Additive manufacturing

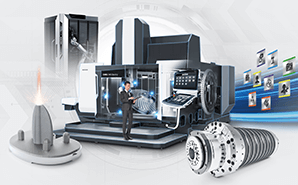

Additive manufacturing is a cutting-edge technology that produces 3D forms by metal deposition, enabling repair of worn workpieces and machining of complex-shaped workpieces to which tools are physically difficult to be applied. DMG MORI provides two machine tools that adapt different technologies ahead of the world: powder nozzle and powder bed methods.

What's Additive manufacturing?

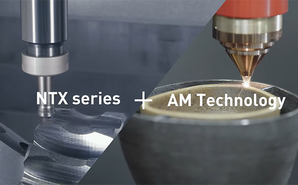

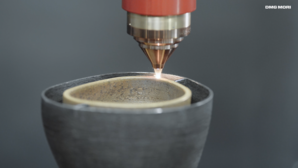

Powder nozzle method

In the powder nozzle method, metal powder is supplied from the nozzle, and laser is irradiated to the deposited powder to melt and sinter it.

The advantage of the method is that molding can be done in a short time because lamination and melting are done at the same time. This is suitable to lamination of different kinds of metal powder materials, and repair of complex-shaped and high value-added products such as impellers and blades.

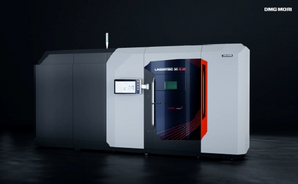

Powder bed method

In the powder bed method, powder materials are deposited layer by layer, followed by laser irradiation to the deposited powder to melt the specified areas.

The method realizes precise forming and is suited for products and parts with a one-mold structure, and those manufactured from scratch. The machine has a small number of axes and simple structure, allowing space-saving machine design.

-

Video

NEW

2025/06/12

LASERTEC 30 SLM US - Next generation SLM machine -

- 0 View

- 0

-

Video

2024/08/02

3D Part Scanning Directly Inside the Machine – scan3D for Quick Repair Processes

- 0 View

- 0

-

Video

2024/07/31

Additive Manufacturing Reinvented With the New LASERTEC 30 SLM 3rd Generation

- 0 View

- 0

-

Berita/topik

2023/09/27

LASERTEC 30 SLM meets Solar Cars! DMG MORI AM parts used in 3,000-km race

- 1012 View

- 0

-

Video

2023/03/13

Selective Laser Melting : Comprehensive process chain with NX

- 294 View

- 0

-

Video

2021/12/20

Road to Front Runner Vol.34「KOMINE Products Co., Ltd.」 Challenging New Fields with Additive Manufacturing x 5-axis Machining

- 228 View

- 0

-

Video

2021/09/30

Laser Metal Additive Manufacturing machine "LASERTEC 3000 DED hybrid"

- 1134 View

- 0

-

Video

2021/06/03

DMG MORI TVCM「Front Runner Vol.34 KOMINE Products Co., Ltd.」

- 855 View

- 0

-

Video

2020/12/25

LASERTEC Precision Tool

- 224 View

- 0

-

Video

2020/06/26

LASERTEC 3D hybrid / Introduction video

- 205 View

- 0

-

Materi seminar

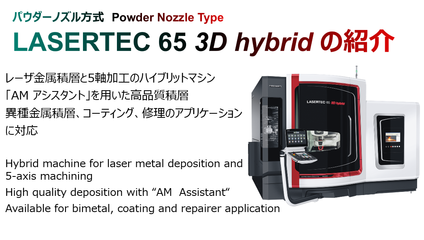

2020/02/13

TCT Japan 2020

「Introduction of LASERTEC 65 3D hybrid」- 193 View

- 0

-

Video

2020/02/03

LASERTEC SLM Series CG Animation

- 105 View

- 0