Understanding Carbon Neutrality

SDGs, decarbonization, and related initiatives have gained frequent attention in the news. While some may assume these efforts are exclusive to large corporations, they are actually affecting all of us and businesses as well. Conversely, taking action now may offer a substantial competitive advantage in the future. Here is why we need to decarbonize and how we can do it.

Becoming aware of decarbonization

In recent years, the social expectations for companies to fulfill their environmental responsibilities, particularly in decarbonization and CO2 reduction, have grown significantly. Many companies are actively addressing environmental issues, and some are even incorporating decarbonization as a key objective in their business strategies.

Global discussions on coordinated CO2 reduction efforts have been ongoing, with a significant shift following China's announcement of its decarbonization target for 2060 at the UN General Assembly in 2020. This, along with earlier commitments from Europe, marked a substantial change in the global trajectory.

While the United States, Europe, and Japan have set decarbonization targets for 2050, China's announcement unifies efforts among these major contributors, representing around 60% of global CO2 emissions. This alignment toward a decarbonized society holds significant potential to drive innovation and demand.

Governments worldwide are increasingly committing to decarbonization, reshaping expectations for companies to achieve this goal by 2050. Moving forward, decarbonization efforts will not be exclusive to major or advanced companies but will become a standard expectation for all businesses.

Why machine tool users must reduce CO2 emissions

At manufacturing sites, the use of fuel and electricity for equipment and air conditioning results in CO2 emissions. Companies are increasingly requiring suppliers to minimize CO2 emissions from their processes. SBT*, a leading global certification program, demands reductions not only in a company's direct emissions but also in the overall emissions linked to its business activities.

*SBT (Science Based Targets):

Greenhouse gas emission reduction targets set by companies for the upcoming 5 to 15 years. Aligned with the Paris Agreement, the targets aim to restrict the global temperature increase to well below 2°C (Well Below 2°C/WB2°C), representing the maximum 2°C below the pre-industrial age, and further aspire to limit it to 1.5°C.

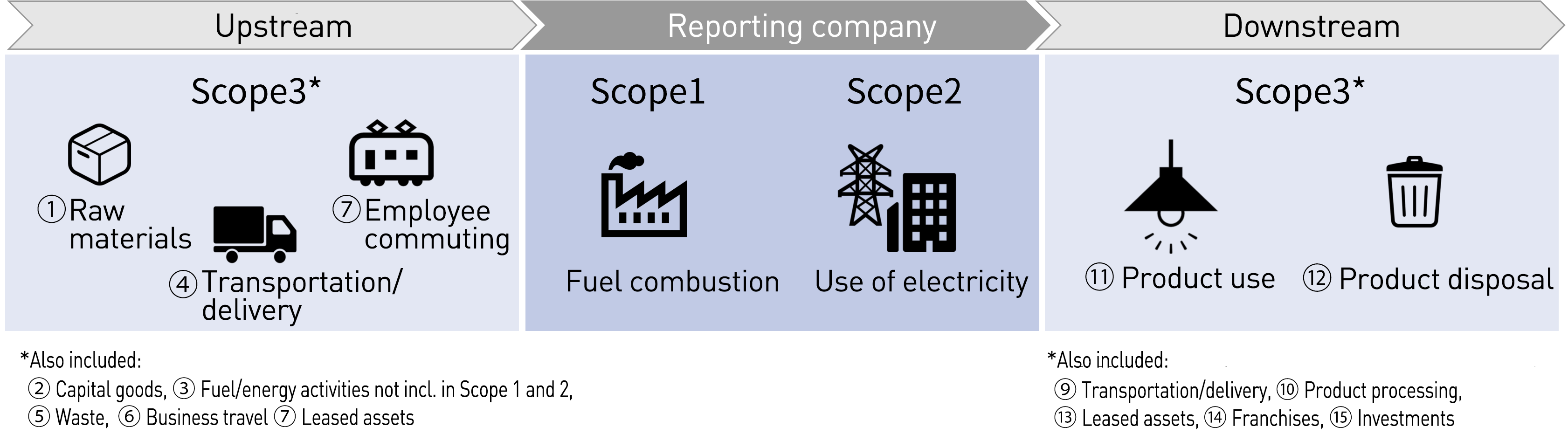

Supply chain emissions as defined by SBT

Scope1: Direct greenhouse gas emissions by businesses themselves(Fuel combustion, Industrial processes)

Scope2: Indirect emissions from the use of electricity, heat and steam supplied by other companies

Scope3: Indirect emissions other than Scope 1 and Scope 2(Emissions of other companies related to the activities of the business)

*Numbers are Scope 3 categories

Source: Ministry of the Environment, "SBT Detailed Material (as September 30, 2023)"

Some SBT-certified companies request that their suppliers, from whom they procure raw materials and parts, set targets.

List of SBT-certified companies that request suppliers to set targets to reduce Scope 3 emissions

Source: Ministry of the Environment, "SBT Detailed Material (as September 30, 2023)"

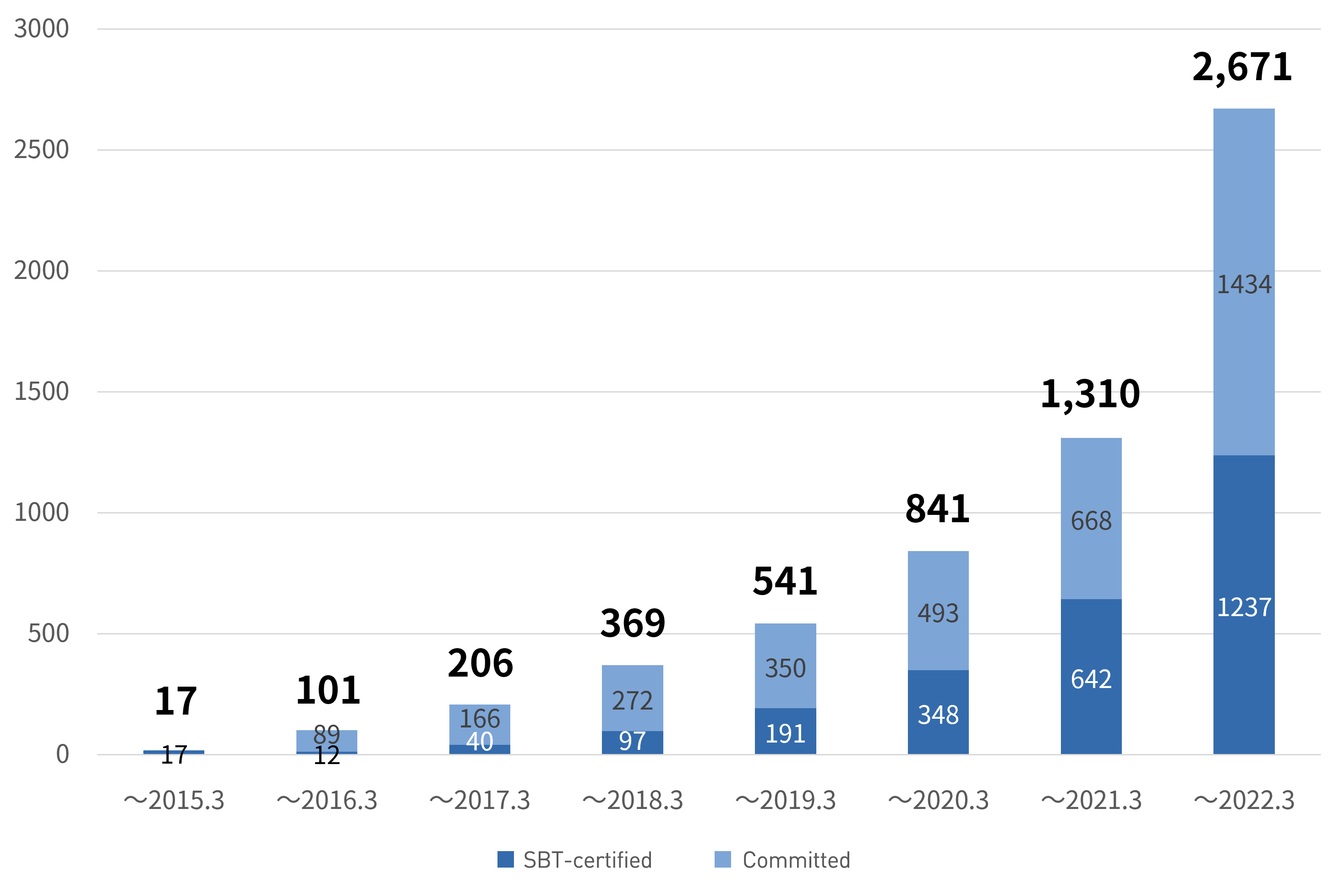

The global participation in the SBT initiative is steadily increasing each year, and we expect to see more and more companies requesting such decarbonization targets from their suppliers in the future.

Number of SBT-certified companies

*Number of SBT-certified companies: 1,237, Committed companies: 1,434, Total: 2,671 (as of March 17, 2022)

*Committed: Declared to acquire SBT certification within two years.

Source: Ministry of the Environment, 'SBT Detailed Material (updated March 17, 2022)'

In the future, failing to embrace decarbonization could result in business risks, such as not being selected as a procurement partner. On the other hand, a firm commitment to decarbonization emphasizes our stance as an environmentally conscious business.

How to reduce CO2 emissions in the manufacturing industry

The whole DMG MORI Group has been a pioneer in efforts to achieve a sustainable society, with the key focus on reducing CO2 emissions. Since 2021, we contributed to a significant reduction of CO2 emissions throughout our entire supply chain, from the manufacturing of raw materials upstream to product shipment, covering Scope 1, Scope 2, and Scope 3.

*For more information on our initiatives, please visit our Sustainability website.

Below are some strategies that we implemented to minimize CO2 emissions.

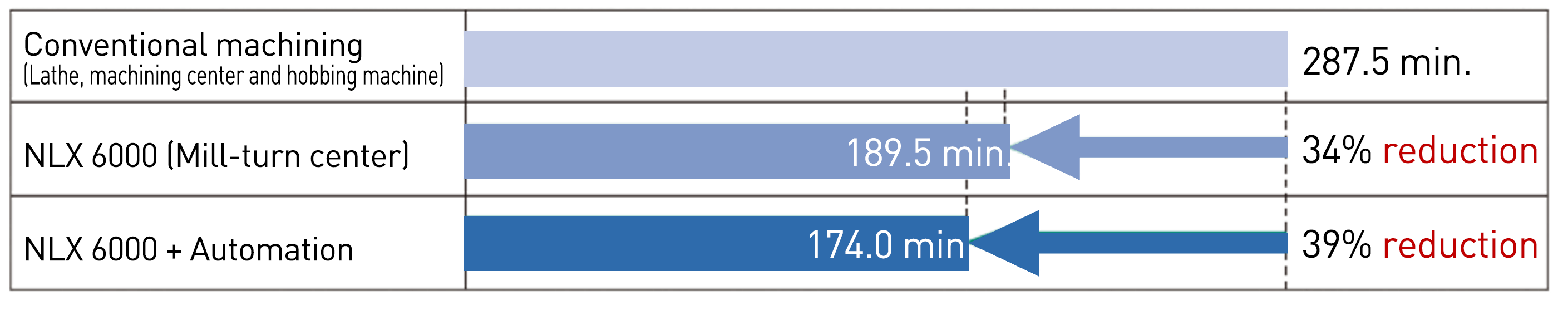

Process integration and automation

Machine tools are a major source of CO2 emissions in production due to their electricity consumption. Reducing the number of machines and minimizing idle time through process integration and automation can significantly cut CO2 emissions while enhancing delivery times and overall production efficiency. In our flywheel machining experiments, we compared traditional methods with streamlined approaches involving process integration and automation. The results were impressive — a 34% reduction in production time with process integration (using mill-turn machines) and an outstanding 39% reduction with added automation. Process integration and automation not only minimize CO2 emissions but also ensure a cleaner and more environmentally friendly production process.

Sample workpiece: Flywheel

・Size: ⌀505×120mm

・Workpiece material

*S45C: Carbon steel for machine structural use

Cycle time example (Full processing of flywheel)

Replacement of outdated machines

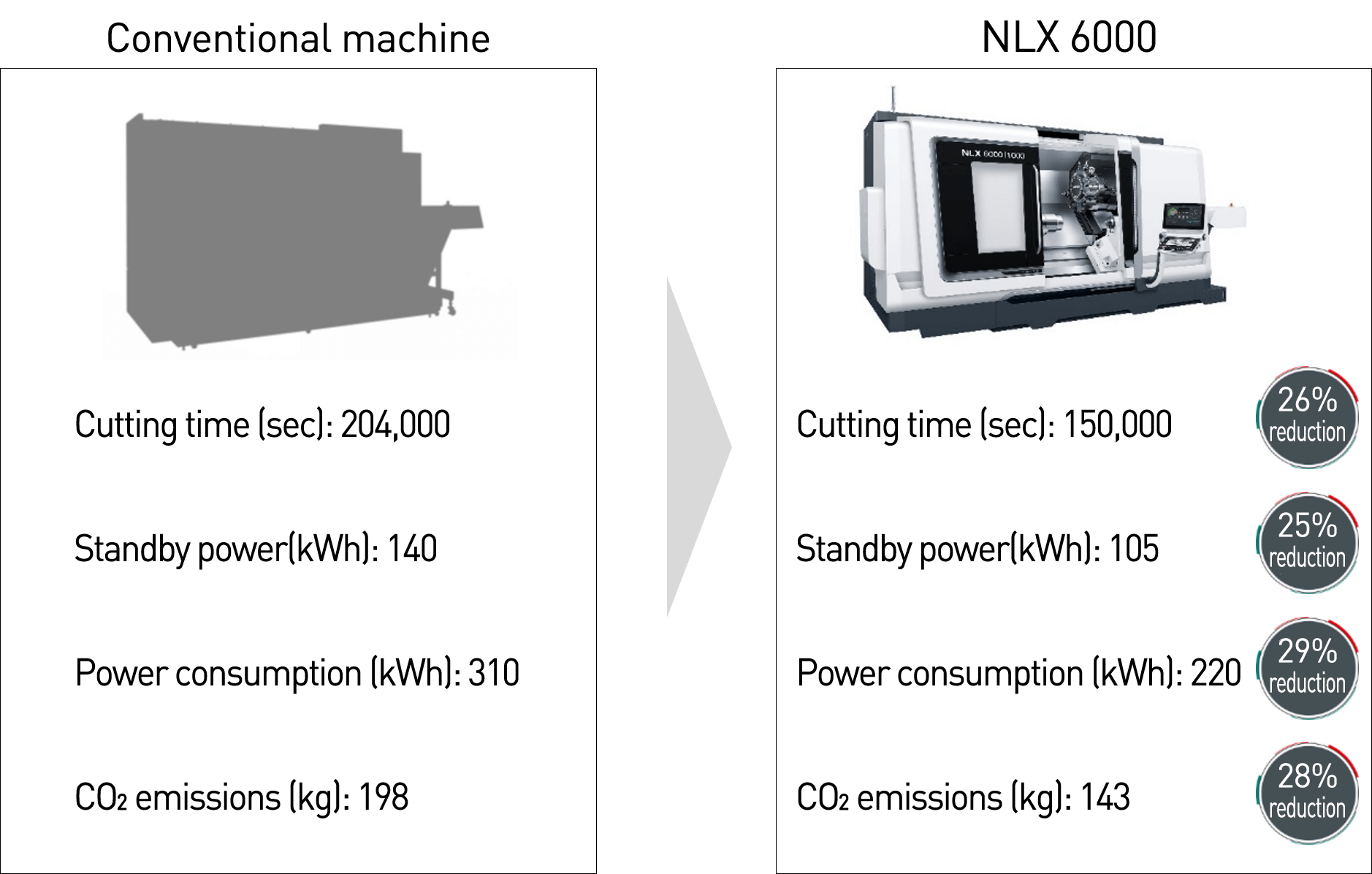

Upgrading to the latest machine tools presents a double advantage. With enhanced performance and reduced power consumption compared to older models, new machines enable more efficient processing in less time. This not only improves operation efficiency but also significantly contributes to CO2 reduction. Moreover, our latest machines come equipped with GREENMODE functions, offering additional potential for minimizing CO2 emissions.

GREEN Monitoring

Visualization of power consumption and CO2 emissions

GREEN device

Bright LED illumination

Hydraulic pumps equipped with inverter

GREEN idle reduction

Power to parts such as the servo motor, main drive, and

coolant pump is stopped when the machine is stopped

Turns off operation panel screen

when there is no operation for a certain period of time.

GREEN control

Quicker standard M code

Coolant discharge controlled using inverter

A comparison of our previous and new machine models indicates a 28% reduction in CO2 emissions with new machines.

Energy saving effect of new machine tools (O.D. machining of flywheel, 1,000 pieces)

Summary

Decarbonization will play a crucial role in the future. We need to promote initiatives to reduce CO2 emissions not only to fulfill our social responsibilities, but also to maintain our business competitiveness. Please visit us at our Iga Campus if you are interested to learn more about our sustainability initiatives and expertise.