Press Release

Flexible workpiece & pallet handling for variable-mix/variable-volume production with “MATRIS WPH”

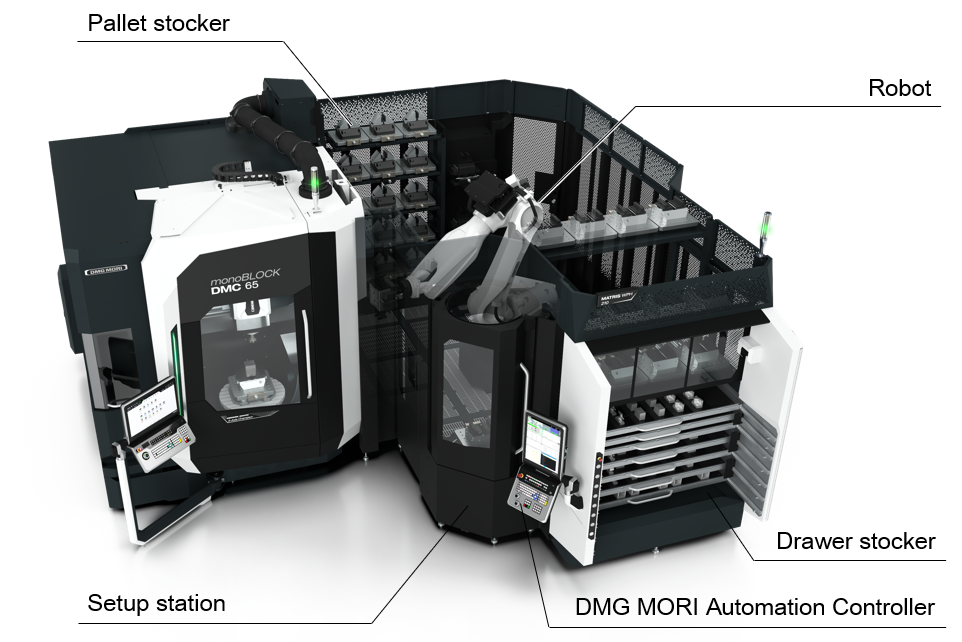

DMG MORI CO., LTD. (hereinafter referred to as “DMG MORI”) has developed its next-generation automation system “MATRIS WPH” for flexible workpiece and pallet handling to support your production.

In recent years, the increase of high-mix, low-volume production has greatly advanced process integration and automation. However, small lot sizes and frequent fixture changes pose a challenge to long-period unmanned production of multiple types of workpieces only by automating workpiece handling. On the other hand, the automation of pallet handling remains difficult, too, as customers face increased costs from the need to purchase fixtures according to the number of pallets in use.

MATRIS WPH is our newly developed automation package system that addresses these challenges by combining the handling of workpieces and pallets in a single system for flexible production. Its robot comes in two variants: the MATRIS WPH 70 (with max. payload of 70 kg) and the MATRIS WPH 210 (with max. payload of 210 kg*1). The system is controlled via the DMG MORI Automation Controller next to the drawer stocker and offers an intuitive user interface for no-code robot operation and operating status checks. In addition, MATRIS WPH is equipped with movable storage shelves for various types of fixtures, a workable setup station, and a large-capacity drawer stocker. Thanks to the smart system design and the use of automatic robot teaching by touch probes, customers can look forward to swift system start-up in half the time than previous MATRIS models.

DMG MORI will exhibit MATRIS WPH at EMO 2025 at the Hannover International Trade Fair in Germany from September 22 to 26. For further information, please take a look at our product catalog and EMO 2025 digital twin showroom.*2

Main features

1. Flexible system configuration according to customer needs

- 1 robot for flexible handling of workpieces and pallets

- Select your robot payload: 70 kg or 210 kg for any workpiece type*1

- MATRIS WPH 210 supports up to 38 pallets depending on the pallet size*3

- With large-capacity drawer stocker for raw and finished parts

2. Long periods of unmanned production

- Centralized oil pan for coolant collection across the whole system, with easy, tool-free maintenance

- Thorough solutions to realize true unmanned production across long periods, incl. measures against cutting chips, coolant, and mist

- AI Chip Removal for automated chip cleaning to avoid manual work*3

- zero-sludgeCOOLANT for efficient stirring and collection of tank sludge

- zeroFOG for efficient collection of cutting mist

3. Compatible with a wide range of machine tools

- Compatible with various machines including 5-axis DMU/DMC, monoBLOCK, eVo, CMX, and NVX series

- Enables system integration between two machines

- 50% shorter setup time than previous models, for a swift system start-up

4. Operability

- Controlled via the DMG MORI Automation Controller next to the drawer stocker

Intuitive interface for quick job setup and status monitoring - Setup station on the front side of the machine

Built-in vacuum unit*3 for efficient cleaning

DMG MORI will continue to address customer needs with highly functional and reliable product releases worth your investment.

| Automation solution | |

| MATRIS WPH 70, MATRIS WPH 210 |

*1 This differs from the max. payload on the pallet. The max. payload on the pallet depends on the pallet size.

Please refer to the catalog for details.

*2 Catalogs are available only for web members. Register as a member (free of charge) to view exclusive contents.

*3 Option

※DMG MORI CO., LTD., MATRIS, zero-sludge, and zeroFOG are registered trademarks or trademarks of DMG MORI CO., LTD.

DMU 50 3rd Generation + MATRIS WPH 70 (exterior)

DMC 65 monoBLOCK + MATRIS WPH 210 (system exapmle)