First-time 5-axis Control Machine Introduction Q&A

On-machine measurement system is new to us. Is that necessary?

Yes. An on-machine measuring system is necessary to achieve required parallelism and bring out the advantages of the 5-axis machine.

The system is easy to use; you can use it just by entering values according to the guidance.

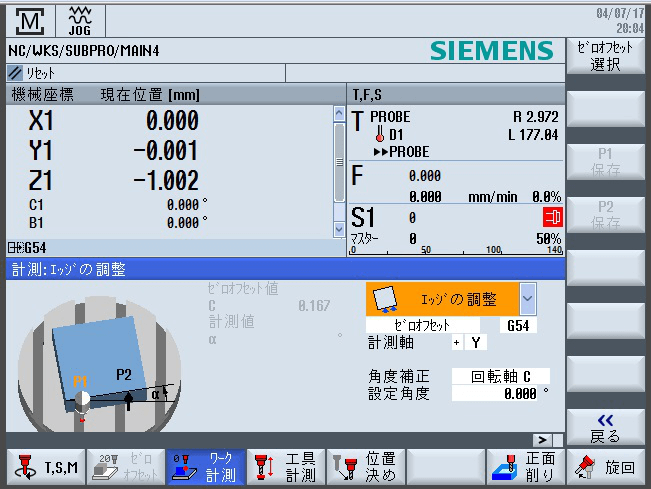

Example: Parallelism adjustment by means

of on-machine measurement system

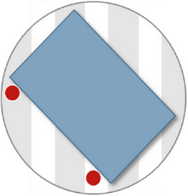

Measure the workpiece on the table at two positions

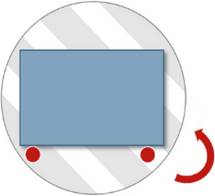

The table automatically rotates until the required parallelism is achieved

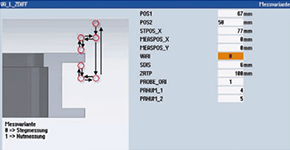

Easy operation by conversational input

Easy setting just by following the guidance on the screen

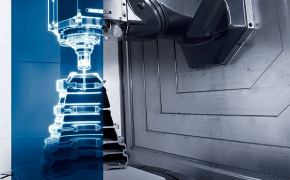

Easy measurement of complex geometries with DMG MORI’s exclusive Technology Cycles

Measurement with L-shaped probe

Support Programming for Measuring Grooves and Pockets

L-shaped probe measurement supports programming for measuring difficult-to-reach areas such as inside diameter grooves of flanges and valves. Parameters are input by the conversational programming method, which enables quick and easy measurement with an L-shaped probe.

DMG MORI’s 5-axis experts help you find the measurement system

right for you and explain how to use it