- Top page

- About Machine Tools

The Role of Machine Tools

Machine tools are the silent architects of our modern world. Utilizing cutting-edge tools, these sophisticated machines take raw materials and mold them into the intricate components that propel industries forward, whether it's the dependable engine of an aircraft navigating through challenging conditions or the cutting-edge smartphone you hold in your hand. At DMG MORI, we understand that the precision of machine tools directly influences the accuracy and quality of the end products that shape our world. Our unwavering commitment to engineering top-tier machine tools not only empowers industries but also lays the foundation for a more reliable and efficient society.

Machine tools are in constant need

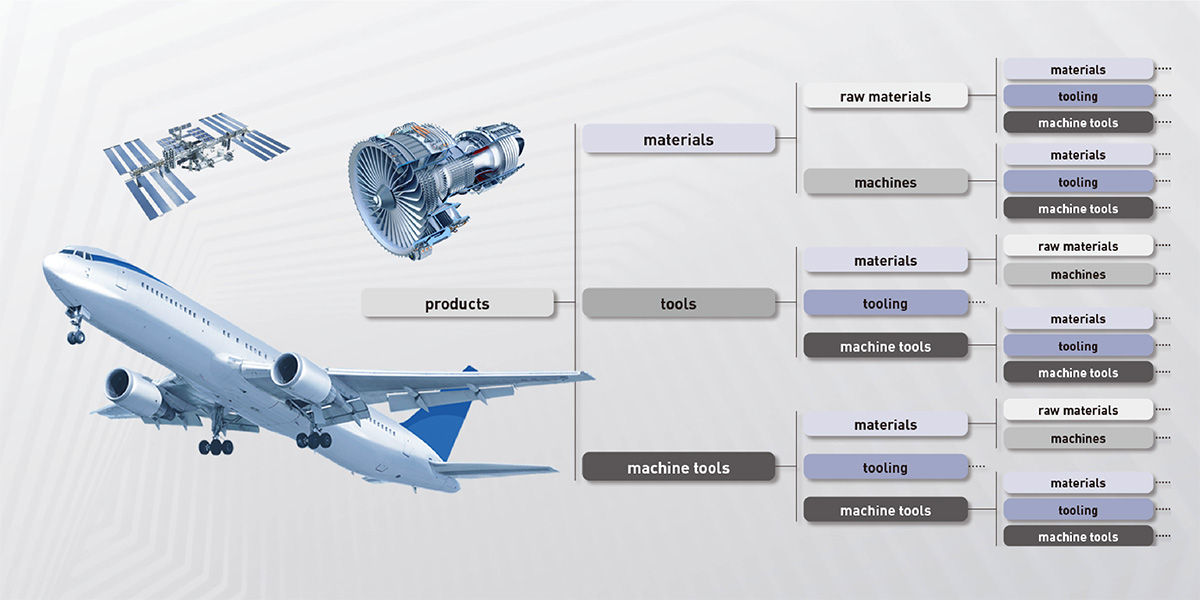

Every product has a unique life-cycle. Generally, this cycle starts with material extraction from natural resources and continues with refinement and manufacturing into a product. At each stage, machine tools, tooling, and materials are the three main contributing factors. If we take an automobile for example, we see that its parts are either processed directly on machine tools or shaped by metallic molds made by machine tools, and even the raw material is gained and prepared by machine tools. Therefore, regardless of how automobiles will evolve in the future, their structure will remain the same. In other words, the machine tool will continue to be an integral part of our lives, also in the future.

Crafting Precision Below 1 µm

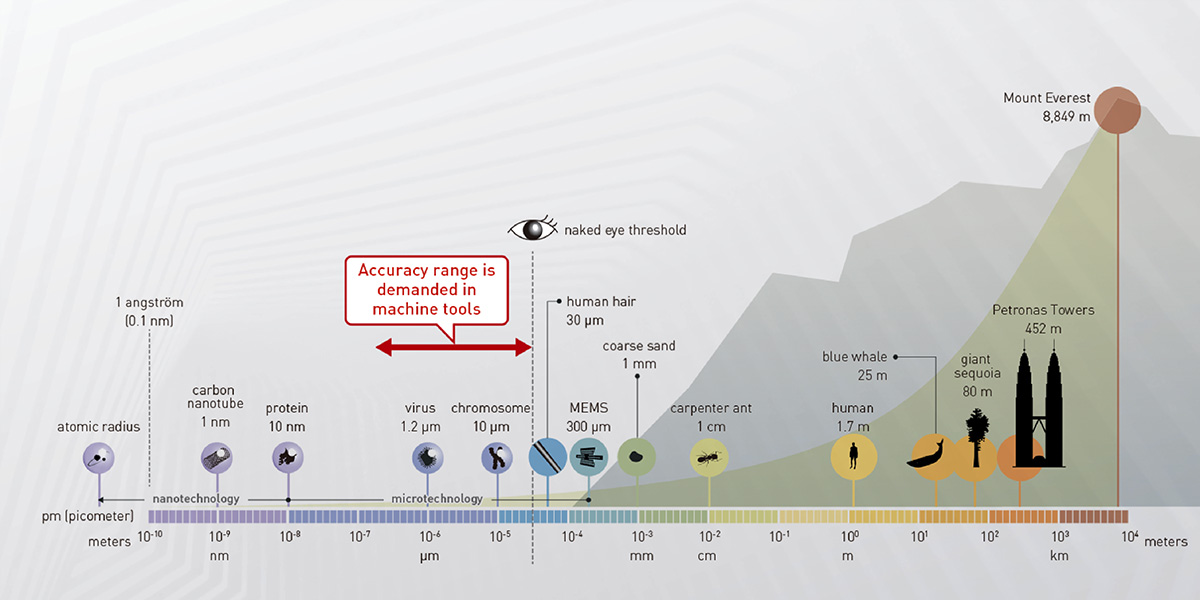

As consumers seek nothing less than the highest quality, manufacturers must deliver products with unparalleled precision. Machine tools are no exception. The accuracy of machine tools has a profound impact on the final product quality. With the remarkable ability to machine at micron and sub-micron levels, invisible to the human eye, machine tools are able to produce components with utmost precision. With our advanced technologies and expertise, we will continue to meet the precision demands of the manufacturing world.

出典:the PATH of PRECISION

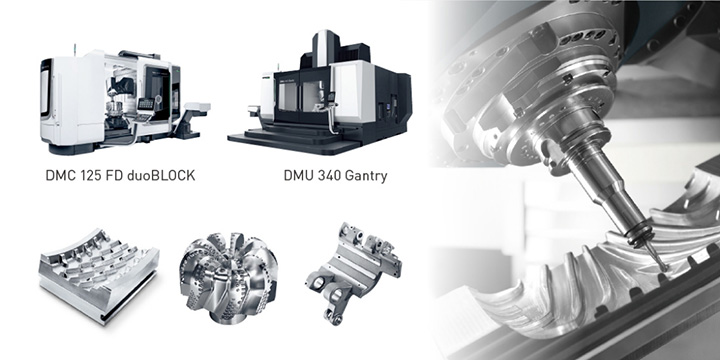

DMG MORI's Product Lineup

DMG MORI is a leading provider of high-performance, high-efficiency machine tools. With a rich foundation built on tradition, wisdom, and the collective efforts of our global workforce, we have developed an extensive and top-tier product lineup to cater to the unique needs and desires of every customer.