUZUKI MANUFACTURING has also developed innovative technologies such as "Radial Forging", a new forging method to produce light-weight hollow shafts.

While handling large-scale orders from the automotive industry for several 10,000 pieces a month and providing hundreds of different workpiece types to the construction machinery industry, the company successfully established an efficient quality management system that covers the complete process chain from prototyping up to mass production.

Automated workpiece transfer with WH-AMR enables operators to focus on more advanced tasks such as process management, leading to higher production efficiency.

This content is for members only