Global Environmental Conservation

The world’s average temperature has already risen over 1°C since the industrial revolution. We have been witnessing various damages caused by abnormal weathers such as large-scale floods and typhoons attributed to global warming.

The main cause of global warming is believed to be the increase in CO2 emissions from the combustion of fossil fuels, and there is no time to spare to reduce such emissions.

Under these circumstances, the Company is actively working to reduce its CO2 emissions. CO2 emissions are essential for the formation of a sustainable society and is a key issue in corporate social responsibility.

Active introduction of solar power generation facilities

The Company will strive to increase the utilization rate of renewable energy throughout the Group.

Specifically, the Company will switch from purchasing electricity to generating its own electricity from solar power. The Company has been promoting the introduction of CO2-free electricity throughout the Group since 2020. The Company’s factory, Iga Campus, introduced CO2-free power in April 2021. CO2 emissions related to electricity consumption at the Iga Campus is already zero, but the Company will further increase the use of renewable energy by introducing solar power generation facilities. Solar panels will be installed on the approximately 130,000 square meter factory roof throughout Iga Campus. The panels will have a capacity of approximately 13.4 megawatts, which will provide approximately 30% of the Iga Campus’s annual electricity demand. This is the largest on-site, self-consumption solar power system in Japan.

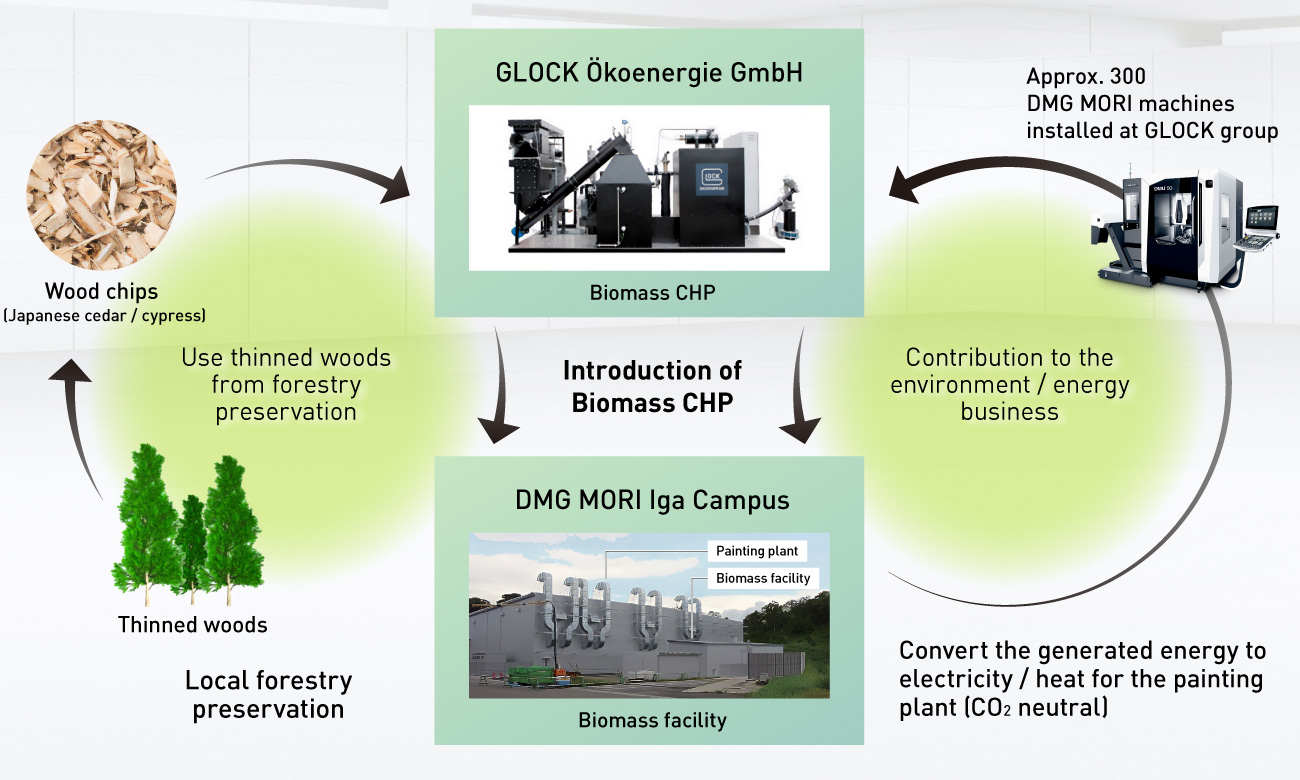

Introduction of biomass power generation system

In 2021, we introduced the biomass thermoelectric supply system in the paint factory on Iga Campus. The system equipped with high efficiency and energy-saving performance enables us to use as much as 96 percent of the output energy by generating electricity and heat. The use of the system not only reduces energy consumption of the company, but eliminates CO2 emissions as it is fueled by bio-derived wood chips, which is a characteristic of biomass. Furthermore, it protects environment and forest by use of thinned wood. Since the wood chips are purchased from local lumber companies, it contributes to creating local industries. This activity is one of our contributions to environment and local communities.

Promoting business strategies contributes to CO2 emissions reduction

Machining Transformation (MX)

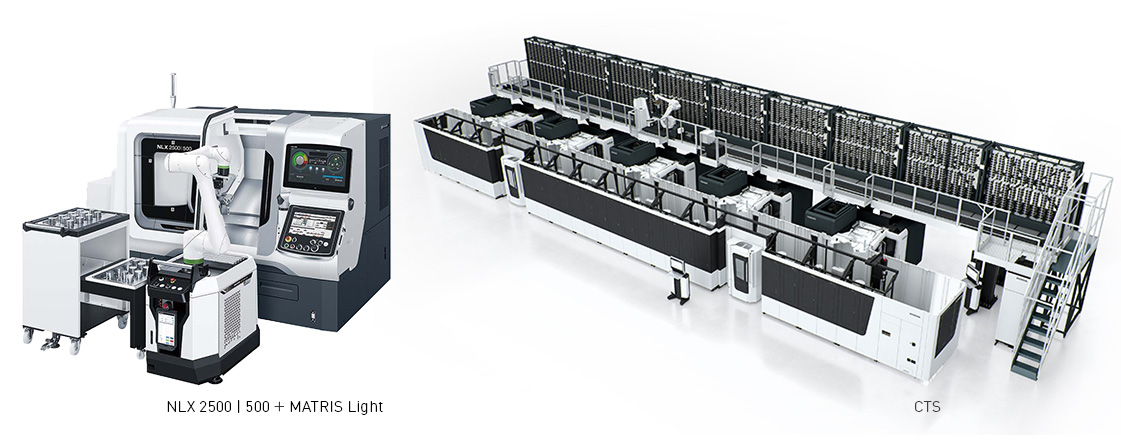

"The Company’s products contribute to green transformation at customer factories by improving productivity through process integration, automation, and digital transformation, and reducing CO2 emissions during their use by making products and peripheral equipment more energy efficient.

More specifically, the machining process, which used to be done on multiple machines, can be integrated by using 5-axis machines and mill-turn centers which is capable of simultaneous machining with single chucking. On top of process integration, automation solutions can reduce machine idling-time caused by loading and unloading workpieces or cleaning chips with air blow. The machining time per workpiece can be reduced by optimizing the machining process using digital twin technology. In this way, process integration, automation, and digital transformation, not only improve productivity, but also reduce power consumption and CO2 emissions by reducing the time spent for and between machining processes. Furthermore, the Company intends to make peripheral equipment, which accounts for about 70% of the power consumption required to process workpieces, more efficient and reduce related CO2 emissions."

Solution of three evils

In the world of subtractive machining, mist, chips, and coolant are known as the three evils, and they adversely affect machining accuracy and downtime of the machines. In order to solve these three evils, the Company developed and launched a new peripheral devices in 2021. Mist collector “zero FOG” reduces power consumption of the peripherals thanks to its optimally-designed mechanical parts, and “AI chip removal” recognizes the distribution and amount of chips in the machining chamber and stops the coolant pump when the amount of chips is low, thereby reducing power consumption. “Zero-Sludge Coolant” efficiently collects fine chips in the coolant tank, prevents them from building up in the tank, and inhibiting the growth of bacteria, thereby extending the replacement cycle time of the coolant oil due to decay. Extended life of coolant oil reduces the amount of oil waste and CO2 emissions associated with final disposal of coolant oil.