- 고객 사례 예 2023/07/11 UP

-

UTSUE SEIKI CO., LTD. was founded in 1951 in Hida Takayama. The company started as a general manufacturer of machine, camera, and motor parts and specialized on hydraulic parts around 1970. Today, the company supplies high-precision hydraulic parts to Japanese and overseas manufacturers of hydraulic equipment, construction machinery, and industrial machinery. The strength of UTSUE SEIKI is their efficient production system that allows them to perform machining, assembly and quality inspections under one roof. Dating back to the 1950s, UTSUE SEIKI has cultivated sophisticated technical knowhow and has also been a prominent user of high-precision machine tools. DMG MORI machines have played an essential role in their production since the 1980s, amounting to 150 machines in operation today. Only in the last three years, UTSUE SEIKI has invested in nine NHX 4000 3rd Generation horizontal machining centers to further increase its production capacity. “The various hydraulic valves, pumps, and motor parts that we produce need to fulfill very high standards in regard to roundness and cylindricity. We require micrometer-precision. The NHX 4000 with its 15,000 min-1 speedMASTER spindle enables fast and highly accurate machining. The compact pallet pool system CPP allows flexible machining of multiple workpiece types and has been highly useful for our high-mix low-volume production.”, says Mr. Nobuo Utsue, the president of UTSUE SEIKI.

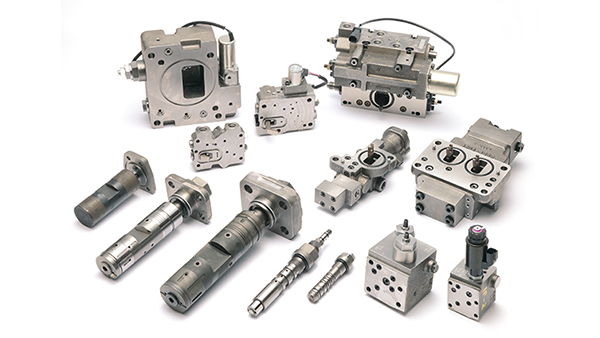

Lineup of high-precision hydraulic parts made by UTSUE SEIKI for Japanese and overseas manufacturers of hydraulic equipment, construction machinery, and industrial machinery.

UTSUE SEIKI UTILIZES THE NHX 4000 WITH CPP FOR QUICK AND PRECISE MACHINING OF HYDRAULIC PARTS THAT ARE SHIPPED WORLDWIDE.

UTSUE SEIKI utilizes the NHX 4000 in combination with the compact pallet pool system CPP to flexibly machine multiple products for their high-mix low-volume production.

(from left to right)

Shinsaku Kobayashi, Senior Managing Director and Factory Manager

Nobuo Utsue, President

Koichi Matsuba, Deputy Factory Manager

Masaaki Sakamoto, Senior Manager, 1st Manufacturing Department

UTSUE SEIKI CO., LTD.

“Hida no Takumi” is a well-known title to praise master craftsmen in Japan. UTSUE SEIKI is headquartered in Hida Takayama, the place of origin of the title where the spirit of excellent craftsmanship resides.

This content is for members only