- HOME

- SUSTAINABILITY

- Environment

- Functions & Machine Tool Lifecycle

- DMG MORI’s Business Sites

DMG MORI’s Business Sites

Internal initiatives for energy conservation

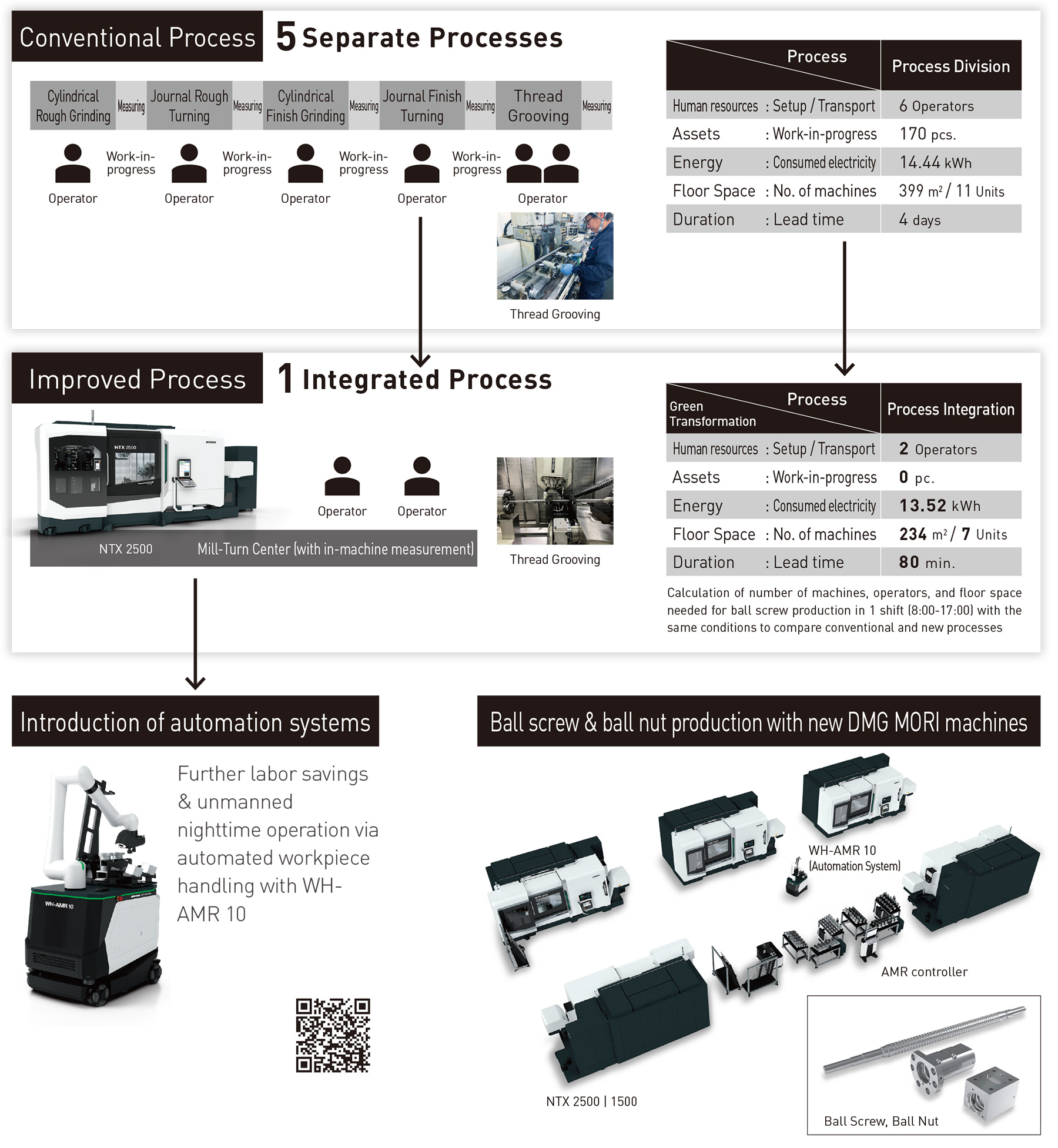

The Company is promoting MX for internal productivity improvement with the same care as for its customers, aiming to make its production processes lean and clean through innovation and digital solutions.

To modernize its production, the Company has continuously introduced process integration machines for in-house manufacturing of key machine tool components, thus reducing work-in-progress inventory, CO₂ emissions, and factory floor space. Over the past 10 years, the replacement of more than 300 machine tools with 56 process integration machines has cut CO₂ emissions by 45% at Iga Campus.

In addition, by embodying MX at its own business sites, the Company itself serves as showrooms to introduce customers to the MX concept.

Renewable Energy Use

Renewable energy on a global scale

DMG MORI strives to increase the utilization rate of renewable energy throughout the Group, e.g., by expanding in-house solar power generation. The Company has been promoting CO2-free electricity throughout the Group since 2020, and Iga Campus made the transition in April 2021. At Iga Campus, the Company is further increasing the use of renewable energy by introducing solar power generation equipment on top of the approx. 130,000 square meter factory roof with a capacity of approx. 13.4 megawatts to cover about one third of Iga Campus’s annual electricity demand. Group-wide, the Company is launching solar power generation systems at its plants in Pfronten (Bavaria, Germany), Seebach (Thuringia, Germany), Davis (California, USA), Tianjin (China), at DMG MORI CASTECH (Izumo City, Shimane Prefecture, Japan), and more.

Click here for a look at the solar panels at Iga Campus.

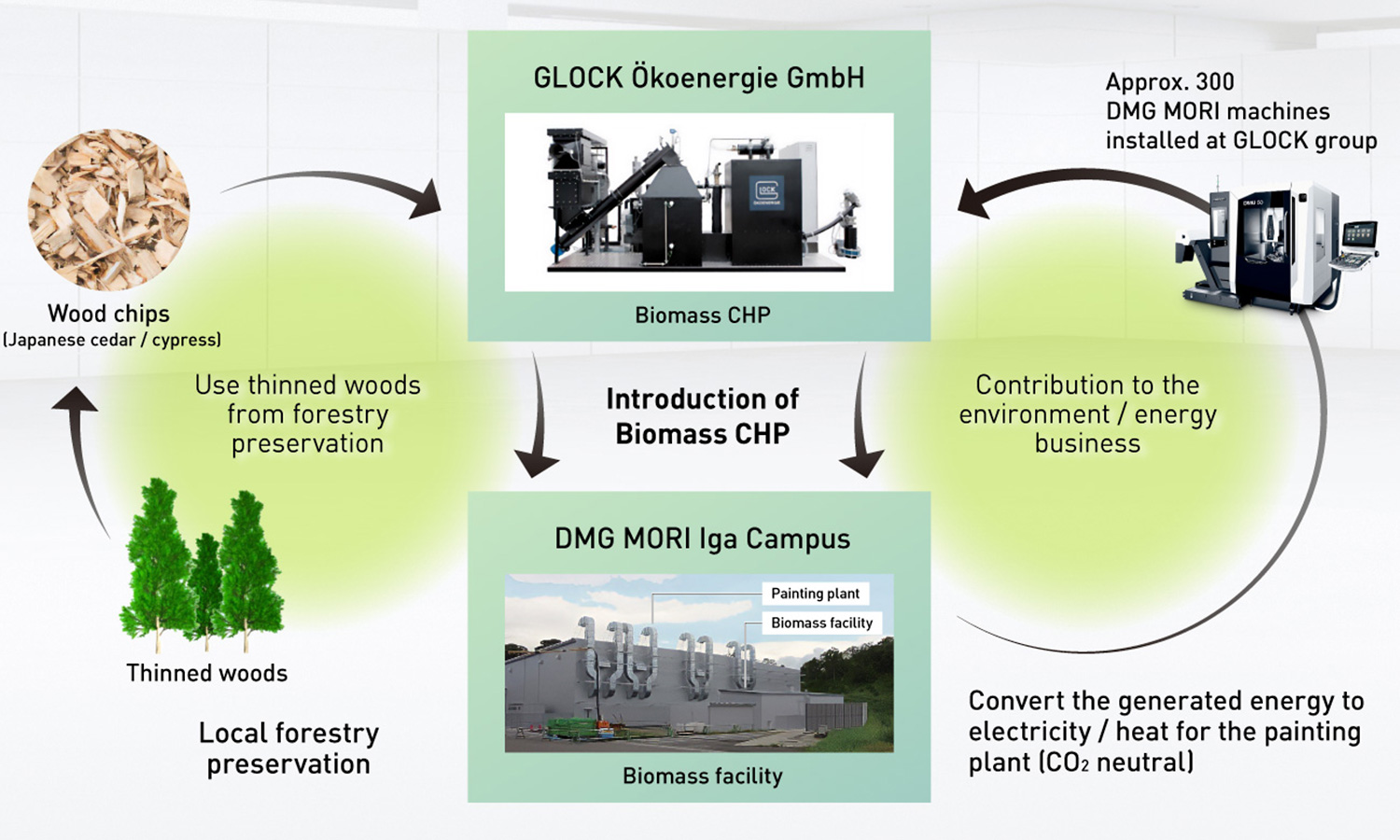

Introduction of biomass power generation system

In 2021, the Company introduced a biomass thermoelectric supply system in the paint factory on Iga Campus. The system‘s high efficiency and energy-saving performance allows 96 percent of the output energy to be used as electricity and heat, thus benefitting the local plant by reducing its energy consumption and CO₂ emissions as the system itself is fueled by bio-derived wood chips. As a result, the Company contributes to protecting the environment by the use of thinned wood and supports local lumber companies in the process. Still, this is but one of our contributions to the environment and local communities. Finally, the incineration ash produced by biomass power generation is effectively used as fertilizer in vineyards.

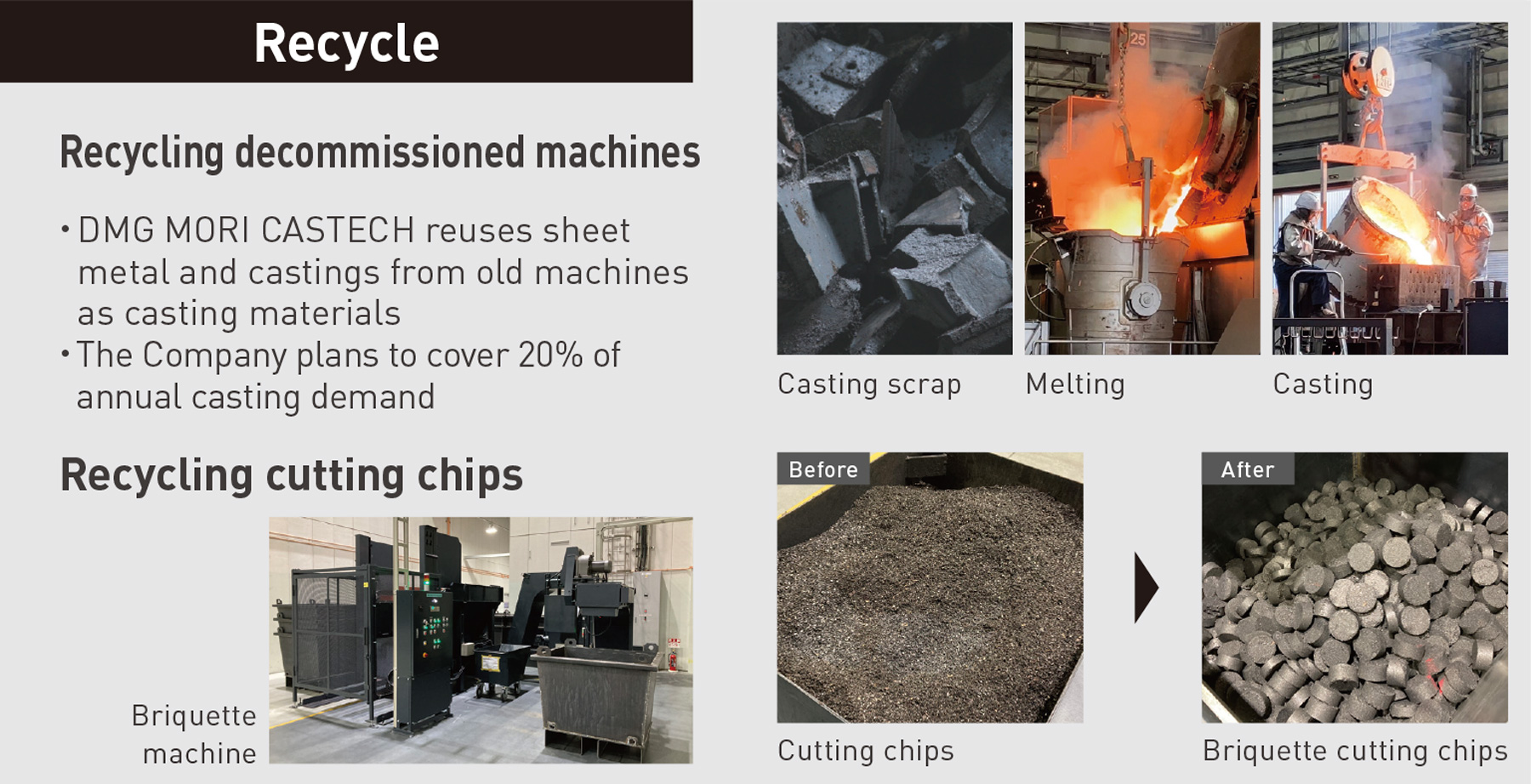

Waste Management

As part of the manufacturing industry, the Company cannot avoid the generation of waste when executing its business. Therefore, the Company recognizes a strong relationship between initiatives for waste reduction and efficient use of materials and energy resources, which have the joint potential of greatly contributing to environmental preservation. The DMG MORI Group is committed to making effective use of resources and engages in efforts to manage, reduce, and recycle waste to work toward a sustainable recycling-oriented society.

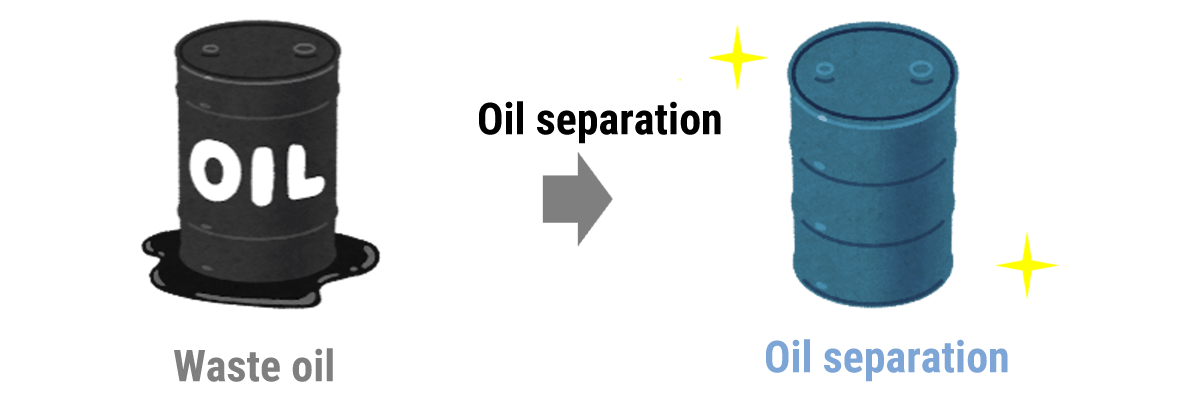

Specifically, this means collecting scrap from aging and discarded machine tools and casting processes to be reused for the creation of new castings at DMG MORI CASTECH, as well as filtering waste oil to reuse its components as recycled heavy oil fuel.

Use the heat generated when burning as energy (thermal recycling). Use the heat generated when burning as energy (thermal recycling). |

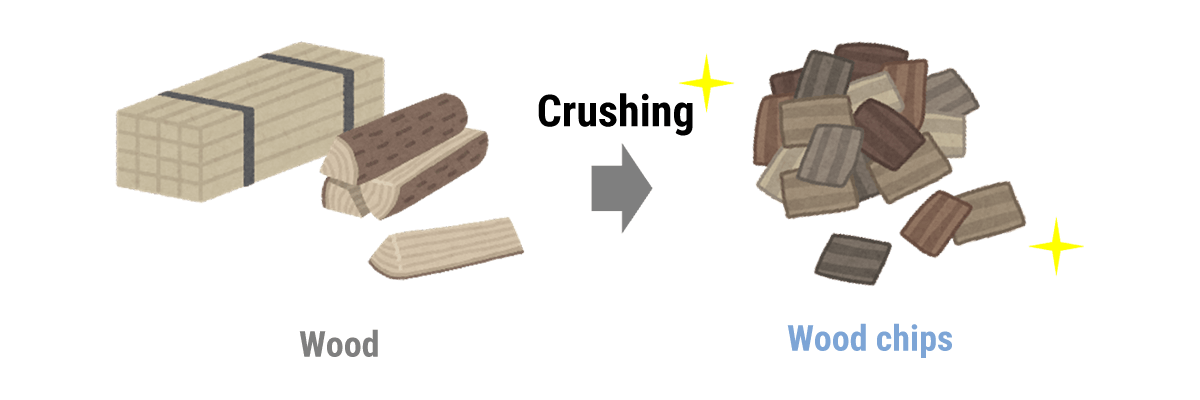

Crushed wood is reused as wood chips, which are used as fuel. Crushed wood is reused as wood chips, which are used as fuel. |

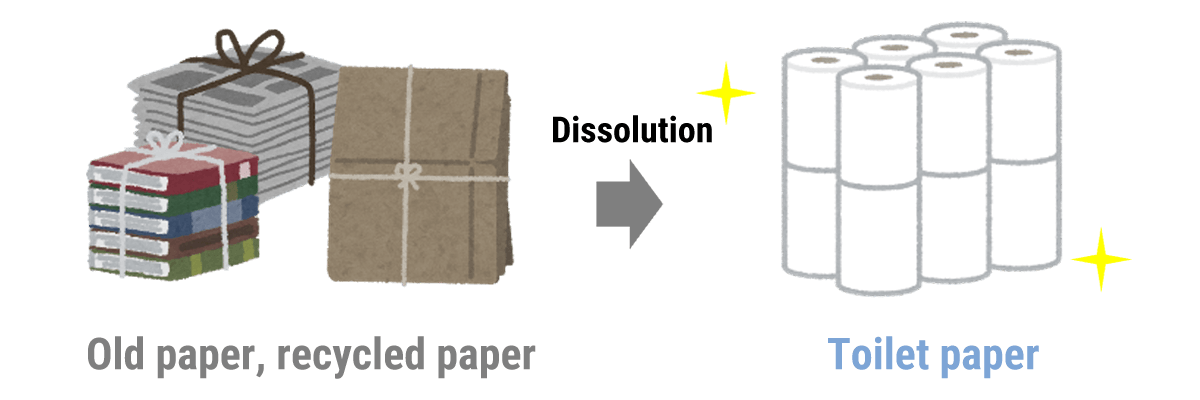

Dissolve and reuse as toilet paper. Dissolve and reuse as toilet paper. |

Oil separation allows waste oil to be recycled into heavy fuel oil. Oil separation allows waste oil to be recycled into heavy fuel oil. |

Sustainability starts within

The Company has adopted LED lighting in its offices to reduce power consumption and promotes paperless operations by eliminating fax machines and utilizing TULIP* at its production sites.

*TULIP: A platform to promote the next generation of manufacturing. By digitizing manuals and quality check sheets and integrating with measurement instruments, TULIP enables users to improve processes and drive digital transformation directly from the shop floor.