First-time 5-axis Control Machine Introduction Q&A

Not sure if 5-axis machines are effective for our workpieces

If your workpieces require machining of multiple faces, you can achieve shorter cutting time and higher accuracy. Many customers have achieved productivity gains after changing their machines from 3-axis to 5-axis.

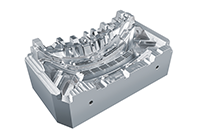

Case 1: Automobile parts (mold)

30%+ reduction in machining time

Improved surface quality

BEFORE

Before: 2 processes

Approx. 750 hrs.

AFTER

After: 1 process

Approx. 480 hrs.

Keys to successful introduction

- Tilt the spindle to perform cutting with the optimal tool face

- Tilt the workpiece to reduce tool overhang

Better surface quality

Electric discharge machining no longer required

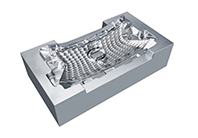

Case 2: Semiconductor manufacturing equipment parts (chamber)

80%+ reduction in machining time

BEFORE

Before: Three dedicated machines

Approx. 10 hrs.

AFTER

After: One 5-axis machine

Approx. 1.5 hrs.

Keys to successful introduction

- Machining of five faces in one chucking

Shorter machining time due to process integration

Case 3: Industrial machinery body

40%+ reduction in machining time

BEFORE

Before: approx. 5 hrs.

AFTER

After: approx. 3 hrs.

Keys to successful introduction

- 5-face machining of casting, which is difficult to clamp stably, can be done in one chucking

- High-speed, high-accuracy machining with linear drives

Shorter setup time due to process integration

Chatter suppression due to zero backlash

Our 5-axis machine experts explain what benefits you can expect from 5-axis machines and provide the best solution for your production issue.