Press Release

Launch of the NTX 3rd Generation

Realize MX with next-level precision & productivity!

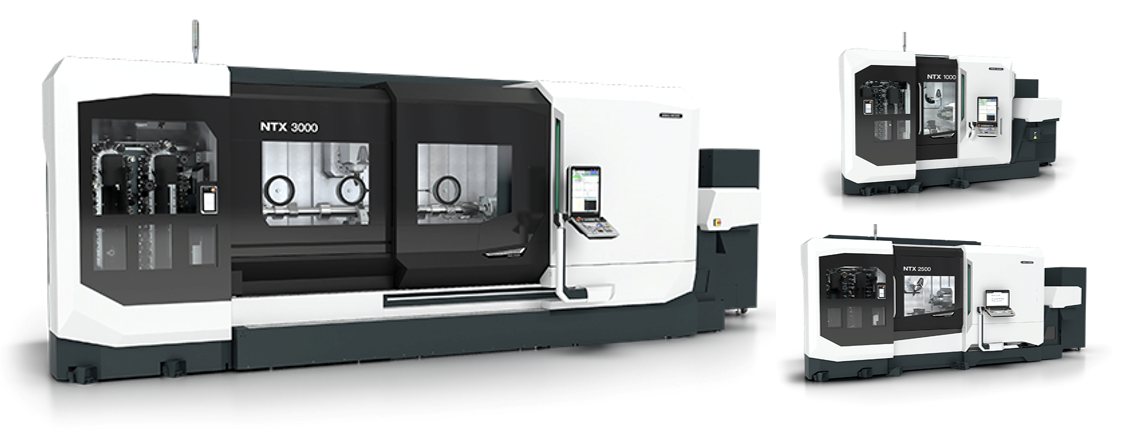

DMG MORI CO., LTD. (hereinafter referred to as “DMG MORI”) has launched the newest generation of mill-turn machining centers: NTX 1000 / 2000 / 2500 / 3000 3rd Generation (“NTX 3rd Generation”).

With improved design and the newest technology, we proudly present the perfect machine series for accelerating customers' MX (Machining Transformation) with new levels of precision and productivity by offering a range of beloved options now as standard*1.

The NTX series of mill-turn machines combines high machining capacity with the ability to integrate processes from separate turning/machining centers to efficiently machine a wide range of workpieces and lot sizes. Since its launch in 2010, our NTX machines have enjoyed popularity in various industries, such as aerospace, medical, energy, EV, mold, semiconductor, and precision machinery. Recently, more and more customers have been realizing the benefits of process integration with mill-turn machines to solve labor shortages and produce highly precise and complex workpieces in a sustainable manner. DMG MORI developed the NTX 3rd Generation as a next-level machine capable of meeting the needs of customers and greatly accelerating their MX.

In addition, the new generation comes with various spindle types as standard: the high-rigidity, 400V-powered turnMASTER spindle, the compactMASTER turn-mill spindle, and the turretMASTER*2 spindle with high milling capability. All spindles benefit from full closed-loop control (scale feedback) on all axes and thorough thermal deformation suppression by cooling water circulation in the machine body to drastically improve cutting ability and accuracy. In addition, the "ERGOline X with CELOS X" user interface combines touch-panel and keyboard inputs to allow for easy and intuitive operation, while the “Setup Assistant” guides your inputs and reduces setup time. Furthermore, gear cutting, grinding, and other machining processes that used to rely on special machines, as well as measurement processes on CMM-level, can now be integrated into a single NTX 3rd Generation machine thanks to DMG MORI Technology Cycles.

On the automation side, we offer MATRIS, gantry loaders, bar feeders, and more. Also, we address machining troubles due to chips, coolant, and mist that pose a hurdle to long periods of continued operation: Highly durable stainless-steel covers prevent chips from accumulating inside the machine; the vertical high-capacity coolant tank zero-sludgeCOOLANT pro efficiently collects both sludge and mixed oil; and zeroFOG absorbs machining mist. The NTX 3rd Generation comes with these solutions as standard and enables reliable, continuous operation of machines and automation systems over long periods of time, thus further boosting customers’ productivity.

In addition, thorough management of coolant and cutting chips helps extend coolant life to reduce CO2 emissions from the incineration of coolant waste. With our in-house-developed, high-efficiency transformer as well as GREENmode and the integration of coolant pumps, we allow customers to further save power and reduce their annual energy consumption by 12%.

As a result, DMG MORI's latest series of mill-turn machines, the NTX 3rd Generation, integrates processes from milling and turning to gearing, grinding, and measuring, to realize long hours of continuous operation in the most sustainable and profitable manner.

Take a look at our website for product catalogs and videos. *3

- Catalog: NTX 1000 3rd Generation

- Catalog: NTX 2000 / 2500 / 3000 3rd Generation

- Highlights Video: NTX 2000 / 2500 / 3000 3rd Generation

Main Features

①Improved machining performance & accuracy

- turnMASTER with 400V-performance available on both left and right spindle*2

- ・ compactMASTER combines a short turn-mill-body of only 350 mm*5

with high-speed/high-torque operations at 20,000 min-1 *2 - turretMASTER*2 now with improved milling capability and accuracy

- Coolant circulation inside the machine body against thermal deformation

- All axes with full closed-loop control (scale feedback) as standard for high positioning accuracy

- More than 39*4 Technology Cycles to integrate difficult processes on 1 machine

- CELOS Chatter Control*2 allows the selection of recommended spindle speeds to prevent chatter vibration

- Grinding*2 allows grinding processes on a universal machine tool with dialog-based programming and parameter input, incl. programs for dressing and tooling

②Improved operability & setup

- Equipped with ERGOline X (HMI) for intuitive control

- Tool magazine for up to 246 tools*2,6

- Magazine control panel available as standard for improved tool setup

- With NC-Clamp as standard to command chuck clamping force from the control panel,

incl. a workpiece detection function to avoid errors during high-mix production

③In-machine measurement supported by high machine accuracy

- Measurement by radio wave transmission touch sensor with repeatability of 0.25 µm or better

- In-machine tool presetter with less interference than conventional types as standard

- Use the automatic in-machine measurement system Tool Visualizer

for automatic tool 3D modeling and chip winding/breakage detection

④Support of various automation solutions*2

- MATRIS: customizable robot system with standardized peripheral equipment

- MATRIS Light: fenceless robot system on a trolley for use next to humans

- WH-AMR 10: automates in-factory logistics for collaboration with humans

- GX Loader: fast automation system for part loading/unloading during mass production

- Bar feeder: for automated bar machining together with a workpiece unloader

DMQP (DMG MORI QUALIFIED PRODUCT) with total support from selection to delivery and maintenance

⑤Standard solutions against cutting chips, coolant, and mist

- Stainless steel covers and shower coolant prevent in-machine chip accumulation

- Chip conveyor with drum filter for improved coolant-chip-separation

- Vertical high-capacity coolant tank zero-sludgeCOOLANT pro for long periods of continuous operation

- Mist collection by zeroFOG

⑥Efficient use of energy & resources

- Thorough coolant management and chip disposal to extend coolant life

Reduced CO2 emissions from incineration of coolant waste by 1.7 t*7 - In-house-developed, high-efficiency transformer & GREENmode

to suppress unnecessary power and promote sustainable production - DMG MORI is SBT-certified and implements initiatives*8 to reduce CO2 emissions throughout the supply chain.

DMG MORI will continue to address customer needs with highly functional and reliable product releases worth your investment.

| NTX 1000 3rd Generation / NTX 2000 3rd Generation / NTX 2500 3rd Generation / NTX 3000 3rd Generation | |

| Aerospace, Medical, Energy, EV, Die & Mold, Semiconductor, Precision machinery, etc. |

*1 The NTX 500 also comes standard with the options standardized in the NTX 3rd Generation.

*2 Option

*3 Catalogs are available only for web members. Register as a member (free of charge) to view exclusive contents.

*4 Supported items may vary depending on the model specifications. For details, please contact our sales representative.

*5 Only for C6 or HSK-A63. For NTX 1000, the standard specification is C5 or HSK-A50. C6 or HSK-A63 are available as options.

*6 NTX 100 allows storage of max. 114 tools.

*7 Calculated as an emission factor of 2.92 tCO2/t for waste oil incineration when the entire tank volume (580 L) is re-circulated once every 6 months.

*8 Science Based Targets: greenhouse gas emission reduction targets set by companies for the next 5 to 15 years, consistent with the levels required by the Paris Agreement (which aims to limit the global temperature increase to well below 2°C above pre-industrial levels and 1.5°C below pre-industrial levels).

※DMG MORI CO., LTD., DMG MORI, Machining Transformation, turnMASTER, compactMASTER, ERGOline, Technology Cycle, zero-sluge, zeroFOG, MATRIS, and DMQP are registered trademarks or trademarks of DMG MORI CO., LTD.

※On the left: NTX 3000 | 3000. On the right (from the top): NTX 1000, NTX 2500 | 1500.

NTX 3rd Generation

NTX 1000 3rd Generation + MATRIS

NTX 1000 3rd Generation (interior)

Process integration (incl. gearing, grinding, etc.)