- Products 2016/11/17 UP

-

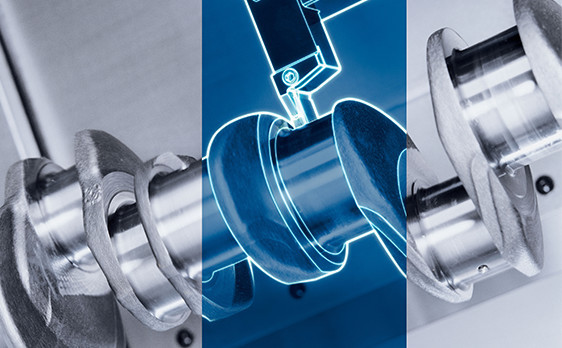

Support Programming for Excentric Machining

Excentric Machining supports the programming of eccentric machining. Parameters can be input by the conversational programming method, which ensures easy creation of complex machining programs of workpieces such as shafts with eccentric sections.

Main Applicable models

- NLX、ALX series(Y type)

- CTX、NTX series

- CTX TC/CTX TC 4A series

- DMU/DMC monoBLOCK series

- DMU/DNC FD duoBLOCK series

Background of Development

Mass production of crank shafts, which is a typical example of eccentric machining, mostly uses specialized machines. For a small lot production of sample products, in a conventional way, complex machining programs need to be created using CAM software, or machining should be done separately on a general-purpose turning center in such a way that an excentric section is chucked with the center set at the spindle center. Programming at a high level of difficulty and use of special chucks require steps of processes and a certain time.

Therefore, DMG MORI has developed Excentric Machining capable of excentric machining on the DMG MORI turning centers, 5-axis machines or integrated mill turn centers easily in a short time.

Unique Selling Point

1.Versatility

Excentric Machining is available on the NLX series Y-axis specification and CTX series (turning centers); the CTX TC series (integrated mill turn centers); and the DMU monoBLOCK series and DMU FD duoBlock series (5-axis machines), followed by more in the future.

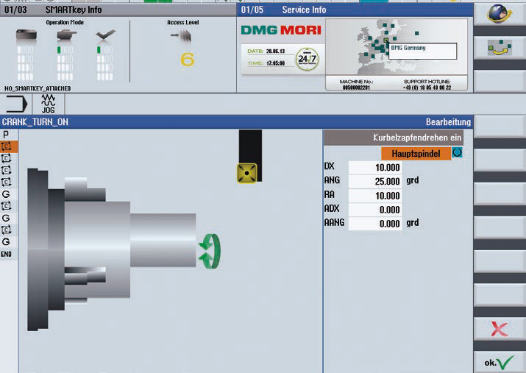

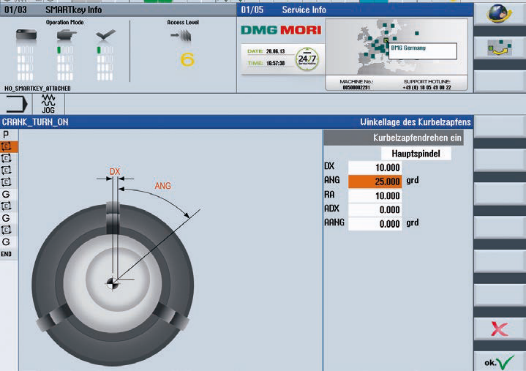

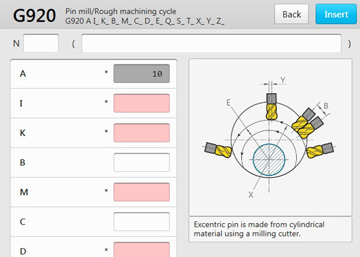

2.Conversational programming

Operators can set parameters for workpiece diameters, cutting width and excentric throw (distance between a rotation center of a workpiece and the center of the excentric cylinder) by the conversational programming method while checking the graphics displayed on CELOS, an HMI. Inputting parameters requires no special skill. As the programming is done interactively, the programming time can be drastically reduced.

3.High efficiency

Machining of an excentric section requires setups before and after a machining process. With Excentric Machining, on the other hand, a series of processes can be done on one machine, which ensures shorter setup time. Tools follow the profile of an excentric sections on the X- and Y-axis, and a whole workpiece can be seamlessly machined. As the technology cycle is available on integrated mill turn centers and 5-axis machines (turning table specification) and both turning tools and milling tools can be used, it achieves efficient excentric machining.

Excentric machining (turning)

Positioning in a workpiece

<SIEMENS>

Inputting parameters by the conversational programming method

<MAPPS>