Logistics Initiatives

Our Initiatives

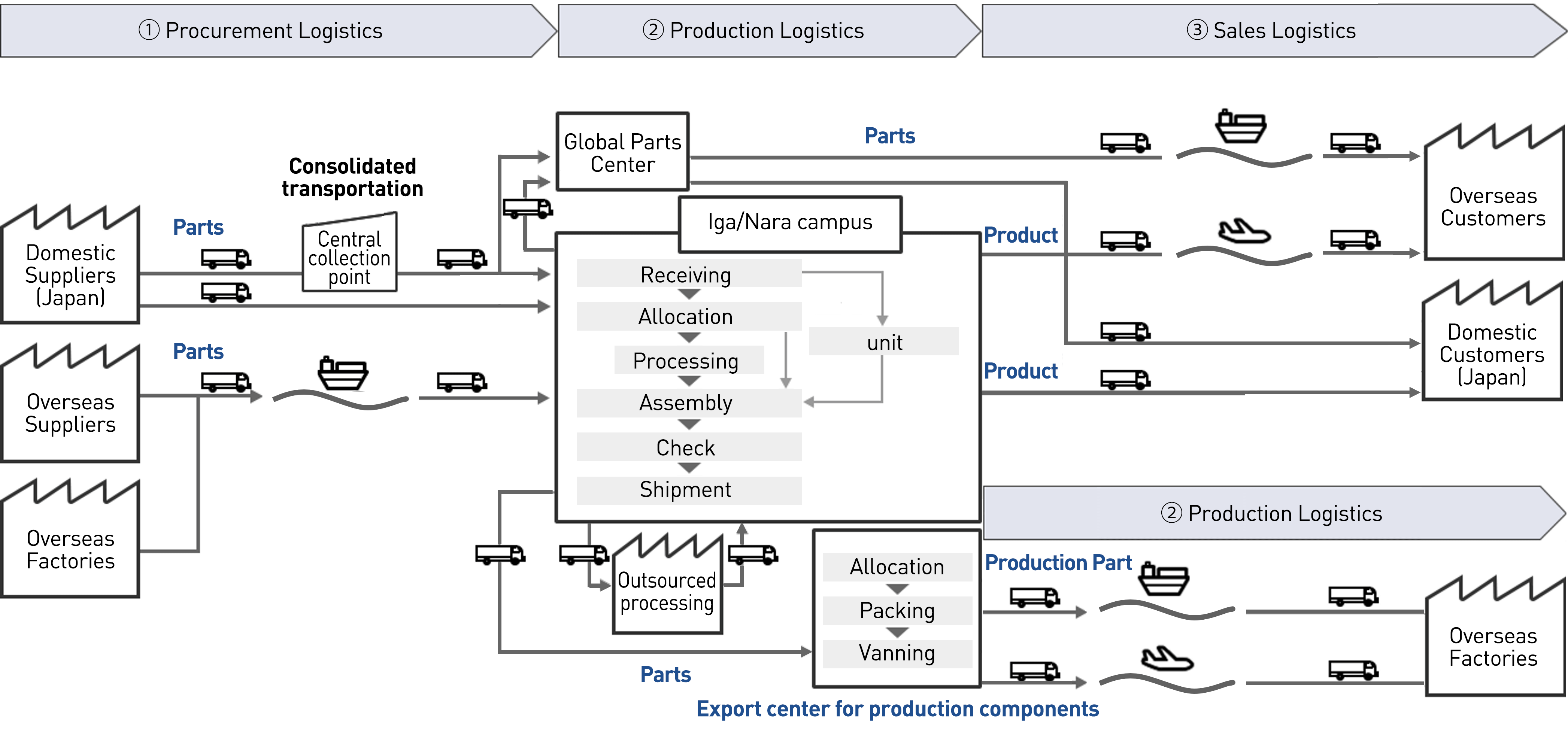

We manage our logistics through distinct processes, including “procurement logistics” for acquiring necessary parts and materials for production and service, “production logistics” for supplying components to assembly processes across domestic and international production bases, and "sales logistics" for delivering finished products and parts to customers. Throughout each step of these logistics processes, we are committed to environmental and social responsibility. This commitment is realized through collaborative efforts between DMG MORI, our suppliers, and transportation companies.

① Procurement Logistics

Start of consolidated transportation

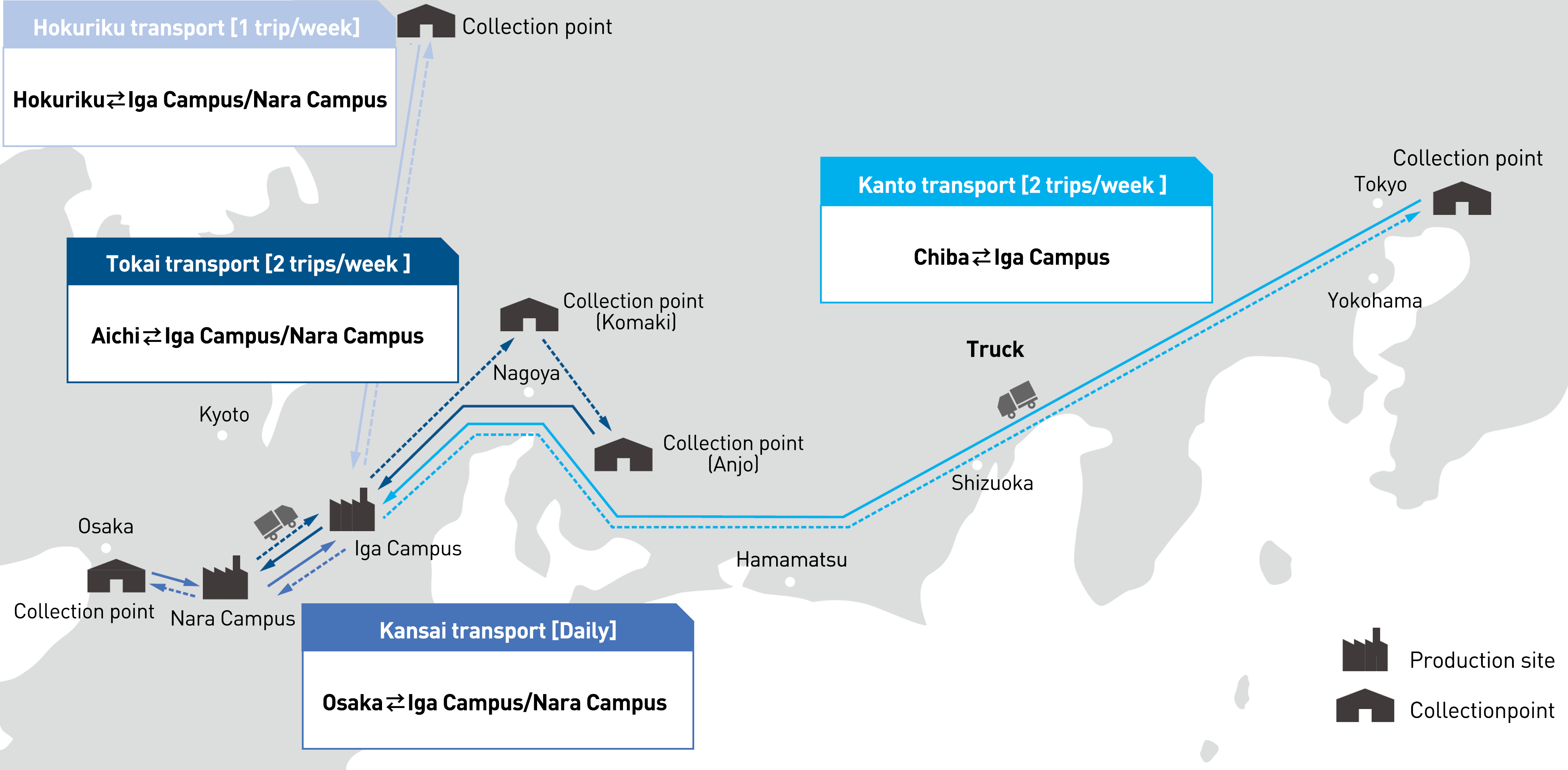

Since 2015, our in-house trucking service has facilitated the consolidated transportation of parts and materials. Strategic collection points in supplier-dense areas receive scheduled deliveries, and we transport these parts and materials to our production sites. Truck trips align with production plans for optimal loading efficiency, utilizing a milk-run system alongside consolidated transportation. This not only enhances procurement logistics efficiency but also contributes to more sustainable processes. The reduced vehicle entries into our plant further improve on-site safety.

DMG MORI's consolidated transportation network (Regular schedule)

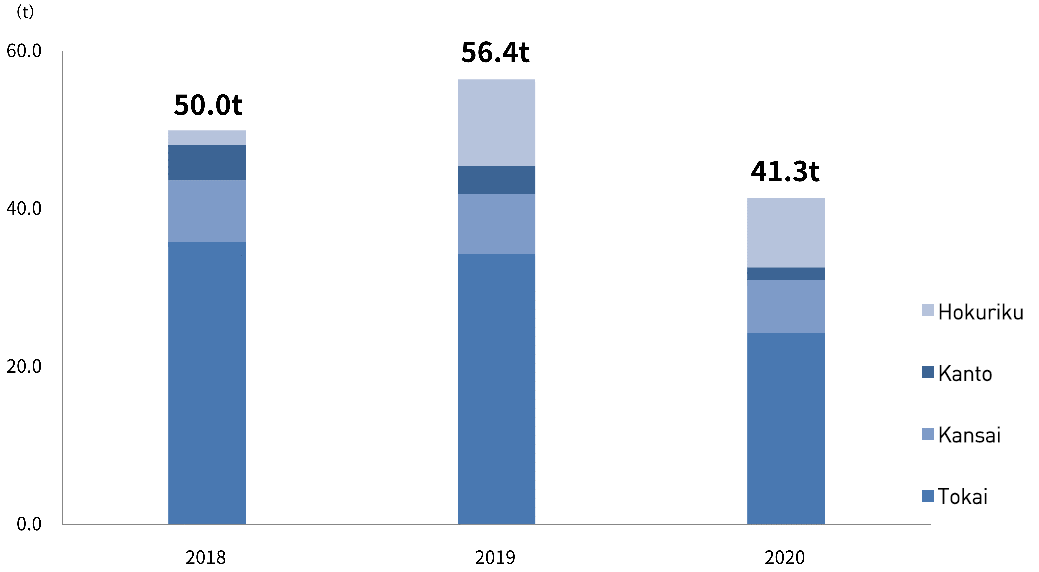

Environmental protection by reduced CO2 emissions

Consolidated transportation reduces the number of trucks used in procurement logistics and contributes to the reduction of CO2 emissions.

CO2 emission reductions from consolidated transportation

*Difference between total CO2 emissions of trucks arranged by suppliers and from consolidated transportation

② Production Logistics

Export of production components to overseas factories

The annual export of production components to overseas factories reached 3,104 tons in 2019. In 2014, we established a dedicated factory for the export of production components, creating a system that enables us to manage logistics quality in-house, reducing lead times and costs.

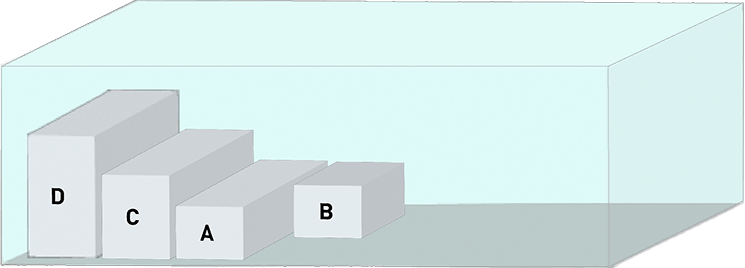

Use of Returnable Pallets

To enhance export efficiency, we replaced traditional wooden boxes and skids with returnable steel pallets as export containers. This shift addresses previous challenges such as wood disposal, low loading rates, and the risk of wood chips during packing. Designed to match marine container dimensions, the returnable steel pallets optimize space usage, resulting in improved loading efficiency with 70% less shipping containers required. Furthermore, the reusable nature of steel pallets contributed to a significant 38.7-ton reduction in wood usage in 2019.

Types of returnable pallets

- A: Small to medium-sized cast parts and equipment

- B: Precision parts such as spindles, turrets, etc.

- C: Parts with heights exceeding A, such as tables, ATC units, etc.

- D: Parts with heights exceeding C, such as protectors, sheet metal, etc.

Packing

Shipping (vanning)

Clean containers

As a measure against fire ants, an invasive alien species posing a recent threat, we thoroughly inspect the inside of containers before use, spray them with insecticide, and confirm the implementation of countermeasures using a control chart.

【Check items】

- ・ All containers shipped by DMG MORI

【Procedure】

- ・ Visual inspection of the inside and outside of containers

- ・ Spraying insecticide inside the containers

- ・ Confirmation of countermeasure implementation using a control chart

③ Sales Logistics

Initiatives in Domestic Transportation

For customers in Japan, our products are transported directly from our production sites to their factories through carrier trucks. Truck seats are made of canvas with our logo to improve customer satisfaction. Depending on the destination region and climate, the products are hermetically sealed and packed in transparent waterproof polyethylene sheets and packaged with a desiccant to prevent rusting.

Truck transporting products

Initiatives in Overseas Transportation

For overseas customers, products are transported by truck to the Port of Nagoya, carefully packed, and then shipped worldwide via container ships. To protect products during transport, we take measures against dust and rust by applying three layers of air caps (cushioning material to prevent scratches), barrier sheets (air-insulated with desiccant), and waterproof polyethylene sheets. Steel cases are used for packing. Steel cases reduce packing/unpacking time to around 1/3 compared to wooden boxes, thus reducing the workload.

Steel case packing

Barrier sheet and waterproof sheet packing

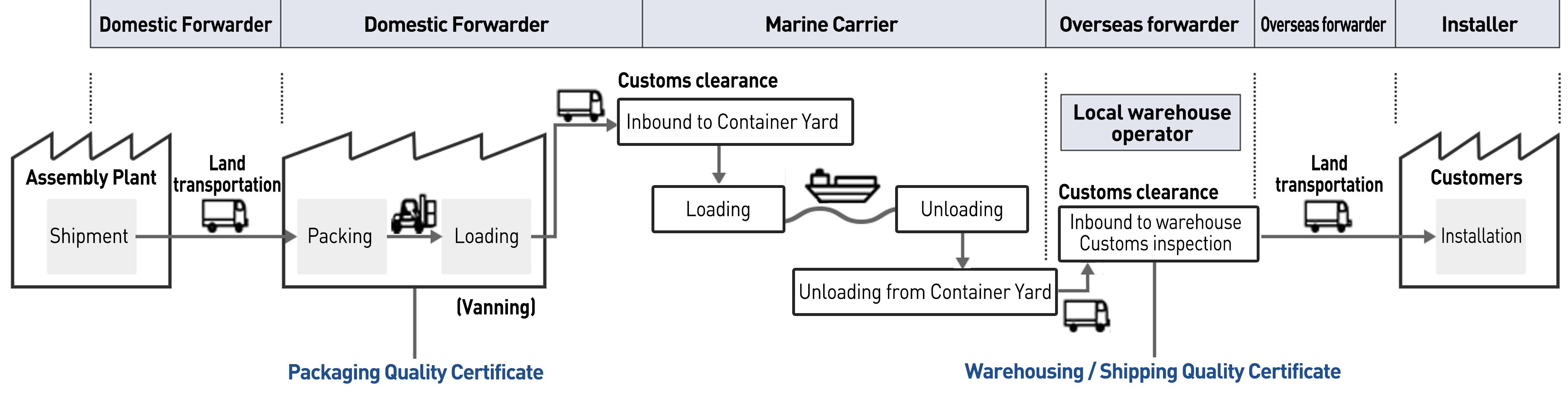

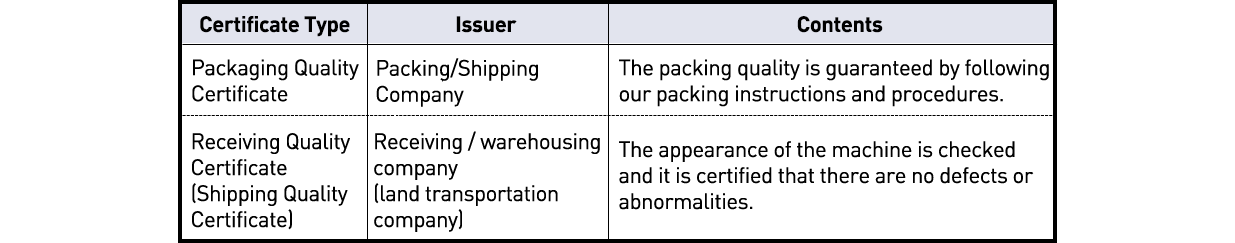

Logistics Quality Certificate

Products and components exported overseas undergo an extended delivery process involving various carriers. During transportation, minor flaws, rust, rainwater intrusion, and other defects may occur. In order to identify and trace where such defects occurred, we ask carriers to issue quality certificates at each stage of packing, shipping, and warehousing. We are enhancing logistics quality by strengthening our quality control system by thoroughly conducting quality checks at each process, allowing us to respond promptly to any defects that may occur.

Export Flow and Quality Certificate

Quality Certificate Types and Requirements

Future Initiatives

Striving for environmentally friendly logistics

The goal in logistics is to minimize its complexity and streamline processes into a more simple flow. Creating logistics that consider both back-end processes and customer needs holds the key to addressing environmental and social challenges. DMG MORI remains dedicated to contributing to the environment and society, building on the effective initiatives we have implemented thus far.