- Peripherals

-

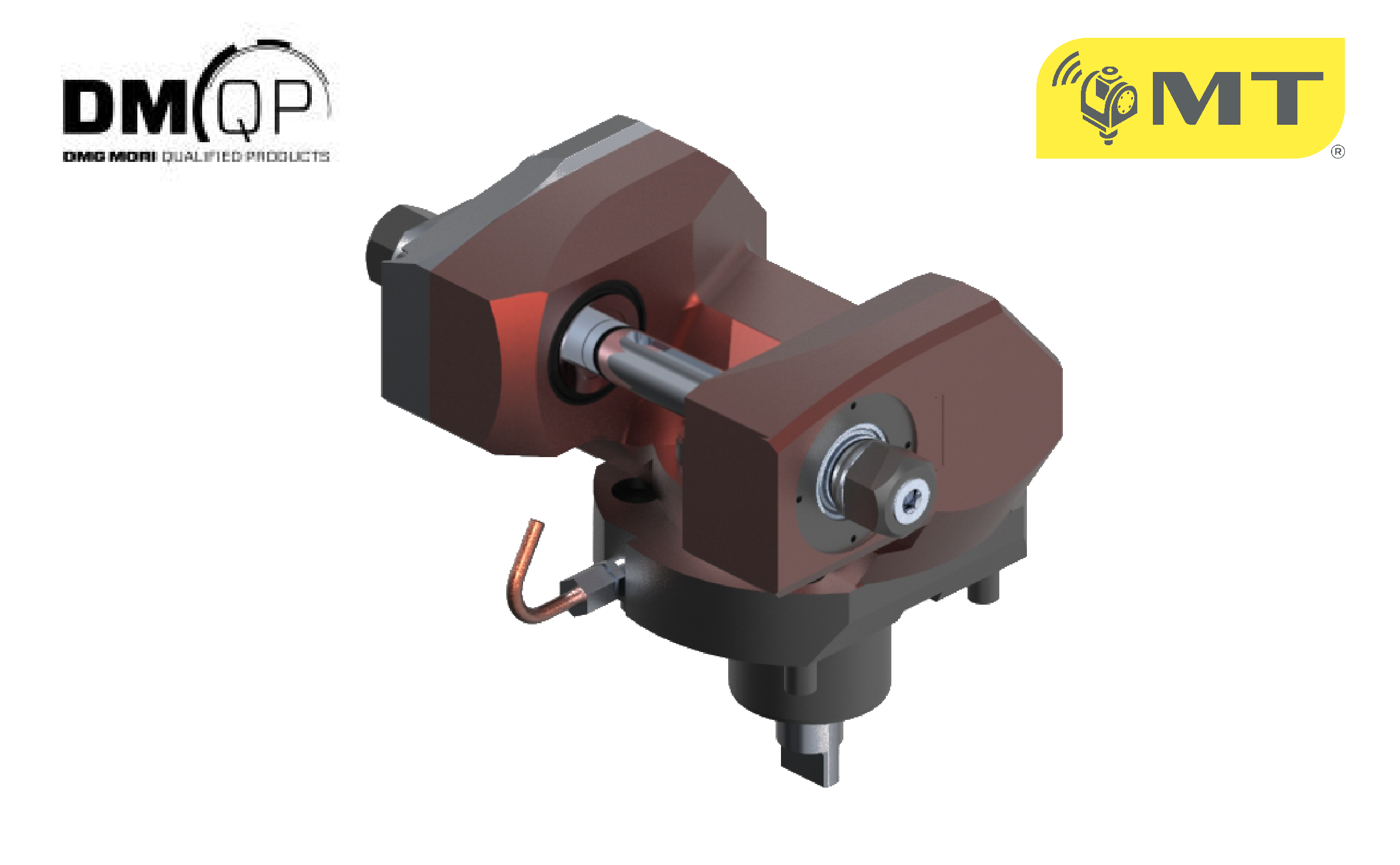

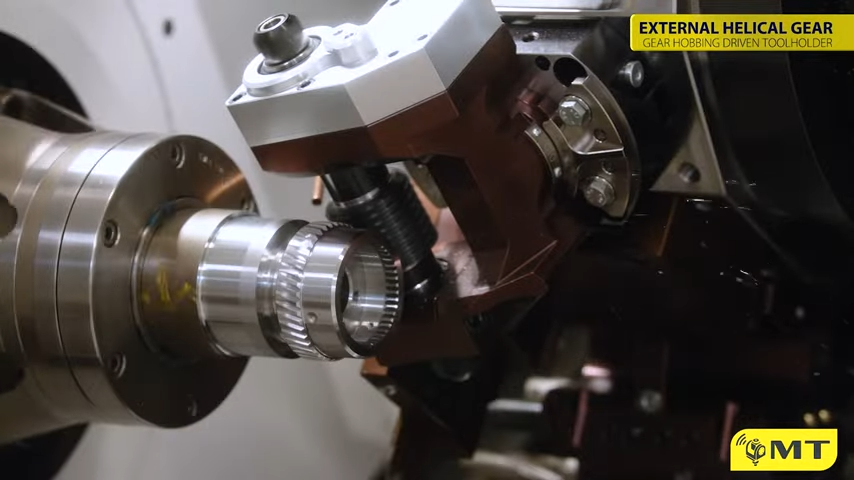

The driven gear hobber enables high-precision machining of external straight and helical gears on a Turning Center.

Toolholder for hob cutter for machining straight and helical gears. Uses powerful bearings for maximum cutting performance.

※For availability, please contact our sales representative.

※Manufacturer Name: M.T. S.r.l. (Italy)

Main Features

1. Gears machining unified on a single machine

By installing the driven gear hobber on a Turning Center, gears can be machined, thus reducing the setup times that would previously have required the use of two machines: a turning and a gear-hobbing.

2. Ability of high-precision machining of a wide range of gears

A variety of gears can be machined, such as cylindrical gears with straight or helical teeth and bevel gears with straight teeth. The angle can be adjusted for machining helical gears. Furthermore, high-precision gears can be machined thanks to the highly rigid support.

3. Simple tool change

The gear cutters used for machining gears, can be easily removed and installed without having to remove the driven gear hobber.

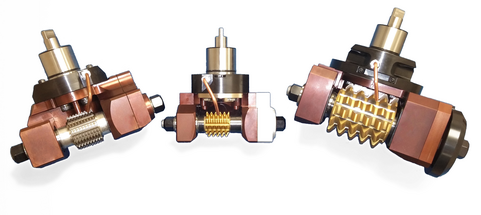

4. Wide range of line-ups

We offer a total of five sizes. Additionally, we also offer a very small, specialized unit for machining small-diameter gears on Swiss-type automatic turning.

- Light: Suitable gear cutter size 40D, 43L

- Standard: Suitable gear cutter size 50D, 50L

- Medium: Suitable gear cutter size 80D, 80L

- Strong: Suitable gear cutter size 80D, 80L

- Heavy Duty: Suitable gear cutter size 100D, 100L

Product Specification

※You can scroll to check

| Max. Rotation Speed | Torque | Ratio | Machine clamping | |

| MNL0411100 | 6,000 min-1 | 90 N•m | 1 : 1 | BMT-60(In our case) |

※For details, please contact our sales representative.