- Products 2023/08/23 UP

-

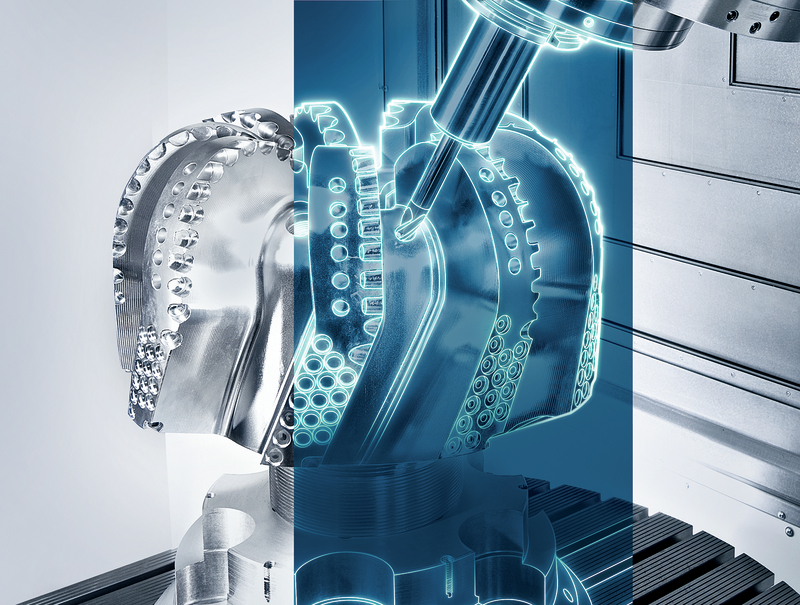

Adjust Smoothness of Look-ahead Interpolation

Application Tuning Cycle, one of the “Shaping” functions of Technology Cycles, adjusts the smoothness of look-ahead interpolation. Operators can set the optimum cutting method simply by selecting either the time priority mode or accuracy priority mode according to machining surfaces.

Main Applicable models

- NVX、NHX、NTX series

- CMX series

- DMU 50(FANUC)

- DMU / DMC monoBLOCK series

- DMU / DMC(FD)duoBLOCK series

- DMU eVo series

Unique selling points

1.Reducing machining time

Cutter paths on a curved surface are composed of sequences of small points, and cutting programs are created in such a way as to look ahead the cutting trajectory and move the cutter from point to point. When priority is given to time, workpiece corners can be machined smoothly with the machining speed prioritized. When priority is given to accuracy, high-precision contouring is done at low speeds with a focus on specified points.

For machining that requires contour accuracy, such as cutting of sides, pockets, and die and mold, roughing is done at high speeds with less accuracy, whereas finishing is performed at low speeds with high accuracy. As a result, machining time as a whole can be reduced.

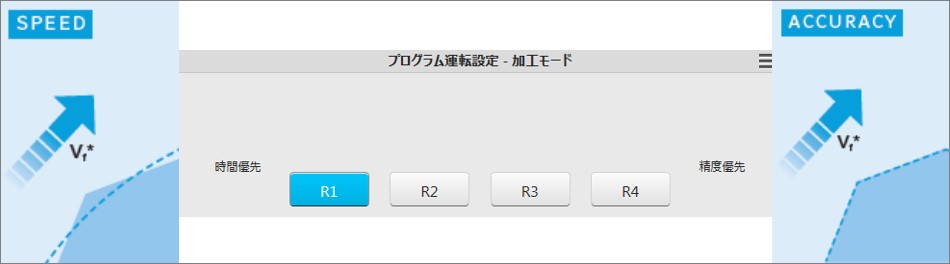

2.Easy setting in one-touch operation

Operators can set the optimum cutting method according to the workpiece simply by selecting one of the four machining modes on the Application Tuning Cycle setting screen of CELOS. Thanks to the one-touch operation, no special programming knowledge is necessary.

Screen for Setting Cutting Mode

3.Embedding to Machining Programs

Application Tuning Cycle can be embedded in machining programs. According to the surfaces to be machined, the cutting mode can be switched, for example, from the speed priority mode to the accuracy priority mode, during machining. Operators can set the programs simply by inputting parameters with no special knowledge.