Benefits by Industry / Workpiece

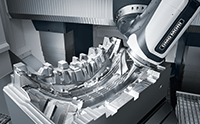

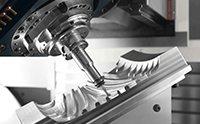

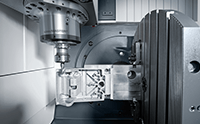

Die and mold

-

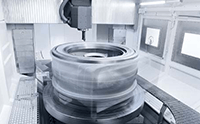

Concerns / problems

When workpieces with complex shapes and / or deep steps are cut, the amount of overhang becomes large, causing chatters

Machining of dies and molds requires quite a high degree of surface quality

-

5-axis control machining for

“highly accurate die & old machining”

As tables and axes are tilted, short tools can be used to machine deep areas

As a tool is tilted so that its optimal tool surface can be used, it contributes to higher workpiece surface quality

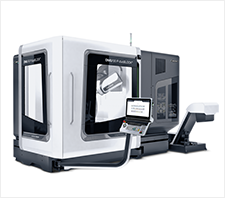

Products suited for die & mold machining

-

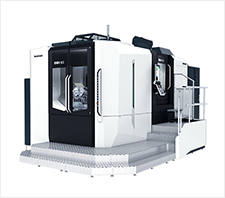

- DMU eVo Series

-

- duoBLOCK Series

-

- DMU P Series

-

- DMU Gantry Series

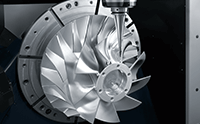

Prototype Parts

-

Concerns / problems

It takes time to prepare and produce special fixtures and tools

Hope to reduce setups as much as possible to achieve super short delivery times

-

5-axis control machining for

“prototyping with shorter delivery times”

Thanks to the tilted table, special fixtures and tools are not necessary

The number of setups can be reduced by process integration that ensures the turning and grinding functions on one machine

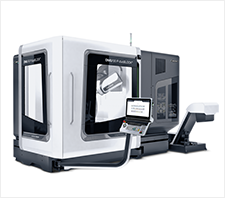

Products suited for prototype parts

-

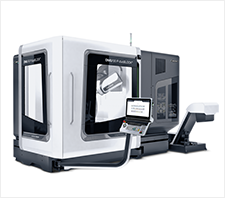

- DMU 50 3rd Generation

-

- monoBLOCK Series

-

- duoBLOCK Series

-

- DMU eVo Series

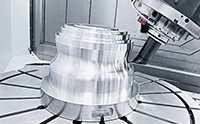

Aircraft Components

-

Concerns / problems

High cutting rates result in a large amount of chips

Setup changes are necessary because turning comes after milling to cut a special-shaped workpiece

-

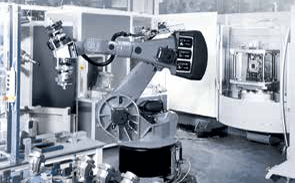

5-axis control machining for “unmanned operation for aircraft components and shorter delivery times”

Rotation of the table can realize high chip disposal performance

After a special-shaped workpiece has been machined, turning can be performed with no setup

Products suited for aircraft components

-

- monoBLOCK Series

-

- duoBLOCK Series

-

- DMU Gantry Series

-

- DMU eVo Series

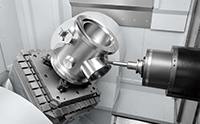

Semiconductor Manufacturing Equipment Chamber

-

Concerns / problems

As all five faces need to be machined, setups take time and errors may occur

-

5-axis control machining for “accuracy enhancement of semiconductor manufacturing equipment chambers and shorter delivery times”

Rotation of the table and axes enables machining in one chucking

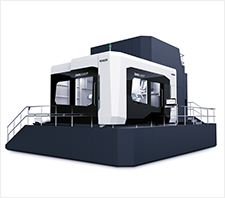

Products suited for semiconductor manufacturing equipment chambers

-

- duoBLOCK Series

-

- DMU eVo Series

-

- DMU Gantry Series

-

- INH Series

Industrial Machinery

-

Concerns / problems

It is difficult to chuck workpieces with many curved surfaces

-

5-axis control machining for “accuracy enhancement of industrial machineries and shorter delivery times”

Machining can be completed in one chucking

Products suited for industrial machinery

-

- duoBLOCK Series

-

- INH Series

-

- DMU eVo Series

-

- monoBLOCK Series