- HOME

- SUSTAINABILITY

- Environment

- Functions & Machine Tool Lifecycle

- Procurement & Supply Chain

Procurement & Supply Chain

Reducing CO₂ emissions across the entire supply chain

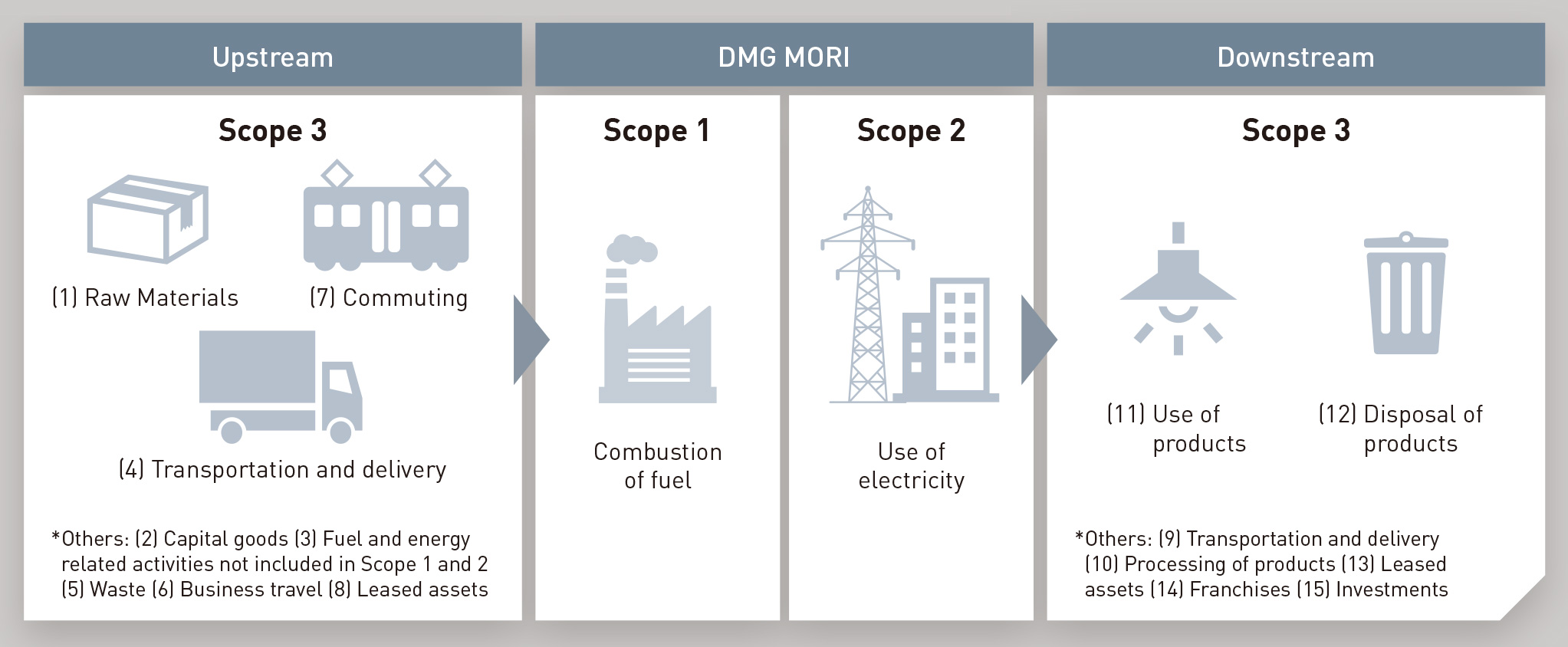

DMG MORI recognizes the importance of environmental responsibility across the entire lifecycle of its products – from procurement to disposal. Since 2021, the Company has been actively working to reduce CO₂ emissions across all upstream processes (Scopes 1, 2, and 3) from raw material production to shipment.

With its targets certified by the Science Based Targets initiative (SBTi) in 2021, the Company is committed to reducing CO₂ emissions across its entire supply chain.

Reducing CO₂ emissions across the entire supply chain

DMG MORI CASTECH

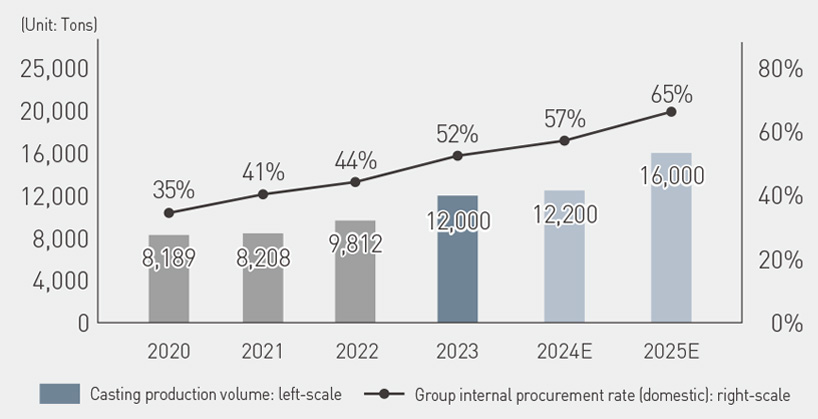

DMG MORI CASTECH CO., LTD. produces castings for beds and columns, which are key components of machine tools. Castings are crucial to the accuracy, rigidity, and durability of machine tools and must be supplied in a stable and high-quality manner. However, the production of castings involves significant amounts of CO2 emissions. In response, DMG MORI CASTECH began rebuilding its main plant in 2022 by expanding production capacity and upgrading equipment.

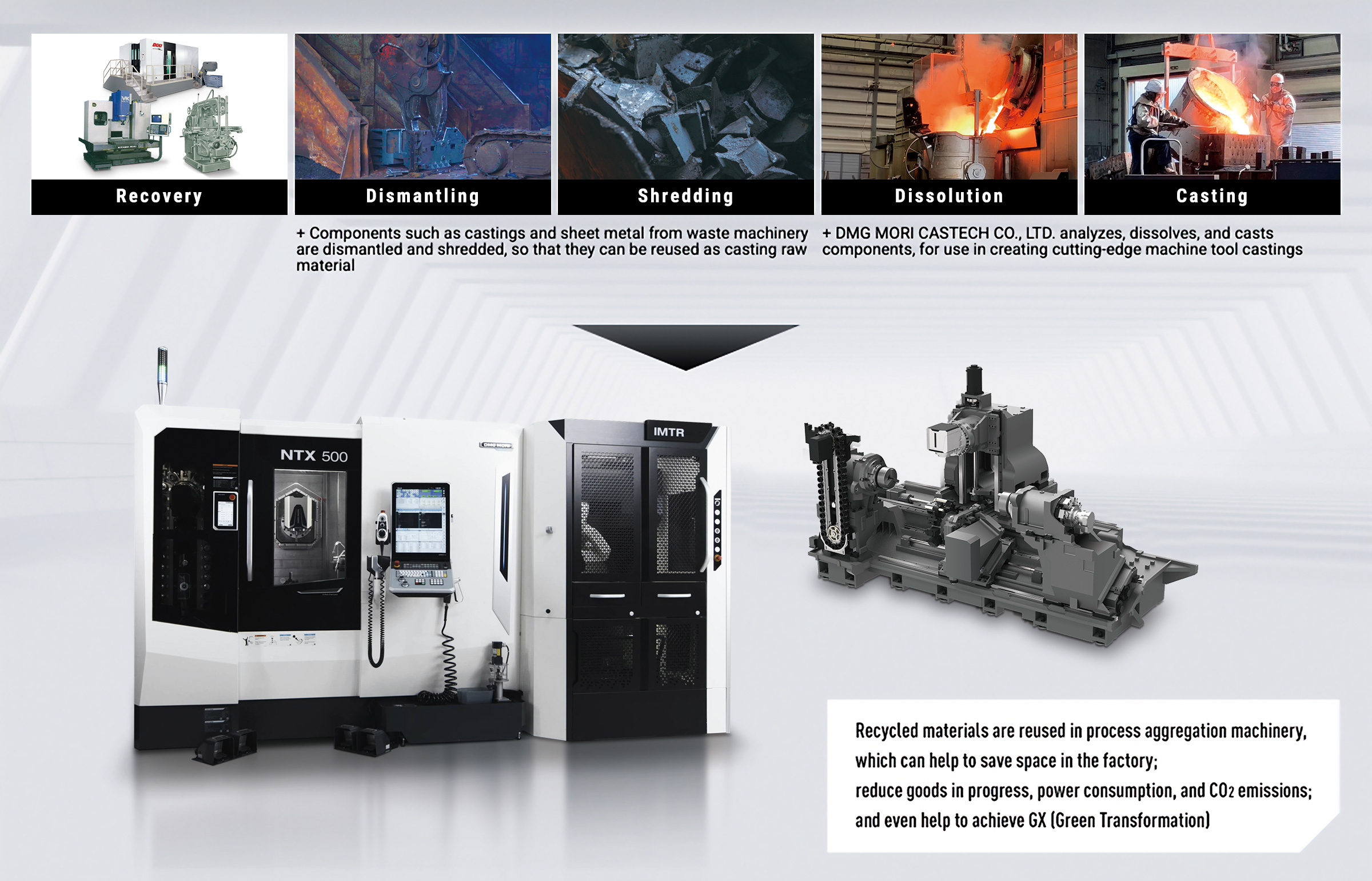

In 2024, DMG MORI CASTECH launched a new initiative to further reduce CO2 emissions by recycling castings from scrapped machine tools and cutting chips and transforming them into raw materials for new machines. DMG MORI CASTECH plans to complete the reconstruction of its main plant and fully upgrade its production system by 2030, thus increasing its annual casting production capacity from less than 12,000 tons in 2023 to about 30,000 tons by 2030. This will allow them to meet about 75% of the annual casting demand for domestic production sites with focus on large castings.

With the construction of the new plant, DMG MORI CASTECH abandoned conventional coke ovens in favor of electric furnaces in January 2023. The new electric furnaces utilize CO₂-free electricity and renewable energy, which will contribute to reducing the annual carbon footprint of DMG MORI CASTECH from 6,665 tons in 2020 to about 140 tons in 2025 (down 98% from 2020).

Expansion of casting production

DMG MORI CIRCULAR

DMG MORI CIRCULAR CO., LTD. was established in November 2023 to contribute to a circular economy. Their initiatives include overhauling and retrofitting of used machine tools as well as collecting machines at the end of their lifespan to dismantle and reuse them as scrap materials for the production of new casting components, including cutting chips from in-house and outsourced machining processes, which are separated from coolant before reuse. The melting and casting processes are carried out by DMG MORI CASTECH.

Green procurement

DMG MORI places the preservation of the environment as one of its priorities across all business activities in accordance with its philosophy of "valuing natural resources and protecting the planet." During procurement of raw materials, components, and equipment, the Company actively selects goods and services with a low environmental impact, including materials that avoid the use of hazardous substances and eco-friendly alternatives. Green procurement is one pillar of the Company’s promotion of sustainability.

Green procurement list examples

Coolant-related parts

Optimal control of high-efficiency coolant pump using an inverterMotor efficiency class: IE5

Motor type: Permanent magnet synchronous motor

Power/drive source: Inverter driven

Hydraulic-related parts

Optimal control of high-efficiency hydraulic unit using an inverterMotor efficiency class: IE4 equivalent

Motor type: IPM motor (speed control)

Drive source: Double variable using IPM motor and variable vane pump (variable delivery)