- HOME

- SUSTAINABILITY

- Supply Chain Management

- Logistics

Logistics

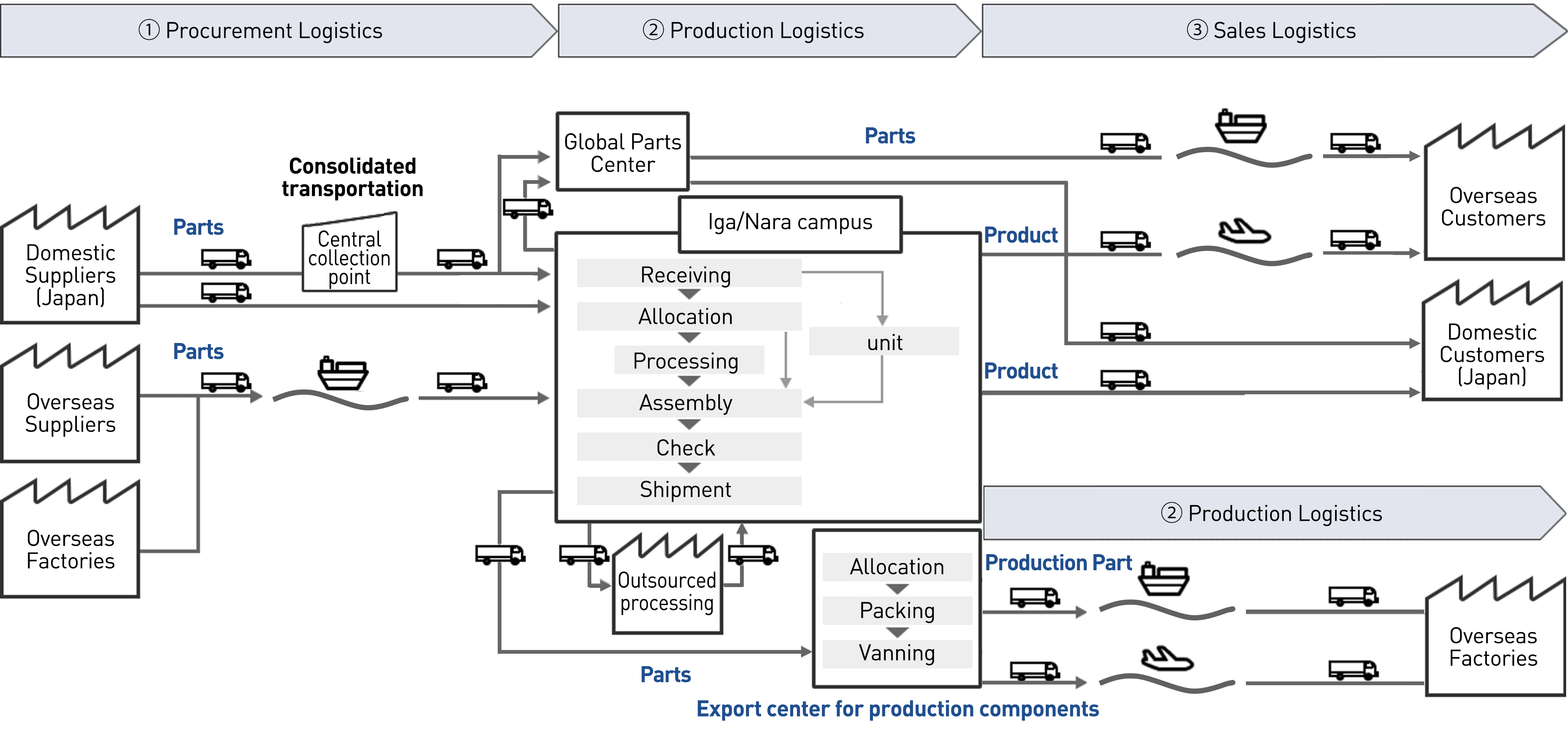

We believe in the need to address logistics efficiency throughout the entire supply chain to promote green logistics and respond to issues we encountered in 2024. We have long been committed to the environment, such as by promoting consolidated transportation and the use of returnable pallets, while also using DX to improve efficiency of internal and external parties involved and shorten time for parts delivery and loading/unloading.

We manage our logistics through distinct processes, including “procurement logistics” for acquiring necessary parts and materials for production and service, “production logistics” for supplying components to assembly processes across domestic and international production bases, and "sales logistics" for delivering finished products and parts to customers. Throughout each step of these logistics processes, we are committed to environmental and social responsibility. This commitment is realized through collaborative efforts between DMG MORI, our suppliers, and transportation companies.

①Procurement Logistics

Start of consolidated transportation

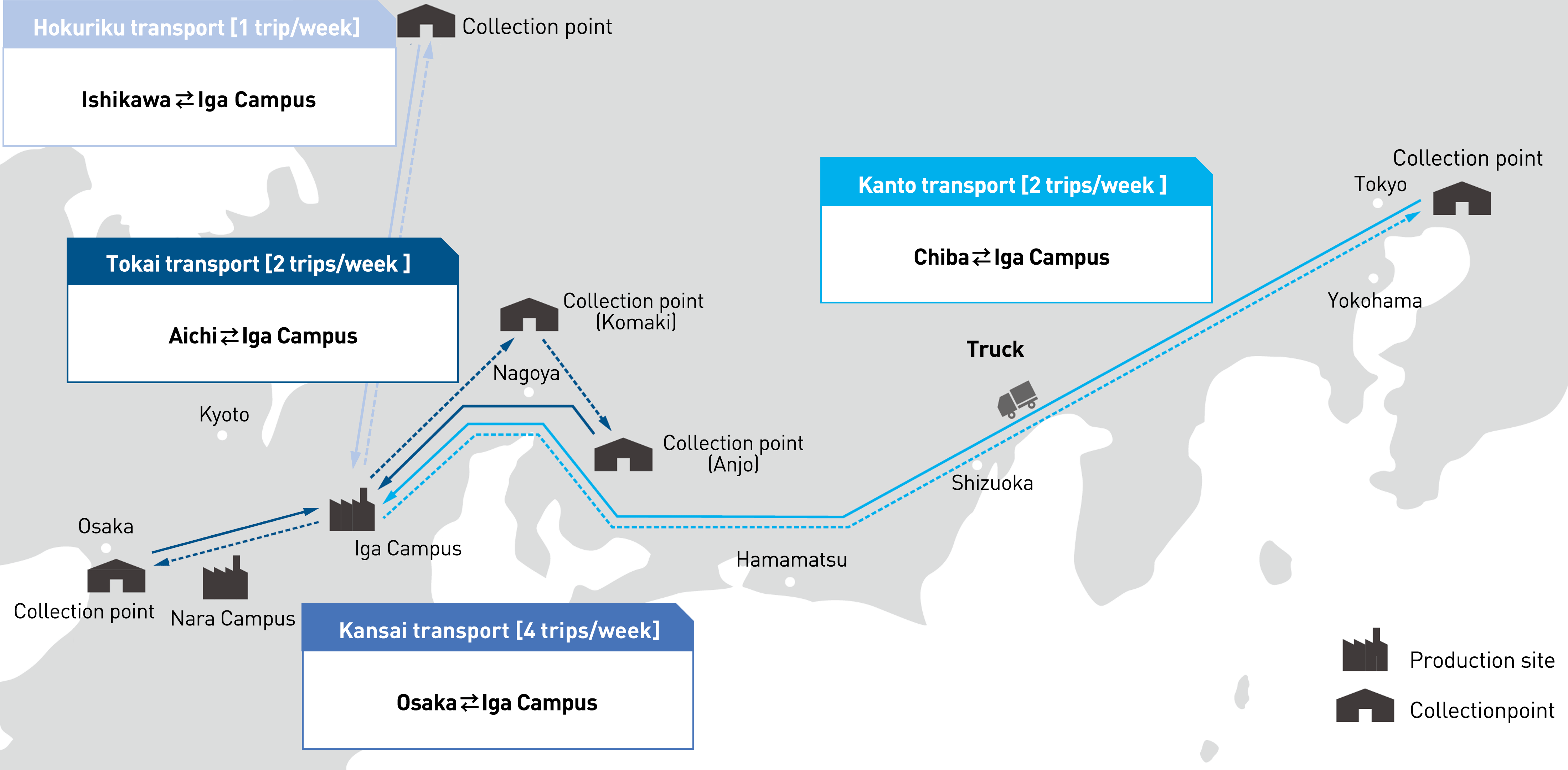

Since 2015, our in-house trucking service has facilitated the consolidated transportation of parts and materials. Strategic collection points in supplier-dense areas receive scheduled deliveries, and we transport these parts and materials to our production sites. Truck trips align with production plans for optimal loading efficiency, utilizing a milk-run system alongside consolidated transportation. This not only enhances procurement logistics efficiency but also contributes to more sustainable processes. The reduced vehicle entries into our plant further improve on-site safety. Consolidated transportation reduces the number of trucks used in procurement logistics and contributes to the reduction of CO2 emissions.

DMG MORI's consolidated transportation network (Regular schedule)

②Production Logistics

Export of key components to overseas factories

The annual export of key components to overseas factories reached 2,737 tons in 2023. In 2014, we established a dedicated plant to produce and export part kits for Japan-developed models and key components such as turrets and spindle units to our production bases in Europe, North America, China, and India. By establishing a system for managing logistics quality in-house, we have successfully shortened lead times and reduced logistics costs.

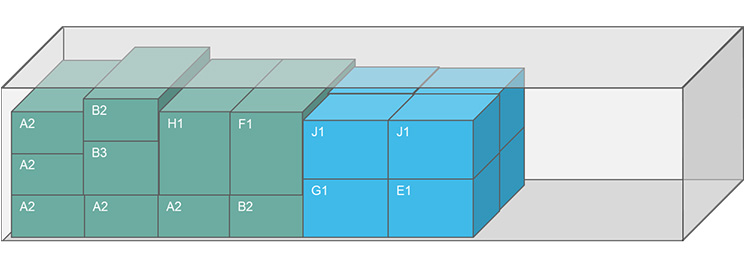

Use of Returnable Pallets

To enhance export efficiency, we replaced traditional wooden boxes and skids with returnable steel pallets as export containers. This shift addresses previous challenges such as wood disposal, low loading rates, and the risk of wood chips during packing. Designed to match marine container dimensions, the returnable steel pallets optimize space usage, resulting in improved loading efficiency with 70% less shipping containers required. Furthermore, the reusable nature of steel pallets contributed to a significant 294-ton reduction in wood usage in 2023.

|

<Types of returnable pallets>  JI pallet 3D-model JI pallet 3D-model |

Packing Packing |

Shipping (vanning) Shipping (vanning) |

Clean containers

With the rising threat of fire ants and invasive alien species, DMG MORI visually checks the inside and outside of all shipping containers before use, applies insecticides to the inside, and operates standardized, table-based process management.

③Sales Logistics

Initiatives in Domestic Transportation

For customers in Japan, our products are transported directly from our production sites to their factories by carrier trucks. We use curing clothes to prevent damage during transportation and truck sheets made of canvas with our logo. In addition, depending on the destination region and its climate, we pack our products hermetically sealed in transparent waterproof polyethylene sheets and include desiccants to prevent rusting.

Truck transporting products

Truck transporting productsInitiatives in Overseas Transportation

For overseas customers, products are transported by truck to the Port of Nagoya, carefully packed, and then shipped worldwide via container ships. To protect products during transport, we take measures against dust and rust by applying three layers of air caps (cushioning material to prevent scratches), barrier sheets (air-insulated with desiccant), and waterproof polyethylene sheets. The airtight steel case packing provides high durability and protects against moisture, while the total packing size and weight were reduced to make transportation more efficient. After use, the steel cases can be recycled as steel scrap.

Steel case packing

Steel case packing Barrier sheet and waterproof polyethylene sheet packing

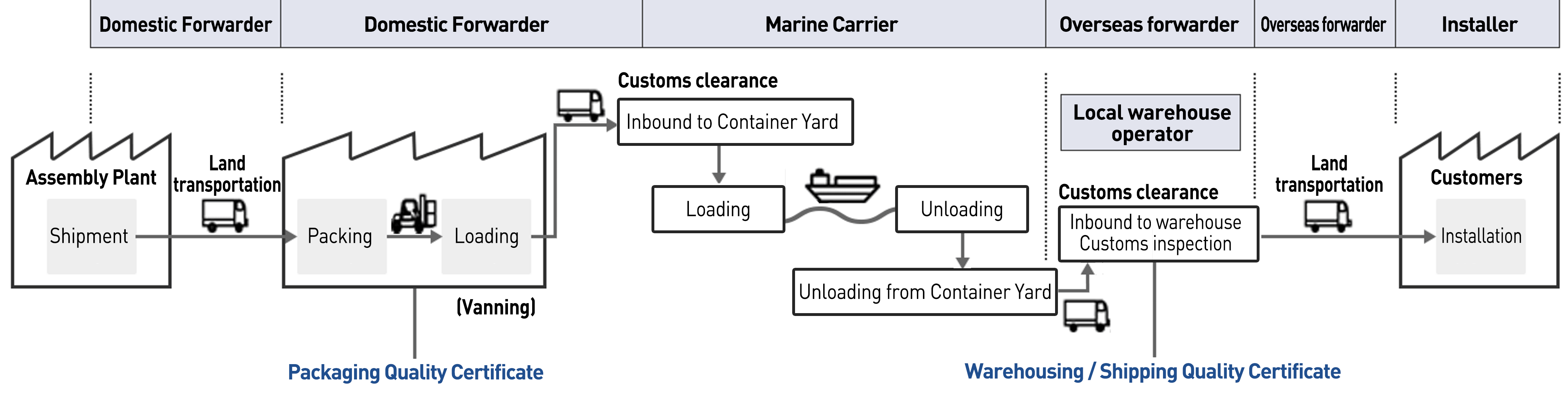

Barrier sheet and waterproof polyethylene sheet packingLogistics Quality Certificate

Products and components exported overseas undergo an extended delivery process involving various carriers. During transportation, minor flaws, rust, rainwater intrusion, and other defects may occur. In order to identify and trace where such defects occurred, we ask carriers to issue quality certificates at each stage of packing, warehousing, and shipping. We are enhancing logistics quality by strengthening our quality control system by thoroughly conducting quality checks at each process, allowing us to respond promptly to any defects that may occur.

Export Flow and Quality Certificate

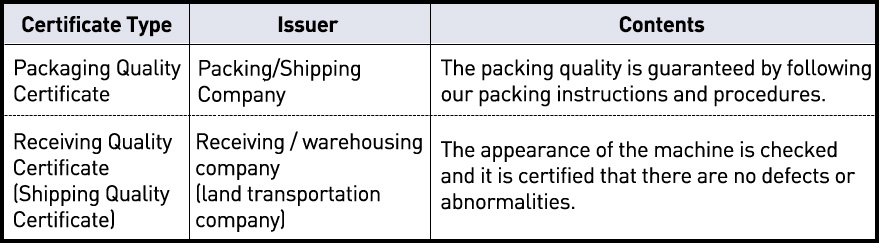

Quality Certificate Types and Requirements

Logistic measures 2024

With the revised Labor Standards Law to limit work hours of truck drivers effective as of April 2024, we are taking initiatives to improve logistics efficiency throughout the supply chain.

Cargo delivery time reduction

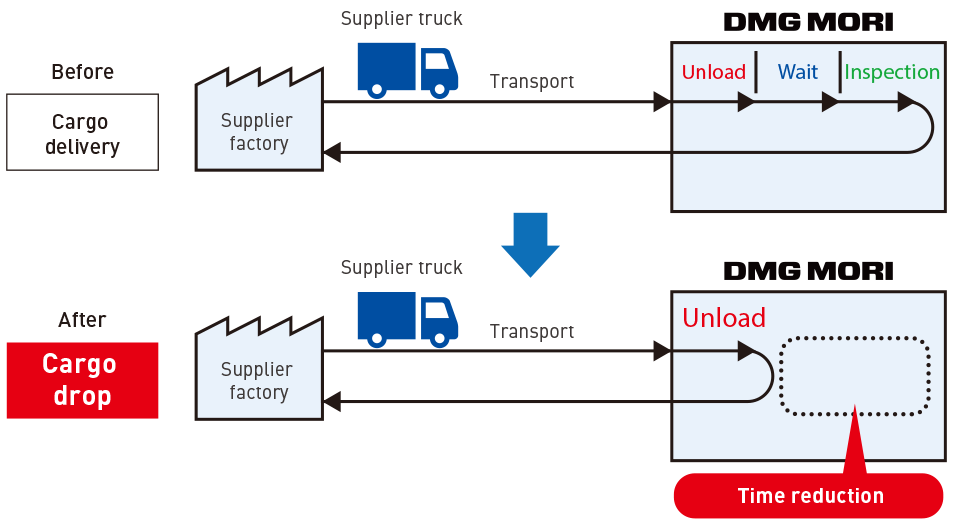

With the manufacturing support platform “TULIP” for easy app creation and digital problem solving, we identified bottlenecks by recording and analyzing work processes and times from arrival to acceptance of cargo. To reduce cargo loading/unloading to less than 1 hour, DMG MORI is implementing measures such as dropping off cargo, participating in consolidated transportation services, and continued process reviews.

Dropping off cargo allows drivers to leave right after unloading without having to wait for acceptance to be completed.

For partner companies unable to drop off cargo or use consolidated transportation, we are working on individualized measures for cargo delivery time reduction.

New: Cargo Drop Procedure

Reduction of time for cargo-related operations

To reduce the time for cargo waiting and loading/unloading, we have changed the layout of the shipping area, expanded parking space and reorganized the division/layout of lots. We are working to expand aisles, truck berths, and workspace.

Truck yard & Security gates

In October 2023, we built a truck yard for 5 trailers and 3 trucks as a waiting and resting area for drivers. In addition, we installed security gates Iga Campus that allow entry by number detection to eliminate the need for manual registration and avoid traffic congestion.

Truck yard

Truck yard Security gates

Security gates