Additive Manufacturing Fundamentals - Why now is the right time to introduce AM? -

What is Additive Manufacturing?

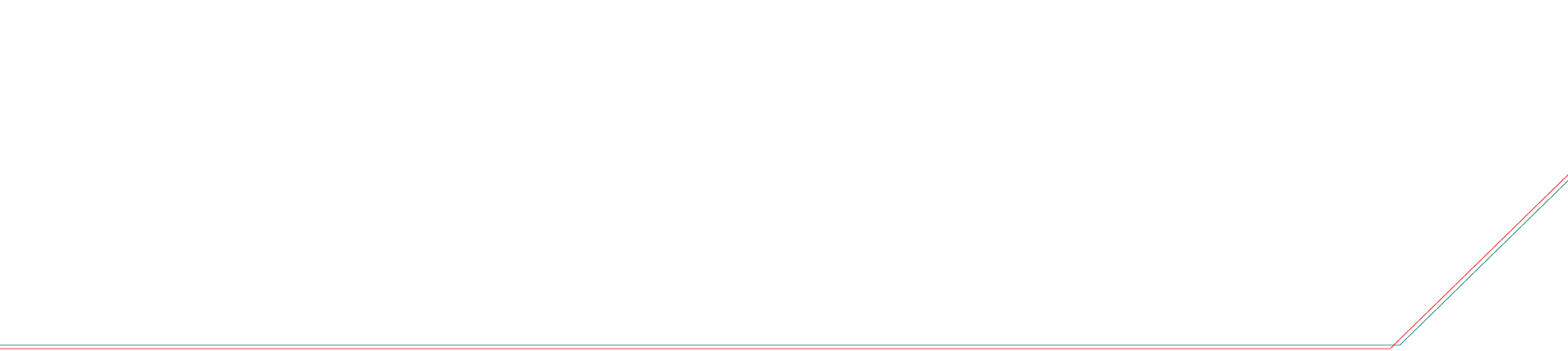

Additive Manufacturing (AM) is a manufacturing process that creates a 3-dimenional object by adding a metal material layer by layer.It is also known as "Metal 3D printing" or "Metal Additive Manufacturing."

Generally, metal is machined by Subtractive Manufacturing (SM) which, as the name suggests, creates a part by removing material from a solid block by cutting.

In recent years, Additive Manufacturing has attracted manufacturers’ attention.

Why Adopt the AM Technology?

1

Rapidly expanding AM market

Today, additive-manufactured products have drawn much attention in various fields, and the AM-related markets including machines and powder materials have seen impressive growth. This trend is expected to continue, or even accelerate in the future.

2

One of the most suitable machining methods for ever-growing high-mix low-volume production demands

AM costs less in low-volume production

The conventional machining method, or SM, reduces the unit price by producing a large volume of products because it requires different fixtures and tools according to workpieces, whereas with AM, which requires no tool/fixture replacement, the unit price remains constant.

AM is more suitable for complex design

With SM, manufacturing costs increase in parallel with the complexity of workpiece design as complex design tends to require higher technical skills and/or extra setups. Meanwhile, AM can produce a workpiece that is identical to an object created by a program, so workpieces of any shape can be produced at a constant unit price regardless of design complexity.

AM costs less in lightweight design

SM takes more time and cost when machining a lightweight workpiece. On the other hand, AM can reduce both machining time and material cost by reducing workpiece weight, and as a result achieves a lower unit price.

3

The demand for machining of special shapes which is only possible by AM is expected to grow in the industry, as leading manufacturers are accelerating the introduction of AM machines.

Aerospace

Combustion chamber

Parts incorporating

conformal cooling pipes

Medical

Artificial joint

Dental implants tailored to

individual patients

Vehicle

Impeller

Prototypes that use the same materials as those used in

mass production

AM Methods and Technologies

Additive Manufacturing is a collective term for several manufacturing techniques.

The table below shows some typical methods that use metal powders.

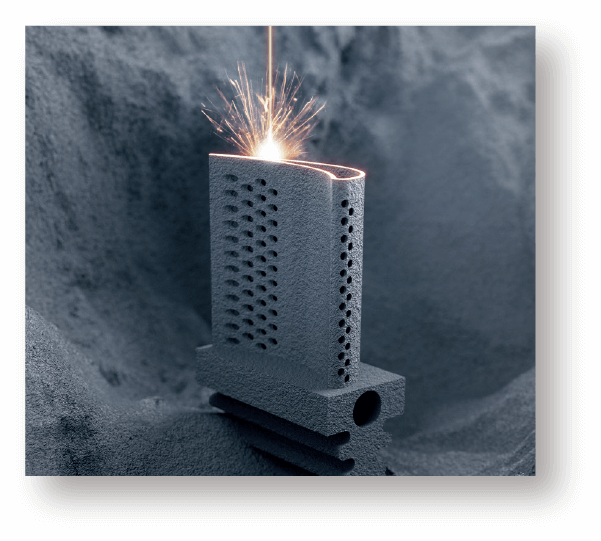

| Energy deposition DED (Direct Energy Deposition) |

Powder bed (SLM) PBF (Powder Bed Fusion) |

Binder jetting | |

|---|---|---|---|

|

|

|

|

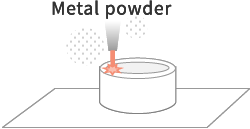

| Melts and irradiates metal powders through a nozzle to build them up. |

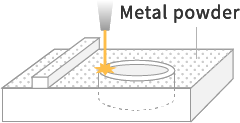

Irradiates laser beam to the surface across which metal powder is evenly distributed to build up. |

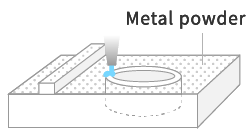

Applies resin to the surface across which metal powder is evenly distributed to build up. |

|

| Advantages |

|

|

|

| Disadvantages |

|

|

|

| Target |

|

|

|

There are other methods that use wires, sheets or pellets instead of metal powders.

Next, we explain one of the major AM techniques of powder bed fusion, or selective laser melting (SLM).