Press Release

DMG MORI and HAIMER strengthen global strategic partnership:

Integration of the HAIMER “Tool Room of the Future” develop-ment to DMG MORI sites, including full automation solutions in Iga and a joint global software distribution agreement

Nagoya and Iga (Japan), October 24th, 2025: DMG MORI Co., Ltd. and HAIMER GmbH announced an expansion of their long standing strategic cooperation to accelerate tool room digitization, automation and global software distribution. The agreement extends joint activities across DMG MORI showrooms, technical centers and production facilities worldwide to the benefit of their joint global customers.

Successful machining requires both powerful machines and highly-precise periph-eral technology, which ensures that the precision is transferred from the spindle right to the edge of the cutting tool. That is why the cooperation between DMG MORI, a global leader in machine tools and HAIMER, global leader in high-precision tool-ing, shrinking, presetting and balancing technology, has been very successful and trustworthy for almost twenty years. Now this cooperation incorporates the evolution of the industry to machining transformation (MX) and digital transformation (DX) by adding latest HAIMER software to DMG MORI Qualified Products (DMQP) for worldwide resale.

Dr. Masahiko Mori, President of DMG MORI Co., Ltd., highlights the idea of the next step of the partnership in general: “Working closely with HAIMER as a long-term partner advances our MX and DX strategy by integrating worldwide leading shrink fit, balancing and presetting machines including high precision tooling, tool room au-tomation and software solutions to our global customers. As a leading machine tool company, we deliver full process integration and digital transformation in our DMQP program together with HAIMER. This step will accelerate digital twin connectivity across our machine ecosystem.”

For Andreas Haimer, President of the HAIMER Group, the digital connectivity in HAIMER’s tool room solutions is crucial for the extended partnership:

“We will bring our global partnership to the next level by implementing the “Tool Room of the Future” concept with i4.0 presetting, shrinking and balancing including our digital tool & data management software WinTool and Tool Room Manager as well as our smart vending Toolbase solutions to all DMG MORI facilities, showrooms and technology centers worldwide. Our joint customers can easily buy the complete HAIMER product range in the DMQP program through DMG MORI and integrate our products, with the option of financing, at the time of their machine tool investments.”

In detail, the agreement comprises the roll-out of the “Tool Room of the Future”, i.e. joint deployment of industry 4.0 presetting, shrink fit and balancing machine solu-tions connected with HAIMER software at the global DMG MORI headquarter in To-kyo, as well as at the key production sites in Iga, Japan, Pfronten, Germany and other DMG MORI locations worldwide. In the HAIMER “Tool Room of the Future” every single assembly step is traced back, controlled and confirmed by the Tool Room Manager software. The digital twins are created by WinTool and the assembly jobs including cutting tool tolerances are sent to the presetting, shrinking and bal-ancing devices for seamless data connectivity. The cutting tool reordering can be fully automated with the Toolbase solutions.

Automation Cube One - Game-changer for the DMG MORI Iga production plant

Furthermore, at the Iga production facility recently the HAIMER Automation Cube One was introduced for fully automated, lights out tool assembly set-ups with Mag-nescale components, assuring the highest accuracy.

This automated shrinking and presetting cell with cobot and 12 axis’ is the ideal so-lution for reliable and efficient tool assembly in a high volume production environ-ment. In conjunction with HAIMER’s high quality shrink fit holders, the installation of the HAIMER Automation Cube One proved already to be a game-changer for the Iga production site as Kazutoyo Moriguchi, Senior Executive Officer Production En-gineering and Vice President DMG MORI Iga Co. Ltd. explains:

“We have already seen a significant productivity increase of 30% and more in our own production by switching conventional Japanese milling and collet chuck sys-tems into HAIMER shrink fit technology a few years ago. Now with the investment of the Automation Cube One we can take the next step, fully automate the tool room and run lights out to overcome the skills gap.”

Global distribution of HAIMER’s digital solutions by DMG MORI Technium

At the EMO Hannover 2025 trade fair HAIMER, DMG MORI Technium and WinTool, marked the beginning of a strong partnership – with the goal of shaping the future of digital Tool Management. On the DMG MORI booth WinTool has been introduced as new digital solution for tool and data management and DMG MORI Technium will resell WinTool globally, providing digital tool management and digital twin connec-tivity to 20+ CAM systems for their mutual customers.

Kentaro Blumenstengel, Executive Officer DMQP and President of DMG MORI Technium emphasizes: “HAIMER has been always our most important DMQP part-ner for Tool Room automation and digitization. Now we have extended this partner-ship with a global software distribution agreement through DMG MORI Technium to resell WinTool, Tool Room Manager and all HAIMER software solutions to our cus-tomers.”

Benefits for Japanese and global customers

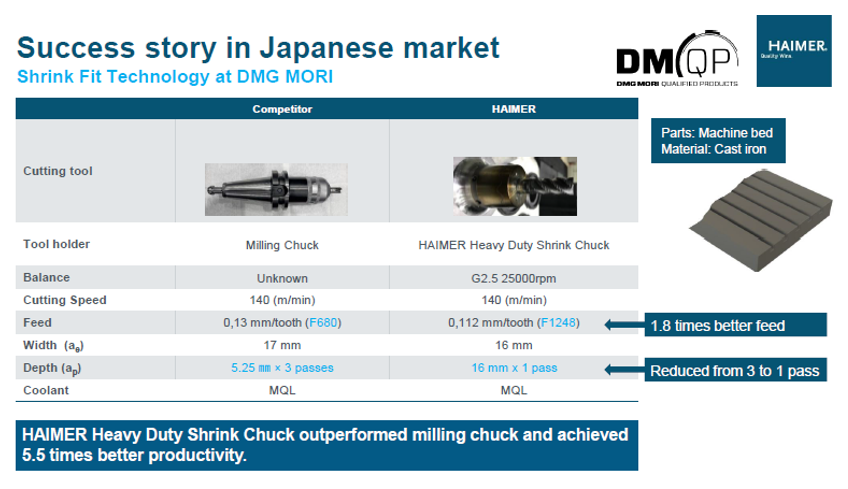

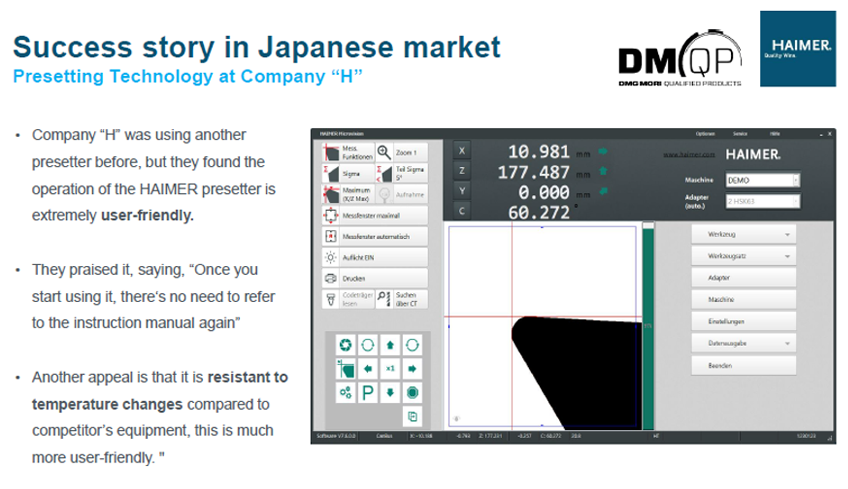

Summarizing the new level of partnership in Japan and globally, HAIMER Japan K.K. President Koichi Nosaka, points out advantages of proven HAIMER solutions for more process reliability and productivity on the shopfloor which manifested in recent Japanese customer success stories:

“Our Japanese and global customers can benefit from this partnership to easily ac-cess all our products through DMG MORI. We have seen at joint customers in Japan that HAIMER balancing systems have extended their spindle lifetime on critical ap-plications by up to 300%. Also introducing our Microset presetting technology to large Japanese automotive companies has resulted in higher accuracy, easier soft-ware operations and much fewer calibration cycles due to the thermally stable cast iron base of our machines.”

Entering into an extended level of global strategic cooperation (from left to right):

Koichi Nosaka (President HAIMER Japan K.K.), Andreas Haimer (President Haimer Group), Dr. Masahiko Mori (President of DMG MORI Co., Ltd.) and Kentaro Blumen-stengel (Executive Officer DMQP and President of DMG MORI Technium)

In conjunction with HAIMER shrink fit chucks the HAIMER Automation Cube One proved to be a game-changer at the DMG MORI Iga production site.

From left to right:

Andreas Haimer (President Haimer Group), Kazutoyo Moriguchi (Senior Executive Officer Production Engineering and Vice President DMG MORI Iga Co. Ltd.) and Koichi Nosaka (President HAIMER Japan K.K.)

DMG MORI also successfully replaced milling chucks with HAIMER shrink fit hold-ers seeing significant productivity increases of up to 5,5 times. Kazutoyo Moriguchi, Senior Executive Officer Production Engineering and Vice President DMG MORI Iga Co. Ltd. explains: “We have already seen a significant productivity increase of 30% and more in our own production by switching conventional Japanese milling and collet chuck systems into HAIMER shrink fit technology a few years ago.”

Microset presetting technology helped large Japanese automotive companies to ob-tain higher accuracy, easier software operations and much fewer calibration cycles due to the thermally stable cast iron base design.

About HAIMER

HAIMER is a family-run, medium-sized company based in Igenhausen near Augsburg, Ba-varia. We develop, manufacture and distribute innovative, high-precision products for metal cutting, serving industries such as tool and mold making, aerospace, medical technology, energy, and general mechanical engineering. Our product portfolio includes a wide range of tool holders in all common interfaces and lengths, solid carbide cutting tools, shrink fit and balancing machines, 3D measuring instruments, as well as HAIMER Microset tool presetting devices.

Of the 800 employees worldwide, around 500 work at the production site in Igenhausen and Motzenhofen equipped with state-of-the-art machinery and a very high degree of automation with a high level of vertical integration. At the second HAIMER production site in Bielefeld, 50 employees manufacture the HAIMER Microset presetters. The experienced, dynamic and highly qualified employees guarantee HAIMER's renowned top quality "made by HAIMER". As an active training company with more than 50 apprentices and a high retention rate, HAIMER is already securing its future skilled workforce today while also contributing to the education of young people and the long-term success of the region. As the European market leader in tool clamping technology with a daily production capacity of approx. 4,000 tool holders, HAIMER places great importance to the technological lead of its products, which is why 8 to 10% of annual revenue is invested in research and development. The daily drive to be better fits perfectly with the company's philosophy: Quality wins.

| Haimer GmbH | DMG MORI Global Marketing GmbH |

|---|---|

| Tobias Völker | Katharina Contu |

| Weiherstraße 21 D-86568 Igenhausen |

Walter-Gropius-Str. 7 D-80807 München |

| Tel.: +49 82 57 99 88 346 | Tel.: +49 89 2488 359 21 |

| E-Mail: tobias.voelker@haimer.de | E-Mail : katharina.contu@dmgmori.com |

| www.haimer.com | www.dmgmori.com |