- 客戶案例範例 2020/01/23 UP

-

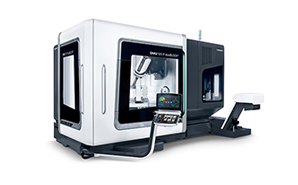

Mizuno Machinery, based in Toyama city, Toyama, has been challenging machining of a high degree of difficulty by use of multiple simultaneous 5-axis control machining centers. Their specialty is highly accurate machining of aluminum parts for semi-conductor production equipment.

Their former company name is Mizuno Ironworks. As the name indicates, the company once specialized in turning on lathes, providing round components for machine makers in Toyama Prefecture. Then why did they shift their business to aluminum machining? The key is “fun of doing the work.”

About 20 years ago, Mizuno Machinery decided to introduce a machining center to begin machining of square workpieces, and it was aluminum. The ratio of the new business rose every year, and finally outnumbered that of their original business.

The company now specializes only in aluminum machining. “Turning is for mass production. So what’s demanded is mainly cost reduction, and it’s not fun.”

We don’t mass produce aluminum products, but we can make something interesting. What’s important to me is whether we can do it with fun. That’s my standard. I want my staff to get stimulated, not get bored.” President Fumimasa Mizuno explains the reason for the company’s business shift.

This content is for members only