Press Release

Launch of the NLX 2500 | 1250 2nd Generation

Realize MX with process integration & automation!

DMG MORI CO., LTD. (hereinafter referred to as “DMG MORI”) has added the NLX 2500 | 1250 2nd Generation to its lineup of next-generation turning centers to promote MX (Machining Transformation) with new levels of accuracy and performance for long-shaft-type processing. This marks the newest entry after the launch of the NLX 2500 | 700 2nd Generation last September.

The NLX 2500 2nd Generation incorporates customer feedback and the latest technology for an increased bar material capacity of up to Ø105 mm and an expanded Y-axis stroke of 120 mm. With milling capabilities equivalent to No. 40 machining centers, the machine realizes superior surface quality and efficient chip evacuation for seamless process integration of a wide range of workpieces.

In addition, sliding guideways on the X/Y/Z-axis support high rigidity and excellent vibration damping even during heavy-duty cutting of long workpieces. The new BMT (Built-in Motor Turret) offers superior flexibility with a max. spindle speed of 12,000 min-1 for hard milling of difficult-to-cut materials and high-speed processing of aluminum parts.

We have utilized digital twin technology from the design stage and cooperated with our Group company, Magnescale Co., Ltd., to implement the MAP offset function and realize a C-axis positioning accuracy of 0.001°*1 for straightness, squareness, and contour tracking on machining-center level. With improved C-axis indexing accuracy, we greatly enhance the machine’s gear processing (incl. hobbing and skiving) capability with perfect synchronization between the spindle and rotary tools. Together with the newest thermal design, we reduce internal and external temperature effects and keep radial displacement within 7 µm*2 even during continuous operation for maximum stability.

The NLX 2500 2nd Generation realizes uninterrupted production over long periods of time with thorough solutions against machine trouble*3. These include the zeroFOG*4 mist collector, the large-capacity zero-sludgeCOOLANT*4 tank with integrated self-cleaning function, a high-pressure coolant unit*4, a coolant chiller*4, and the cyclone filter – all of which are integrated into the machine’s compact floor space.

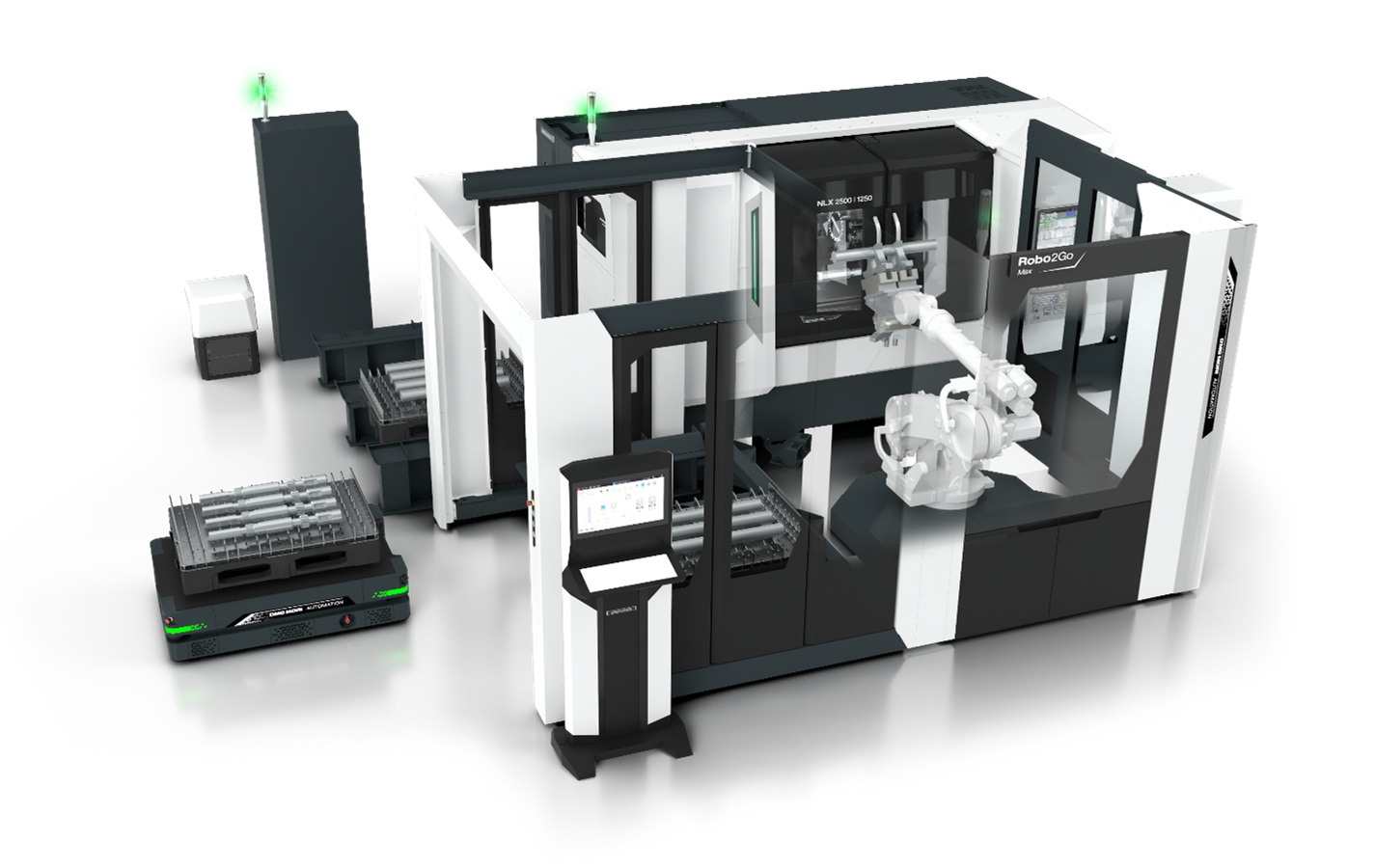

A wide range of options for steady rest, tailstock, right spindle, and more make this the ideal machining solution for long-shaft-type workpieces. For example, customers can automate workpiece handling with the Robo2Go Max work handling system with a max. transfer weight of 115 kg.

The NLX 2500 | 1250 2nd Generation will be on display at “EMO Hannover 2025” from September 22 to 26 at the Hannover Exhibition Center in Germany. Catalogs and a digital twin showroom for EMO 2025 are available on our website*5.

| Product Information | https://www.dmgmori.co.jp/en/products/machine/id=1399 |

|---|---|

| Highlights Video | https://www.dmgmori.co.jp/en/movie_library/movie/id=8397 |

| EMO 2025 Digital Twin Showroom | https://www.dmgmori.co.jp/sp/dtsr/emo-hannover-2025/ |

Main Features

- 1. Stable machining of long workpieces

- Enhanced X/Y/Z-axis sliding guideways & bed design for high rigidity and vibration damping to support heavy-duty cutting

- High-torque/high-output turnMASTER spindle for both left and right spindle

- 2. Process integration for various workpieces

- Increased bar material capacity of up to Ø105 mm & expanded Y-axis stroke of 120 mm

- Improved BMT (Built-in Motor Turret) with high output & 12,000 min⁻¹ rpm for milling performance equivalent to No. 40 machining centers Flexibility for hard milling, difficult-to-cut materials, and high-speed machining of aluminum

- 3. High accuracy

- Optimized structure with digital twin design

- MAP offset by Magnescale for C-axis positioning accuracy of 0.001° (guaranteed value: 0.003°) Contour tracking during milling & improved X-C axis coordinate interpolation accuracy

- 4. High rigidity & thermal stability

- Radial displacement ≦ 7 µm during continuous operation for outstanding machining accuracy*2

- Internal ball screw cooling of X/Y/Z-axis & double anchor support for feed axis cooling and stability

- Stable accuracy through coolant circulation to minimize thermal displacement

- 5. Innovative solutions for chips, coolant, and mist management

- Two-layer coolant tank with high-pressure coolant unit (up to 10 MPa) *4, coolant chiller*4, and cyclone filter

- High tank capacity in a compact footprint

- Efficient mist collection with zeroFOG*4

- 6. Enhanced usability

- Intuitive H2M Interface: ERGOline X with CELOS X Slide the control panel to the side for easy setup & operability

- Choose between MAPPS X or SIEMENS SINUMERIK ONE

- Standard NC-CLAMP for clamping force control on the control panel

- Easy control and monitoring of chuck pressure/stroke

- Seating detection for safe machining of high-mix workpieces

- Frequent maintenance areas designed for easy access (coolant, lubrication, hydraulic filters, etc.)

- 7. Resource- & energy-efficient

- SBT-certified*6 for CO₂ reduction across the whole supply chain

- Facilitates process integration & energy efficiency

- Thorough coolant &chip management for extended coolant life

- Less frequent coolant change & tank cleaning

DMG MORI will continue to address customer needs with highly functional and reliable product releases worth your investment.

| Turning Center | |

| NLX 2500 | 1250 2nd Generation | |

| EV, Aircraft, Space, Semiconductor, Industrial Equipment, etc. |

*1 Guaranteed value: 0.003°(12 arcsec)

*2 Based on results under temperature change of 8°C. Value not guaranteed.

*3 Machine trouble caused by cutting chips, coolant, and mist that hinder continuous operation.

*4 Option

*5 Catalogs are available only for web members. Register as a member (free of charge) to view exclusive contents.

*6 Science Based Targets: greenhouse gas emission reduction targets set by companies for the next 5 to 15 years, consistent with the

levels required by the Paris Agreement (which aims to limit the global temperature increase to well below 2°C above pre-industrial

levels and 1.5°C below pre-industrial levels).

※DMG MORI CO., LTD., NLX, Machining Transformation, CELOS, ERGOline, BMT, Magnescale, zero-sludge, zeroFOG, and

Robo2Go are registered trademarks or trademarks of DMG MORI CO., LTD.

NLX 2500 | 1250 2nd Generation

NLX 2500 | 1250 2nd Generation + Robo2Go Max + AMR 2000 (system example)

ERGOline X with CELOS X (panel movement)

NLX 2500 | 1250 2nd Generation (workpiece examples)