- HOME

- SUSTAINABILITY

- Environment

- Functions & Machine Tool Lifecycle

- Products and Customers

Products and Customers

Improved product design

The environment must be a top priority for the entire life cycle of a product, from procuring materials and parts to disposing of the product. The Company is committed to continuous product improvement and development by requiring each new product and model to reduce its environmental impact. This means reducing power consumption, size, and weight, but also includes the integration of multiple machines and processes into a single machine to boost productivity, cut CO2 emissions, and benefit the environment. The Company continues to limit or outright stop the use of hazardous chemical substances and actively promotes the procurement of eco-friendly parts and materials.

Development goal

New product models that emit 30% less CO₂ by FY 2030 (compared with FY 2018)

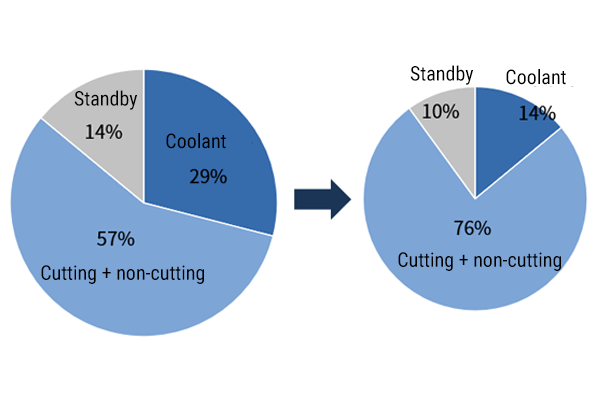

Example 1: Reduce power consumption per workpiece by reducing standby power consumption and coolant

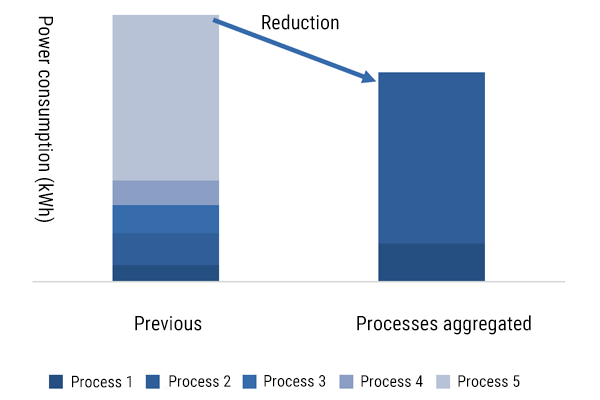

Example 2: Reduce power consumption through efficient machining (process aggregation)

Improved product use

CO₂ emissions from product use account for a large proportion of the product life cycle and require our attention. Since 2017, the Company has been installing its energy-saving function "GREENMODE" as standard on each machine tool, while also enhancing in-house production of peripheral equipment which is said to account for about 70% of the electricity used in machining processes.

During these processes, cutting chips, mist, and coolant are unavoidable factors that may impact machining accuracy and even cause machine shutdowns for long periods of time. In pursuit of a solution, the Company has been developing and selling new dedicated peripherals since 2021.

GREENMODE

GREENMODE visualizes and monitors power consumption and CO₂ emissions. It reduces unnecessary standby power, e.g., by shutting off servo motors, spindles, coolant pumps, and other idle units when the machine is stopped, or by turning off the control panel screen outside of machine operation. In addition, during actual machining, the utilization of efficient programs reduces machining time and power consumption.

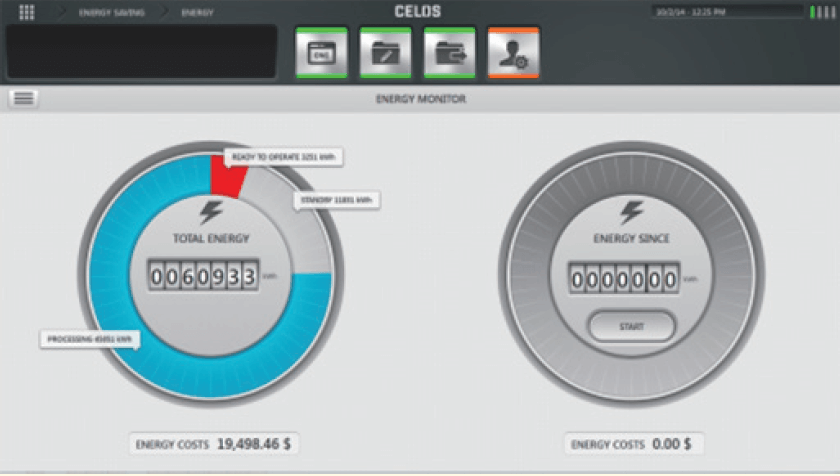

GREEN monitoring

- Power consumption and CO₂ emissions are visualized on the CELOS operation panel screen

GREEN device

- Bright LED Illumination

GREEN idle reduction

- Power to parts such as the servo motor, main drive, and coolant pump is stopped when the machine is stopped

- Operability screen is turned off if the machine is not operated for a period of time

GREEN control

- Machining time reduced using reduced power pecking cycle

- Quicker standard M code

- Synchronized acceleration/deceleration between main drive and feed shaft

- Coolant discharge controlled using inverter

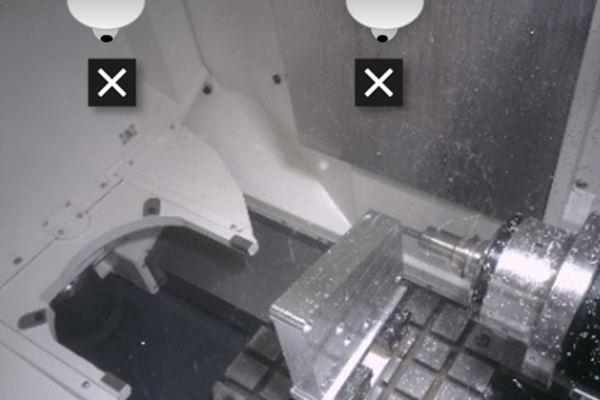

AI chip removal

AI chip removal uses AI to analyze and automatically remove chip accumulations to reduce machine stops and machining defects caused by chips. When the AI recognizes only little chip accumulation, the coolant cleaning stops to reduce the power consumption of the coolant pumps and CO₂ emissions.

Coolant cleaning only when needed

To reduce CO₂ emissions and power consumption

Reduction: Electricity expenses [440,000 JPY]/10 years, CO₂ emissions [12.5 t]/10 years(*)

* Machine operated 16 hours per day, 240 days per year with a coolant cleaning ratio of 30% (calculated using electricity expenses of 15 JPY/kWh and CO₂ emissions coefficient of 0.424 kg/kWh)

Coolant is discharged when chip accumulation is high

Coolant is discharged when chip accumulation is high Coolant discharge is automatically stopped when chip accumulation is low

Coolant discharge is automatically stopped when chip accumulation is lowzero-sludgeCOOLANT

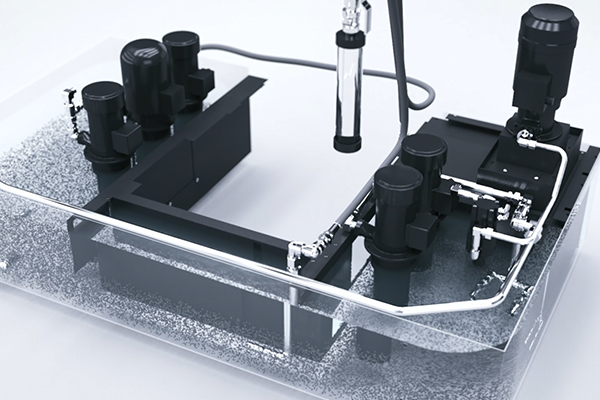

This coolant treatment system efficiently recovers sludge from coolant tanks. First, coolant is discharged from nozzles in the coolant tank and the entire tank is stirred to prevent sludge accumulation. Next, all sludge is sucked up by pumps and cleaned through a high-precision filter, before being returned to the tank. The prevention of chip build-up in the tank and the growth of bacteria helps avoid spoilage and extends the coolant change cycle, while extended coolant life directly benefits waste avoidance and the reduction of CO₂ emissions associated with the disposal of the coolant.

Reduced cleaning frequency = Work environment improvement

Less regular [cleaning work] for coolant tanks

Cleaning a coolant tank requires a lot of work and poses health risks. Consequently, reducing the frequency of cleaning can prevent injury and help to improve the work environment and motivation.

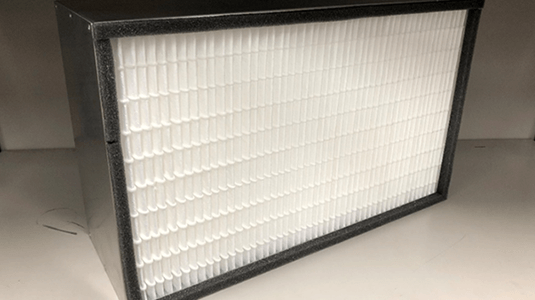

zeroFOG

As coolant mist is generated during metal processing, this built-in mist collector efficiently collects mist to maintain the cleanliness of the factory air with its high-performance final filter according to the HEPA filter standards (of catching at least 99.7% of fine particles of 0.3 μm in size). In addition, thanks to optimized component design, zeroFOG contributes to power saving of other peripheral equipment as well.

Only simple maintenance required for clean air exhaust

Efficient mist collection with little maintenance to support the environment

Cleaning level equivalent to that of an [air purifier]

Trapping efficiency: [0.3 μm 99.97%] or higher (HEPA)

Automatic [reverse cleaning] of primary filter

Disassembly/cleaning: [Not required]