5-axis Control Machining Fundamentals

Features of 5-axis Control Machines

- What is 5-axis Control Machining?

-

- More flexible machining method that can be done on a machine with three linear axes (X, Y and Z) and additional two swivel rotary axes.

- Additional swivel rotary axes enable machining of more extensive areas in one setup.

- Machining is mainly grouped into two types depending on how the additional two axes are used.

-

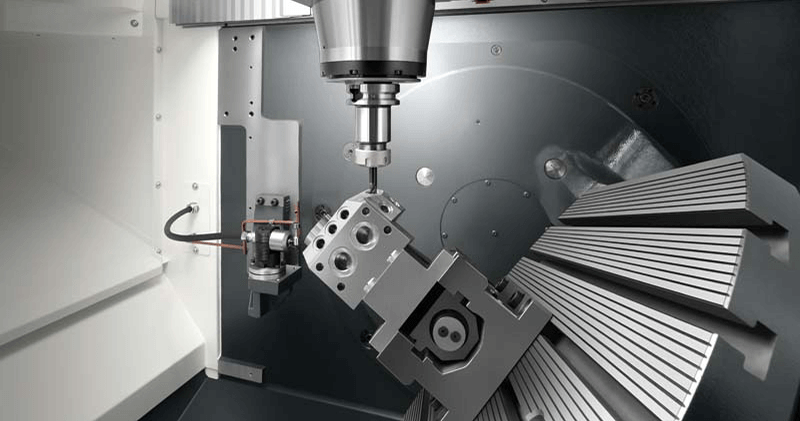

Indexing 5-axis machining

Machining is done on three linear axes with additional two axes positioned at any angle.

-

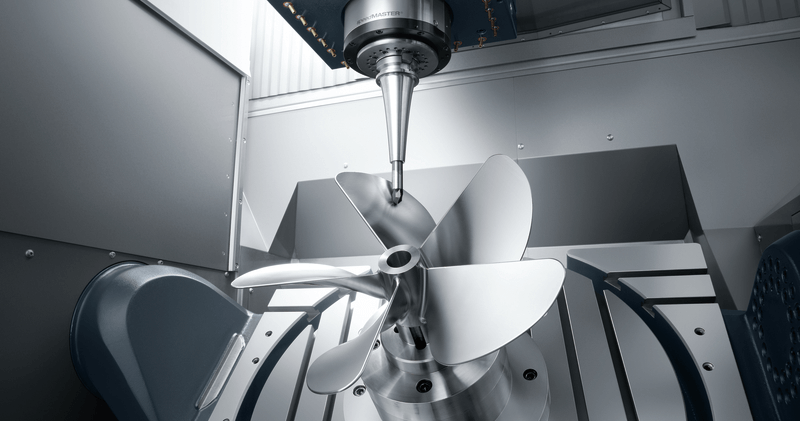

Simultaneous 5-axis machining

Two swivel rotary axes and three linear axes are synchronized to machine 3D curved surfaces.

Types of 5-axis Control Machines

5-axis control machines are mainly categorized into three types according to where swivel rotary axes are added.

-

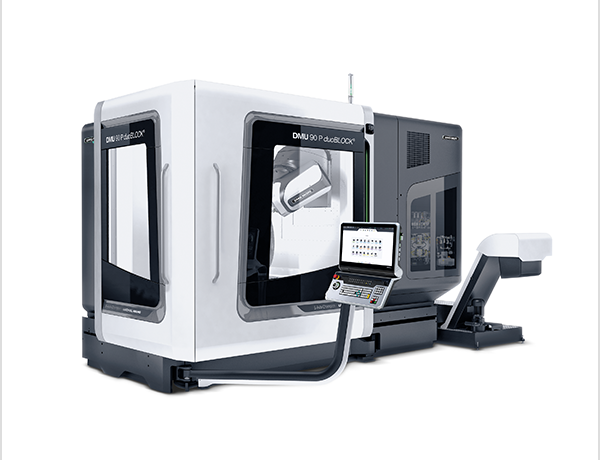

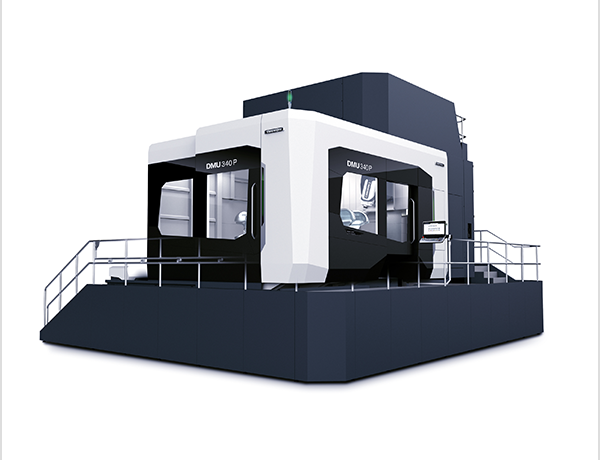

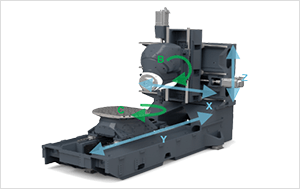

Swivel rotary table type

-

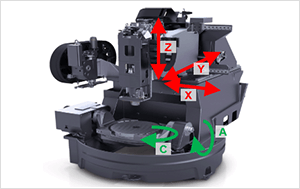

Swivel head rotary table type

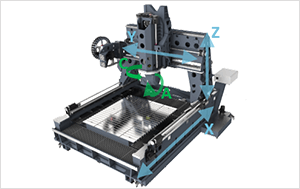

Representative Machines

-

Swivel rotary head type

Benefits of 5-axis Control Machining

5-axis control machines may be considered being used for workpieces with special shapes, but they actually offer a lot of advantages in machining general-shaped workpieces compared to 3-axis control machines.

-

Shorter machining time, higher machining

quality & accuracy- Reduction in setups

- Avoidance of a tool tip point where tool's peripheral speed becomes zero

-

Less machining cost, higher machining

quality & accuracy- No special tools required

-

Less

machining cost- No dedicated fixtures required