Features of DMG MORI

5-axis Machines

(5-axis Control Machining Centers)

With outstanding sales record,

DMG MORI helps you find the best machine tool

Reason why DMG MORI can provide the "best machine"

-

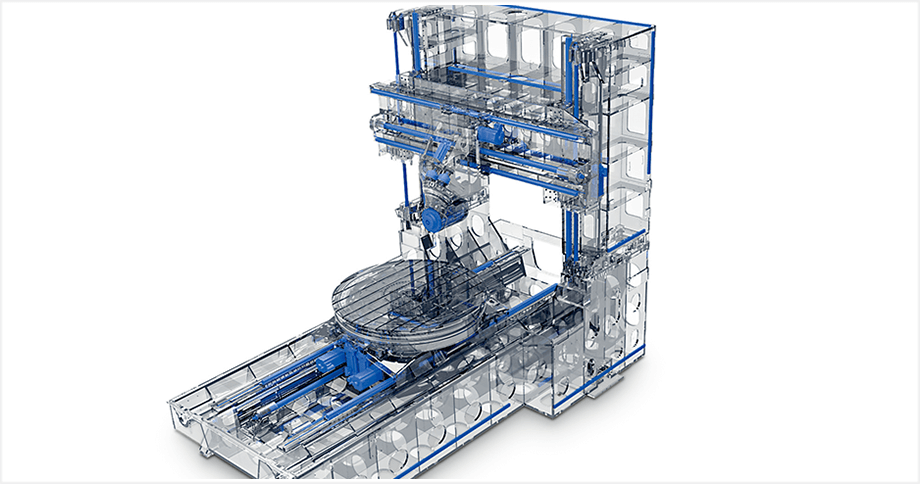

Extensive product lineup & modular design

Allow for prompt, reliable response to customer requests and concerns over introduction of 5-axis control machines- View more details

-

5-axis control machining specialists with a wealth of expertise and knowledge

Offer appropriate advice on everything from how to choose specifications to how to bring out the best in the machine- View more details

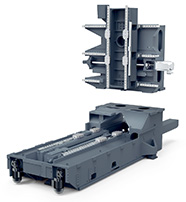

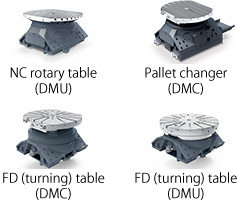

Extensive lineup & modular design

Extensive lineup covering all three types of 5-axis control machines

Simply combine modules according to your needs

Example of modules (duoBLOCK series)

-

- Machine basic structure

-

- Control unit

-

- Spindle

-

- Tool magazine

-

- Table

-

- Automation

5-axis control machining specialists with a wealth of expertise and knowledge

- Domestic area sales managers: Approx. 100

- Application engineers: Approx. 200

- Members of the 5-axis machining task force,

“5-axis Competence Center”: Approx. 25

Engineers with ample experience support everything

from machine selection to startup and training

Delivery record of over 30,000 units

DMG MORI’s 5-axis control machines incorporate advanced and precise 5-axis technologies. We have delivered more than 30,000 machine tools over the past decade and responded the needs of customers in various fields.

Respond to the needs of various fields

-

Aircraft

-

Medical equipment

-

Automobiles

-

Energy

-

Boats & Ships

-

Die and mold

5-axis control machining task force

“5-axis Competence Center”

Organization outline

Satoshi Kaji

Center manager

5-axis Competence Center

Test cut on DMG MORI’s cutting-edge 5-axis control machines possible

Other features of DMG MORI

5-axis control machines

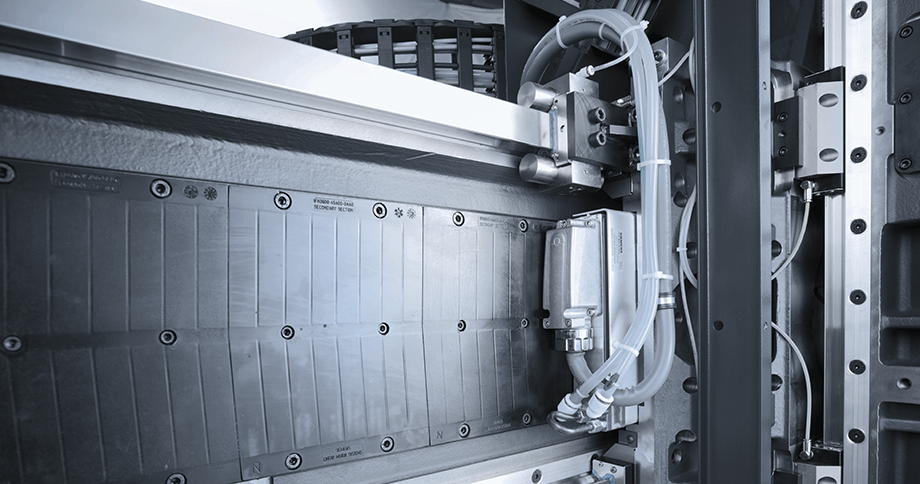

High speed & high accuracy with DMG MORI’s unique structure

-

3-point support for easy leveling

Long-term, stable machining accuracy

The structure ensures swift production startup and minimizes accuracy loss caused by gradual changes in floor conditions over the years.

It is an ideal choice for those who wish to start production as soon as possible or use the machine as long as possible.

(excluding some models) -

Linear motors to achieve high speed

and high accuracy with no backlash

A perfect choice for those seeking even higher accuracy and speed.

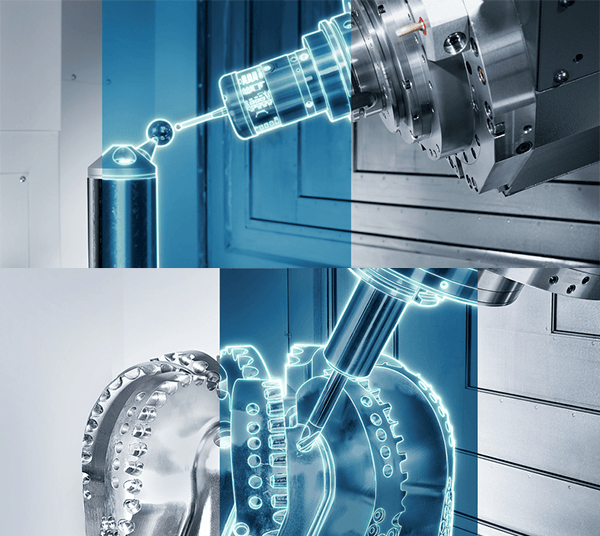

A wide variety of operation support

-

CELOS X for intuitive operation

With various CELOS X APPs, extensive conversational programming menu and intuitive operation by a touch panel, CELOS X makes machine operation easy, even for beginners

-

DMG MORI's exclusive operation

support solutionsDMG MORI Technology Cycles include a wide range of measurement and error compensation solutions

-

Substantial training even

after machine purchaseYou can learn everything from programming, machine operation to inclined surface cutting through classroom lectures and hands-on training