- 고객 사례 예 2024/04/05 UP

-

KUSUDA chose the new INH 63 to increase productivity, increase workplace motivation, and improve the atmosphere at the factory.

Founded in 1920, KUSUDA Co., Ltd. has been in operation for more than 100 years. The company focused entirely on casting until the 1980s, when it began machining in order to increase added value. The company built a unique system capable of handling everything from casting and machining to sending machined goods directly to customer factories, and underwent significant growth. The company continues to create machine tool parts and other high-quality casting products, and to contribute to the development of the manufacturing industry, with its superior technology and spirit of "harmony and innovation." The company is also a DMG MORI supplier, and has supplied many parts for spindle housings and flanges since DMG MORI was founded in 1948.

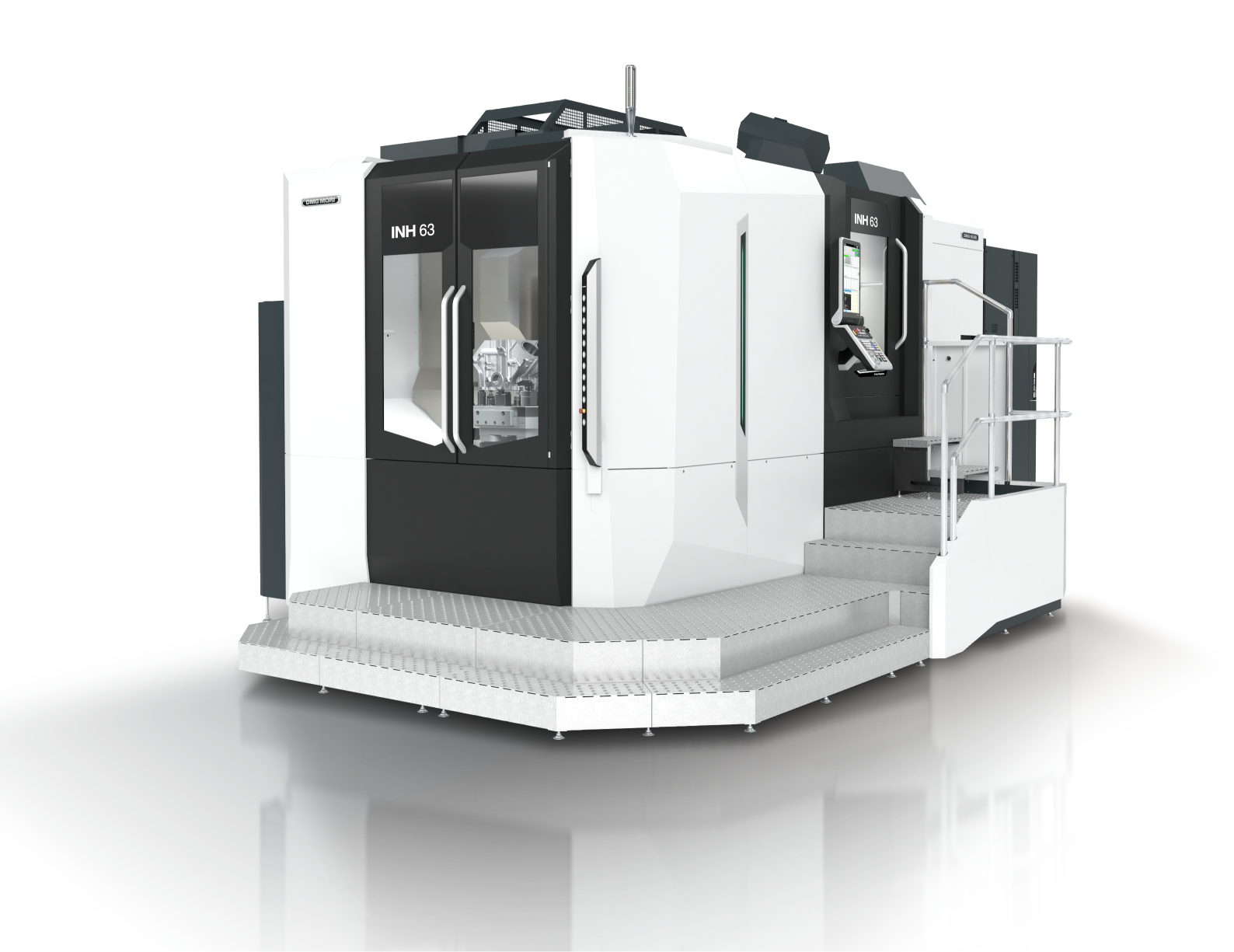

KUSUDA first began using DMG MORI products in the 1980s, and currently operates around 40 such machines. The company is constantly updating its equipment to meet the needs of its customers. In the 2010s, the company chose a DMU 50 5-axis machine and an NLX 2500 equipped with a touchscreen operation panel and CELOS. In 2023, it had its first INH 63 5-axis control horizontal machining center installed.

INH 63 and CPP made it possible to combine and automate processes, increasing productivity

Processes were combined to reduce setup frequency

This has taken productivity and operator safety to the next level

KUSUDA handles everything from casting to machining internally, and its high-mix low-volume production system is capable of producing products up to the 200 kg weight class. Although setup on their previous 3-axis machine and 4-axis horizontal machining center required some time, INH 63 allowed the company to combine processes, reducing setup frequency. Kentaro Yamanaka, who works in the Machining Department, noticed the difference himself. "Setup can take up to 30 minutes, so reducing how often we need to do it has really made work quicker."

According to Kiyoto Kusuda, manager of the Sales Department, "Setup can be dangerous when handling large or heavy workpieces. Eliminating even a single dangerous task by combining processes can help to keep our coworkers safe." INH 63 is standard equipped with a powerful spindle with a maximum spindle torque of 808 N⋅m and spindle output of 85/40 kW (10%ED/continuous), making it suitable for everything from heavy cutting to high-speed cutting. KUSUDA reports that the machining center has increased productivity thanks to the higher basic machining speed.

INH 63

Fully equipped with proprietary technologies aimed at eliminating downtime

- Combine processes to reduce setup work

- Improve productivity and operator safety

- zero-sludge COOLANT pro significantly reduces coolant tank cleaning work

- Highly accurate and durable all-axis twin ball screw and slant column structure

- powerMASTER spindle handles everything from heavy cutting to high-speed cutting

- Combine and automate processes to save energy and achieve sustainable production

INH 63 / INH 80の紹介動画

Casting process where metal is melted at temperatures exceeding 1,000°C and poured

Using ERGOline X with CELOS X operation panel to perform machining setup

A wide range of parts produced through high-mix low-volume production

CPP, the pallet transfer system that brings high machine uptime to high-mix low-volume production

The blank workpieces cast and machined internally at KUSUDA have roughly the same shape whether blank or a finished product. There are fewer areas to machine compared with a product carved from a blank workpiece block, and the cycle time tends to be shorter. Many pallets are therefore required to increase uptime during unsupervised operation at night. INH 63 can be connected to an 8-surface CPP (compact pallet pool system) to increase uptime. "We found that we could only fit a 6-surface CPP in our installation space. However, DMG MORI delivered a special design that allowed us to fit an 8-surface CPP," recalls Mr. Kusuda. The company also chose "CELOS Chatter Control," a technology cycle that can automatically switch to optimal cutting conditions. "No chatter marks are left on the machining surfaces of the finished products, which helps to reduce workloads and increase productivity. The tool management system also lets us machine safely without wasting tools. If a tool breaks at night, the system detects the broken tool and prevents an accident from happening," explains Mr. Kusuda.

The perfect solution for chips, coolant, and mist

Helps to improve workplace environments

INH 63 uses the new zero-sludge COOLANT pro, an innovative vertical coolant tank that is more advanced than previous zero-sludge coolant tanks. High-performance chip washing prevents chips from accumulation in the machine, helping to keep unsupervised operation running continuously for longer. Mr. Kusuda expects the tank to reduce time spent on cleaning. "We mainly cast FC material, and sludge quickly accumulates in the coolant tank. Cleaning this used to take three workers an entire day two or three times a year, but we expect the new tank to mostly eliminate major cleaning work." The machining center also uses zero FOG, a built-in mist collector that traps at least 99.97% of fine particles 0.3 μm in size, to help prevent mist-related trouble. According to Mr. Yamanaka, "zero FOG has eliminated mist from within the machine, for truly excellent visibility. We can machine without being concerned about cutting conditions, and this has really increase productivity." Mr. Kusuda agrees. "Our work environment is cleaner, which keeps our operators healthier."

Our Machining Division is even better thanks to INH 63. We now aim to attract more business with a focus on our production system, which can handle everything from casting to machining.

KUSUDA Co., Ltd.

Sales Department Manager

Kiyoto Kusuda

Actively introducing the latest technology and equipment for further growth and sustainable production

KUSUDA had initially considered choosing an NHX 6300 2nd Generation 4-axis horizontal machining center to replace its original MH-63 4-axis horizontal machining center. However, the company immediately decided to go with the new INH 63 after reading the INH 63 product literature. Yoshinori Kusuda, president of KUSUDA, explained why. "Our management philosophy at KUSUDA is 'growing with our customers with the latest technology, equipment, and service to keep our customer happy.' Switching to INH 63 is another example of putting our philosophy into action. Our greatest strength is our unique ability to handle everything from casting to machining internally. We chose INH 63 because it allows us to combine processes and machine products with a high level of speed and accuracy, and we thought it would help us attract more business by focusing on this strength. Its excellent energy-saving performance made it the ideal choice to help us achieve sustainable production and a carbon neutral society."

Another factor in choosing INH 63 was the excellent design focused on the details. "INH 63 has a double-sided structure that's extremely durable, even for a single table. You can really feel the innovation in the details, such as the basic structure and chip processing performance. The design is also extremely stylish, which has really helped to motivate our operators," explains Mr. Kusuda with a smile.

Note: Organization names and titles are current as of publication timing.

This content is for members only