- 고객 사례 예 2018/05/21 UP

-

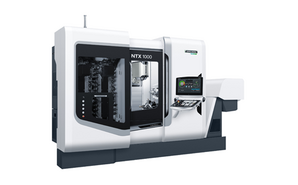

Yuki precision changed its business model from low-mix high-volume to high-mix low-volume production to adapt itself for the aerospace industry, and has been growing ever since. This company, which is well trusted by JAXA and other prominent aerospace industries, uses DMG MORI’s mill-turn center NTX 1000 2nd Generation (hereinafter referred to as NTX1000).

Most-skilled engineer in charge of NTX 1000

The company always holds high expectations when introducing a new machine. NTX 1000 met the company’s high standards and receives favorable comments by Mr. Masahiro Ueno, General Manager of Manufacturing Department: “I immediately liked the high rigidity. The solid mechanical structure eliminates issues over the spindle runout. It helps us fully utilize specialized cutting tools and achieve top-level precision and performance.”

The company’s high expectation in NTX 1000 is shown in the fact that the company’s ace operator of mill-turn centers, Mr. Taizo Yagi, was assigned to be the machine’s exclusive operator. Mr. Yagi explained the high operability as follows; “I operated a 5-axis machine for the first time. However, it was easier than expected, because of the optimized design for interference prevention and easy tool change. The high rigidity enables cutting at higher speed, which leads to shorter lead time than other machines. It was also a first experience to use an operational panel with a touch panel, but the CELOS’s intuitive and user-friendly interface helps a lot.”

Aim for better technology with the new laboratory

This content is for members only