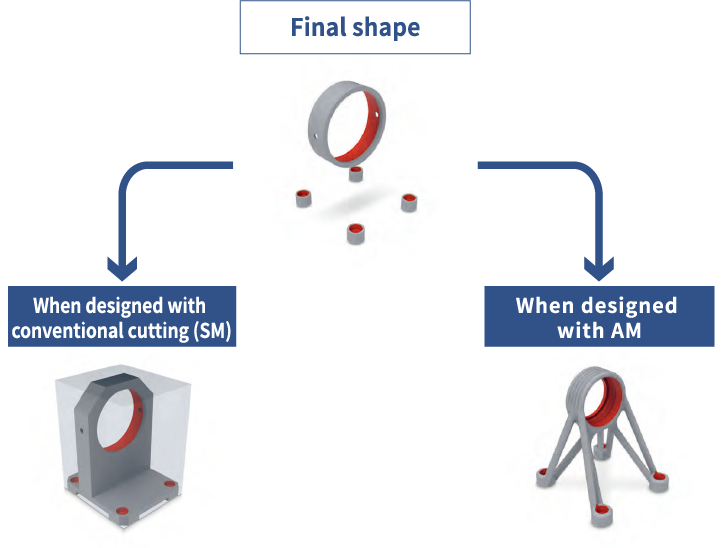

When designed with conventional cutting (SM)

- Design should be done according to material shape.

- Large amounts of material need to be cut waste of material.

- Some shapes are difficult to cut

The most distinctive feature is that this method creates an object from scratch, so a workpiece can be designed regardless of the original shape of metal.

This allows for more flexible design and creation of shapes that are difficult to achieve by cutting.

When designed with conventional cutting (SM)

When designed with AM

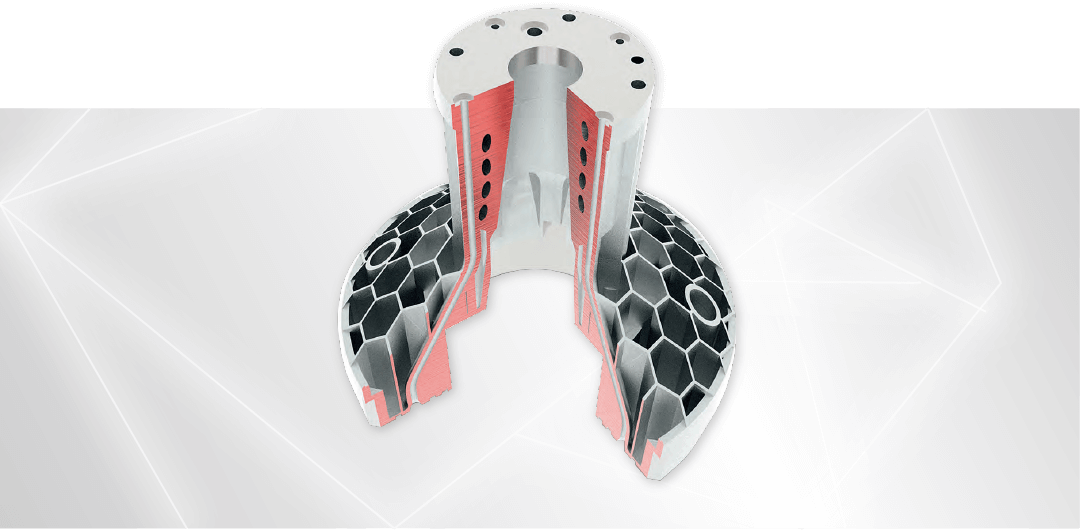

You can see the features and advantages of SLM in our machining of a powder nozzle body

on the LASERTEC 65 3D hybrid.