- Products 2017/01/27 UP

-

Monitor Load on Tools During Machining

Easy Tool Monitoring, one of the “Monitoring” functions of Technology Cycles, monitors the tool load during machining and detects the tool breakage and wear. It monitors the current value of the spindle in real time and issues a tool change alarm, which can prevent machine failure as well.

Main Applicable models

- NLX、NZX、NVX、NHX、NTX series

- ALX、CMX series

- DMU 50(FANUC)

- CTX TC / TC 4A series

- CTV series

- SPRINT 50、SPRINT 65 series

Unique selling points

1.Preventive maintenance

Unlike the tool life management functions installed in many of the NC machine tools, Easy Tool Monitoring monitors the state of the tool in real time. When a current higher than the set value is detected, the tool is determined to be damaged or excessively worn, and a tool change alarm is issued. It is also possible to stop the spindle automatically by setting a current value that is one level higher. In this way, this function prevents accuracy deterioration caused by worn or damaged tools and failure of the machine due to overload.

2.Reduction in tool cost

Easy Tool Monitoring makes it possible to change the tool in accordance with its state because the wear and breakage of the tool is detected directly, not by counting the number of uses or the cutting time. This function is useful in the high-mix, low volume production and prototyping as well as mass production.

3.Operability

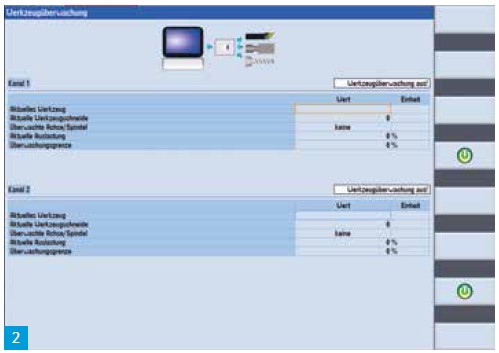

Settings can be easily done by entering current values in the setting screen on CELOS. Operators can set two levels of current values, one for issuing an alarm and the other for emergency stop, based on a reference value obtained during the normal condition of a test machining.

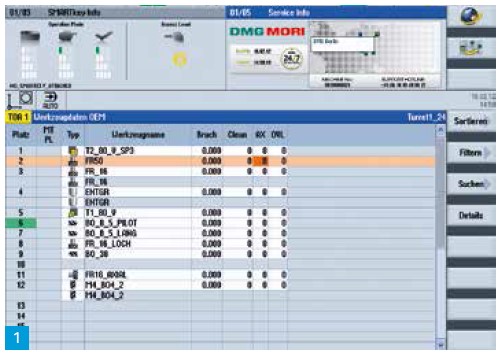

Tool management system

Current value setting screen